Sweden has very good geographical conditions for using renewable energy resources. Historically, about half of the country’s electrical energy is produced by hydro power plants, but now, in addition to this, the government has set ambitious plans for wind power development. Developing renewable resources presents a set of technological challenges including network capacity issues, as overhead lines in the Swedish networks threaten to become bottlenecks because of the rapid increase in wind power installations.

The capacity of an overhead line is limited by the temperature of the conductor and corresponding sag. Historically, capacity has been seen as a static parameter determined by assuming the worst-case weather conditions as a result of the cooling effect on the line. This is a conservative but safe way to determine the maximum current-carrying capacity of a conductor.

In areas subject to high winds, it seems reasonable to consider local weather conditions and the wind cooling effect as a basis for deciding the current rating of an overhead line. With a real-time measurement system for local weather parameters, and line temperature or conductor sag at the predicted hot spot on the line, it is possible to assign a dynamic line rating (DLR). With the implementation of DLR comes the possibility of measuring and controlling wind power production. This method ensures the current-carrying capacity of overhead lines in areas subject to high winds is not loaded above the assigned rating.

Overhead Line Ratings

Vattenfall Distribution Nordic is the largest distribution system operator (DSO) in Sweden and the owner of about half of the Swedish subtransmission network, in addition to 20% of the medium- and low-voltage networks. The subtransmission network comprises 15,000 km (9320 miles) of overhead lines and almost 900 substations. Vattenfall receives a large number of requests for the connection of wind farms to its medium- and low-voltage networks. Load-flow analysis often confirms one or more of the overhead lines will become overloaded during the hours of high wind power generation.

Sweden has relatively cold winters and the electricity networks are normally well designed with adequate capacity to supply electrical heating. With the exception of industrial loads, the load pattern is very predictable and has a load characteristic that negatively correlates with temperature during peak loads in the winter period. It is fortunate that low ambient air temperature is enough to cool overhead line conductors during the winter.

The connection of an excessive number of wind farms to an overhead line network would result in the capacity limit occurring during the warmest summer days when wind power production is high, instead of during the winter when loads are high. The overhead line capacity (static rating) is based on the rather conservative assumption the wind speed, perpendicular to the conductor, is only 0.6 m/sec (2 ft/sec), occurring during the hours with high wind power generation. However, even a small increase in wind speed higher than 0.6 m/sec (2 ft/sec) would significantly increase the capacity of the line.

Vattenfall has performed case studies where wind data from wind turbines, measured at nacelle height, has been compared with wind data from nearby overhead line corridors. Based on those studies, the DSO found the wind cooling effect on the line could be taken into consideration with higher accuracy. This could help to make a business case for upgrading the conservative static ratings on overhead lines in wind power production areas for planning purposes and the introduction of DLR based on measurement systems for network operational purposes.

Dynamic Rating Techniques

The practice of assigning to overhead lines dynamic ratings that take into account weather conditions is not new. Weather stations have been used for this purpose for more than 30 years. Different rating techniques are available on the market and new concepts are still developing. The algorithms used for determining dynamic ratings are generally based on CIGRE or IEEE methods.

Many systems are sold as full-concept solutions with software while others offer individual solutions for the buyer. The largest difference between products from different manufacturers is the parameters that are measured and used as input in the calculations.

Some systems rely on net temperature differences that include more than one weather parameter, whereas other systems measure all weather parameters. Another difference is which parameter is measured to represent the conductor temperature; the conductor temperature can be measured at a single position or at several positions distributed along the line. Tension, sag, inclination or a technique based on vibrations also can be used to represent the overhead line temperature. These various systems are at different development stages and some require physical operations on the line, whereas others can be installed live line, that is, without taking the line out of service.

Vattenfall’s Pilot Project

The objective of Vattenfall’s pilot project was to perform a full-scale test of the DLR concept on one of three 44-kV overhead line feeders to an area with a huge quantity of wind power production, resulting from the connection of wind turbines having an installed capacity of some 80 MW. The peak load in the same area was 47 MW.

On receipt of a new connection request for an additional four 2.05-MW Enercon E82 Wind Turbines at Rangeltorp (two in the first stage), it was necessary to undertake detailed analysis to identify capacity margins and the predicted bottlenecks situations. As a result of Vattenfall’s planning criteria, no further wind power connections could be accepted in this area without reinforcing the existing 44-kV overhead lines. This request also was the last in this particular area because of a new, more restrictive approach to statutory permissions, which designated wind-power-free zones near air bases.

The findings from load and production simulations for the Rangeltorp site confirmed overloading of the 44-kV overhead lines during times of high wind generation production and low loads. However, if the wind cooling effect on the overhead line were considered, the risks could be reduced with overloading occurring only on a few occasions annually.

As a temporary alternative to immediate network reinforcement, DLR was introduced on one of the 44-kV overhead lines in combination with possibilities to ramp down wind power production in Rangeltorp. Monitoring and ramping could be done as a service from the Vattenfall control center, thereby the connection of Rangeltorp would not affect the existing plans for larger future reinforcements in the area.

The owners of the Rangeltorp wind farm and Vattenfall entered into a supply agreement whereby a DLR measurement system would be installed on the 44-kV overhead line network. Under the terms of this agreement, Vattenfall installed a wind power control system and is allowed to ramp down production of the Rangeltorp wind farm to reduce potential overloading of the 44-kV overhead line network.

DLR Measurement System

Vattenfall developed a list of the most important features it required in a DLR measurement system:

• Line sensors should be suitable for installing on the existing 44-kV overhead line.

• Hot-stick live-line installation should be possible.

• Weather parameters should be measured.

• DLR calculations should be included.

• Measured and calculated values should be transferred to and made visible in Vattenfall’s supervisory control and data acquisition (SCADA) system in the control center.

• Communications from the measurement site to SCADA system should comply with Vattenfall’s security demands.

After a market survey and performance evaluation, Vattenfall determined the Power Donut2 DLR system from Underground Systems Inc. would best fulfill its requirements. Internal criteria for the measurement location were as follows:

• The location should be as close to the overhead line’s hot spot as possible, well sheltered from wind but directly under the sun.

• The location should be discreet to prevent damages.

• The location should allow for communications and a low-voltage connection to be established, within reasonable cost.

• The location should be expedient from transportation and installation viewpoints.

After surveying the line, the best site was considered to be in a span just outside the feeding 145/44-kV substation. The Power Donut2 line sensor was mounted on the line, and the weather station and system ground station were placed on a separate pole beside it.

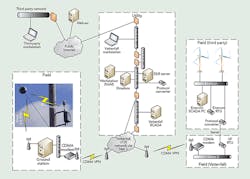

The measured values taken from the DLR site included wind speed and direction, ambient temperature, solar radiation, line temperature, line current and line inclination. All measured and calculated values are in the control center.

Wind Power Control System

Wind power ramping at Rangeltorp should be performed manually from the control center on the DLR-based capacity values as an open-loop regulation circuit. This implies no special construction is needed in the wind turbines, except for communications. For secure communications, the wind turbine supplier, Enercon, came up with a solution where a separate, protocol-converting remote terminal unit (RTU)-A was installed between Vattenfall’s and Enercon’s equipment. The measurement values from the wind turbines are transferred to the SCADA system: the total active and reactive power production (MW per MWAR), wind speed, wind direction and number of active turbines.

Control Center Integration

Wind power ramping as a tool for reducing overloads is a new activity in the network control center; hence, additional requirements arose from the local control center as follows:

• No separate stand-alone systems are accepted for DLR monitoring and wind power production control. Performance is referred to the existing SCADA system.

• All control center operators must be trained and able to handle DLR monitoring and wind power control.

• Information performance, alarm handling and documentation must follow normal standards in the control center. New routines must be well documented.

• A SCADA-supported decision tool must be developed.

A challenge for the strategy was to handle rapid variations of wind power production and to determine when ramping up and ramping down production should take place. Amplitude dead bands must be implemented.

Another problem anticipated was the ability to ramp up production without any unnecessary delays, which could be a problem in busy work situations in the control center, to avoid loss of revenues for the producer. A function that ramps up production automatically after a fixed time was implemented. Ramping down production also is shown in the event log with given alarms. The supply agreement with the wind farm power producer also makes provision for a follow-up report to be prepared and delivered after every ramping event.

Decision Tool and Presentation

The decision tool in SCADA is based on information from the DLR system and Rangeltorp wind turbines. Two separate values indicate an overload: the margin value and the line temperature. Margin value is a calculated value implying the remaining DLR-based capacity on an overhead line. A margin value of zero or negative indicates the overhead line is overloaded. Line temperature above 50°C (122°F) also indicates the overhead line is overloaded based on the profile and maximum permissible conductor sag.

To activate ramping, a separate wind power production control menu is used. The menu supports two different ramping alternatives: a predefined set point (always ramping to 20% of full production) and a manually defined set point (where a margin-based calculated value is presented as the default). If any of the two alarms occurs, control center operators are instructed to check the conditions on the 44-kV overhead line network to confirm the overload is really the result of a high level of wind power production. Wind power ramping is a useful tool to reduce the overload.

Experience to Date

The DLR measurement system has been in operation now for a year, providing the opportunity to observe the behavior of DLR and its variations with the local weather conditions. The level of static rating has been reached a few times and, during these occasions, a relatively big difference between the static and dynamic ratings was shown, related to the wind cooling effect. A difference of 180% was noted during one short period.

The system for wind power production control has not been used in operation yet, but an agreement in place with the wind power owner allows a functional test to be conducted three times a year to guarantee system functionality and check routines in the control center. The DLR system also creates opportunities for future data analysis, which should be used to learn more about DLR and local weather behavior.

Further Applications

The concept of DLR in combination with wind power control offers a more efficient use of the network’s capacity. In the pilot project, technical solutions were surveyed and tested, and control center routines developed. Vattenfall Distribution Nordic believes this method can be applied as a precautionary measure in several places on its distribution network, where wind farm connections can cause capacity bottlenecks.

Arne Bergström ([email protected]) is an operations analyzer at Vattenfall Distribution Nordic in Trollhãttan, Sweden, and manager of Vattenfall’s dynamic line rating pilot project. Bergström has extensive experience in power system analysis, from a long-term planning perspective as well as in real-time operations. He received a MSEE degree from Chalmers University of Technology in Gothenburg, Sweden, in 1983.

Urban Axelsson ([email protected]) has been with Vattenfall Research and Development, Power Technology since 1987, mainly engaged in HVDC and wind power projects. Within the wind R&D area, Axelsson is coordinating grid-connection and grid-integration studies, and he is presently engaged in alternative transmission solutions, such as low-frequency alternating current for grid connection of large offshore wind farms. Previously, he was manager of Vattenfall’s dynamic line rating R&D project. He earned a master’s degree in technical physics from the University of Technology in Uppsala, Sweden, in 1978.

Viktoria Neimane ([email protected]) is manager of grid technology for subtransmission networks with Vattenfall Distribution Nordic. From 2002 and 2013, Neimane was with Vattenfall Research and Development, working in several fields, including distribution networks and the integration of renewables. Since 2008, she also has managed a group of development engineers. Neimane earned a master’s degree from Riga Technical University in 1985 and a Ph.D. from the Royal Institute of Technology in Stockholm, Sweden, in 2001.

Mentioned in the article:

Enercon | www.enercon.com

Underground Systems | www.usi-power.com

Vattenfall | http://corporate.vattenfall.com