Digitization and automation have been focus areas for the Indian power grid over the last decade. During this period, the Power Grid Corp. of India Ltd. (POWERGRID), the central transmission utility for India, deployed IEC 61850-based grid substation automation in more than 100 substations across the country. The IEC standard defines a common communication protocol among intelligent electronic devices (IEDs) produced by different manufacturers to achieve extensive interoperability when installed on transmission system protection and control schemes. However, IEC 61850 is not just a protocol; it has changed how power systems are controlled, protected and monitored.

POWERGRID’s initial deployment of IEC 61850-based systems focused on the peer-to-peer communication link, namely, generic object-oriented substation events (GOOSE). GOOSE protocol uses a publisher/subscriber type communication, where event messages are sent by a device that other devices can be subscribed to receive. To start with, binary information was exchanged between IEDs for less critical applications, like the interlocking of substation switchgear, for example. The utility focused on less critical applications first to address any reliability concerns early. During this phase, the devices for digitizing analog information into IEC 61850 sampled values, the so-called “merging units” as they are called in the standard, were under development.

By 2013, the utility had selected process bus technology as a suitable option to overcome deficiencies of point-to-point copper connections between process-level equipment and IEDs as well as to harness the digitization of data at the process level for advanced diagnosis and maintenance planning. This launched POWERGRID’s journey into reimagining a future with fully digitalized substations.

Pilot Project

POWERGRID commissioned a pilot project in 2014 using process bus technology at its 400/220-kV Bhiwadi substation in the state of Haryana. The substation is equipped with three 315-MVA, 400/220-kV transformers; 10 400-kV feeders; and eight 220-kV feeders. For the pilot project, a process bus was installed on a 400-kV ac overhead transmission line, the Bhiwadi-Hissar No. 1 circuit. All the primary equipment associated with this circuit was digitalized in the substation switchyard using IEC 61850 process bus technology.

The process-level devices, designed for the digitization of data from the primary equipment level, were installed close to the primary equipment in the substation’s switchyard. Engineers specially designed the IEDs used for this project to withstand a harsh environment.

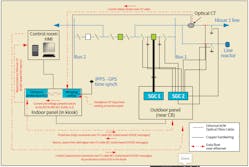

Two IEDs, or switchgear controllers, were installed in the switchyard on an outdoor panel close to the circuit breaker marshalling box. All the hard wiring from the circuit breaker, isolators and earth switches were terminated at the outdoor panel on which the switchgear controllers were mounted. Fiber-optic cables were used to connect the outdoor panel and optical current transformer installed in the overhead line terminal bay, from the switchyard to the kiosk housing the protection panel.

The merging units designed for the digitization of analog information from the current and voltage transformers into sampled value streams, conforming to the IEC 61850 9-2 Light Edition (LE) standard, also were mounted on the indoor panel in the kiosk. Similarly, the distance-protection IED installed to process the sampled values for various protection functions has an IEC 61850 9-2 interface to accept current and voltage transformer data instead of the conventional hardware installed in the kiosk. This IED was installed to process the sampled values for various protection functions.

Improving on the Pilot

POWERGRID used the pilot project at the Bhiwadi substation as a test bed for conducting performance evaluation studies on the network and devices, including examining the conformance of these devices to the IEC 61850 standard. The evaluation studies helped with refining specifications for the devices and factory acceptance testing (FAT) requirements by defining the specific test requirements for GOOSE and sampled values based on the protection schemes.

The issues identified were discussed in forums, called TISSUES, where technical challenges related to IEC 61850 were collected, logged, presented and resolved. Following a series of discussions with various IED manufacturers, POWERGRID was confident its updated requirements, stemming from what it learned during the pilot project, could be met. POWERGRID hopes its experience will help to ease some of the apprehension other utilities may have as they begin to adopt IEC 61850.

First Digital Substation

Since the pilot project at Bhiwadi substation began, diagnosing issues on the upgraded circuit has been more accurate. Furthermore, the process bus technology has enabled the online testing of protection and control schemes on this circuit without a shutdown. Formerly, a shutdown was required for these procedures, which in turn had an adverse impact on the availability of the grid.

POWERGRID leveraged the results of the performance evaluation studies to support India’s first full-scale commercial implementation of a digital substation at the 400-kV level. This project entailed retrofitting the control and protection system of an existing 400/220-kV substation located in Malerkotla in the state of Punjab. The substation was equipped to meet the IEC 61850 standard using a process bus-based substation automation system (SAS).

When commissioned in 1992, the 400/220-kV Malerkotla substation had a conventional protection and control scheme that required the extensive use of underground copper cables. The pilot project involved the digitization of a substation single bay. However, the full digitization of a substation was more challenging and complex.

The complete substation upgrade required updating the protection and control systems, including the bus bar protection system, for the entire substation. IEC 61850 process bus technology had to be installed on all feeders in the air-insulated switchyard as follows:

- 400-kV Malerkotla-Dadri overhead transmission line

- 400-kV Malerkotla-Patiala overhead transmission line

- 400-kV Malerkotla-Ludhiana overhead transmission line

- 400/220-kV transformer No. 1

- 400/220-kV transformer No. 2

- 400/220-kV transformer No. 3

- 50-MVAR bus reactor.

POWERGRID incorporated advanced networking techniques, such as virtual local area networks (VLANs) and multicast filtering, for efficient network traffic management. As time synchronization was extremely stringent, the devices used were subject to rigorous validation testing.

The most complicated part of upgrading the substation was the substation-wide bus bar protection, as it required extensive engineering and a unique network interface. The most beneficial aspect of a fully digital substation is the ease in which online testing using simulation and test modes can be employed. These modes were explored and tested at length before formal documentation was completed for ongoing maintenance and training requirements.

The FAT of Malerkotla substation upgrade project was completed in April 2019 and the site commissioning activities are under progress . Similarly, another fully digitalized substation, the 220-kV Greenfield Chandigarh substation, is currently under construction. The FAT is complete and commissioning tests are currently underway.

Process Bus Advantages

POWERGRID is excited about the process bus technology and the significant benefits it provides:

- In both of the process bus technology-based projects, POWERGRID has extensively used the GOOSE messages and sampled values for critical protection applications, which has enabled online testing of the protection and control schemes. This was not possible in the conventional substations. The online testing significantly reduces the overall time for system maintenance troubleshooting and offers a paradigm shift in the utility’s approach to protection system maintenance.

- In both projects, there was a significant reduction in the use of copper cables and concrete. In the Malerkotla substation, this reduction was even more significant as the switchyard panel rooms were not required.

Research Facility

In anticipation of the broad adoption of this technology, a state-of-the-art laboratory dedicated to smart grid, protection and automation research has been established at POWERGRID’s research facility, the POWERGRID Advanced Research and Technology Centre. Equipped with IEDs and configuration tools from different manufacturers, the laboratory is used for conformance testing of software and advanced network switches complying with the latest fast and secure protocols, which are used in the on-site studies that prove a simulation environment for various scenarios. The laboratory has undertaken various interoperability studies with devices from several manufacturers, including conformance validation with standards before on-site deployment.

Going Digital

The implementation of full digital substations offers advanced system diagnostics, smooth online system testing, resource optimization, and reduced troubleshooting and commissioning time. With this venture into the state-of-the-art IEC 61850 systems based on digital substation technology, POWERGRID is now in a position to incorporate even more digital and communication technologies into its substations.

Acknowledgment

The authors wish to acknowledge the following POWERGRID executives who have played a vital role in the implementation of the pilot project and digital substation installations: Umesh Sen, Yashwant Kodali, Ritesh Kumar and Arnab Ghosh.