In the early days of electric railways, DC was the most common power supply. As it was at the time not feasible to step down DC voltages on-board the train, transmission between the substation and the train had to be at a low voltage (between 750 V and 3,000 V) so that it could be fed directly to the traction motors. The disadvantage of the low voltage was that it caused high conduction losses in the overhead line.

Later, single-phase AC electrification using higher voltages was introduced (15 kV / 16.7 Hz and 25 kV / 50 Hz), reducing transmission losses. The penalty, however, was the large and heavy transformers that had to be carried on the train. For historical reasons, railways today use a multitude of different electrification systems, often based on what was state-of-the-art when electrification first began in a particular country or area ➔ 1.

1 The railway electrification systems of Europe

On traditional trains pulled by locomotives, the heavy transformer is not necessarily a disadvantage as it contributes to adhesion: The maximum force that the locomotive can apply to pull a train without losing adhesion on the rails is limited by the weight of the locomotive. In modern passenger trains, however, there is a tendency toward multiple-unit trains where the traction equipment is not concentrated in the locomotive but distributed along the length of the train in the same vehicles in which passengers travel. With the increased number of powered axles, adhesion is no longer a limiting factor for the train's acceleration, but the weight and size of the transformer remain a major constraint for train designers.

An ideal train would thus combine the low weight and small equipment footprint of DC trains with the low transmission losses of high-voltage AC electrification. Essentially, the challenge lies in making the transformer lighter. Unfortunately, the basic size and weight of a transformer are limited by the laws of physics. Factors determining the minimum size of a transformer include the frequency and the power rating – lower frequencies require larger transformers. A higher frequency transformer would permit weight savings as well as space savings. This is the motivation behind ABB's power-electronic traction transformer (PETT).

Principle of the PETT

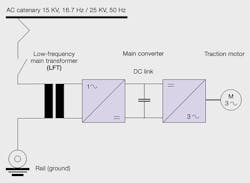

The power conversion path found in most modern AC trains is shown in ➔ 2. Current from the AC catenary (overhead line) flows through the primary windings of a low-frequency transformer (LFT) to the rail (which provides the return path). The reduced voltage available at the secondary windings of the transformer is fed into a four-quadrant line chopper converting it to DC-link voltage. An inverter converts this to variable-frequency and variable-voltage AC for the traction motors. Auxiliary supplies can also be fed from the DC link.

2 Conversion path in a modern AC train

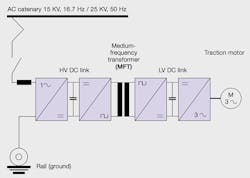

To use a medium-frequency transformer (MFT), a frequency converter must be placed before the transformer as shown in ➔ 3. On the secondary side of the transformer, a rectifier converts this to the DC link voltage.

3 Conversion path using a medium-frequency transformer

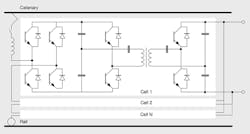

One major challenge of this topology is that a converter must be located on the high-voltage side. With the present generation of semiconductor devices not being able to block the voltages used in AC railway electrification, a series connection is required. Rather than a mass series connection of semiconductors into single valves, the solution developed by ABB features a series cascade of converter modules on the high-voltage side, with the outputs connected in parallel on the DC side ➔ 4. This topology makes the solution scalable and provides scope for redundancy (the "M out of N" system).

4 PETT with series cascade of converter modules on the primary side and outputs connected in parallel on the secondary side

The incoming AC from the catenary passes through a filter inductor before entering the first converter module. Each module of the converter consists of an active front end (AFE) block and a DC/DC converter block ➔ 5. The AFE block is essentially an H-bridge that regulates the charging of link capacitors. This topology also allows for active power factor control.

5 Every module consists of an active front end (AFE) block and a DC/DC converter block.

Cascaded converters

A further advantage of the cascade topology lies in the possibility of switching every module independently. This permits the switching patterns of the H-bridges to be interleaved.

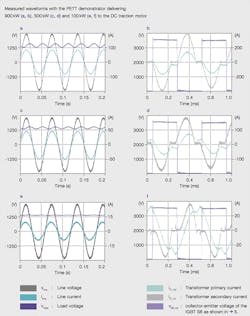

If they are interleaved evenly (ie, offset by 360 degrees/N, where N is the number of levels), the grid side of the converter sees an apparent (equivalent) switching frequency that is 2 N times higher than the actual switching frequencies of the individual H-bridges. This high apparent switching frequency (combined with the larger number of intermediate voltage levels) leads to a lower harmonic distortion than is possible with conventional traction converters, and hence reduces the need for input filtering. Sample waveforms are shown in ➔ 6.

6 Measured PETT waveforms

Medium-frequency transformers

Medium-frequency transformers play three key roles. To start with, they provide galvanic isolation between the high voltage coming from the AC grid and the low voltage connecting the load. Their second key function is to provide suitable voltage adaptation for the 1.5 kV DC load voltage considering the 3.6 kV intermediate DC-link voltage level. The third key functionality is to help the IGBT (insulated-gate bipolar transistor) modules in the LLC resonant circuits to work in the soft switching mode (described later). As overall size reduction increases the challenge from the dielectric point of view. This aspect has to be studied carefully.

In the present PETT demonstrator, all nine transformers share the same oil-filled tank, as does the line inductor and the start-up charger ➔ 7.

7 The transformer tank and its medium-frequency transformer

LLC switching mode

Each of the nine medium frequency transformers is a part of the associated DC/DC converter ➔ 4. By using the transformer's leakage and magnetizing inductances and the external circuit's capacitors, a resonant LLC circuit is created (Lr, Lm and Cr as shown in ➔ 5). The advantages of an LLC circuit include:

- Wide output-regulation range

- Reduction of switching losses on the primary side through zero voltage switching (ZVS) over the entire load range

- Low turnoff current controlled by the design (not truly zero current switching, ZCS)

- Low-voltage stress and ZCS on the secondary side diode rectifier

- Load-independent operation at resonant frequency

As an LLC circuit is based on the principle of resonance, variation of the switching frequency can be used to control the output voltage. However, in the present PETT implementation, this feature has not been used and the LLC resonant DC/ DC converter operates in the open loop with a fixed switching frequency of 1.75 kHz, which is below the resonant frequency.

The control system

The control targets can be summarized as:

- Maintaining sinusoidal input current

- Near-unity power factor

- Constant average DC-link voltage

- Grid harmonic rejection

The hardware is ABB's AC 800PEC controller, a platform that permits the integration of fast and slow control functions.

The PETT demonstrator on the SBB Ee 933 locomotive

Thanks to a long-term partnership between SBB (Swiss Federal Railways) and ABB, a pilot PETT installation is currently being tested on a type Ee 933 shunting locomotive (➔ title picture). In early 2008, ABB initiated extensive research and engineering work on all subsystems. The PETT demonstrator development came to fruition in spring 2011 and subsequently underwent full electric testing in the laboratory before the pilot was taken into operation.

The existing Ee 933 traction transformer and GTO rectifier were removed to provide space for the new PETT cubicle. Some mechanical adaptations and electronic interface rework was necessary to accommodate the PETT.

The locomotive operates under the 15 kV/16.7 Hz railway grid. The pilot installation was completed in mid-2011, and homologation with the Swiss Federal Office for Transport (FOT) was achieved by the end of the year. The locomotive commenced shunting operation in February 2012 at the Geneva Cornavin station.

The PETT ➔ 8 has nine cascaded modules, of which only eight are essential for operations (the ninth is for redundancy). The unit has 1.2 MW nominal power and can supply 1.8 MW peak for short durations. The DC output voltage is 1.5 kV. The overall weight is 4,500 kg, including cooling. When comparing this with traction transformers of the same power rating, it should be noted that the PETT not only replaces the actual transformer but also the LV rectifier (compare ➔ 2 and ➔ 3).

8 The complete PETT

The main aim of this pilot is to study the feasibility of this technology. Weight optimization was an additional consideration. The power density (expressed in kVA/kg) of today's transformer and rectifier combinations is in the range of 0.2 to 0.35. The generation of future PETT under development will exceed this by a considerable margin, achieving values of 0.5 to 0.75.

Further advantages include:

- Improved energy efficiency from AC input to DC output from 88 to 90 percent to more than 95 percent (today's average efficiency of 15 kV / 16.7 Hz standalone Traction transformer is in the range of 90 to 92 percent)

- Reduced EMC and harmonics

- Lower acoustic emissions

All these factors make the PETT ideal for its stated goal of providing a small, lightweight but powerful converter solution that can be accommodated on the trains of tomorrow, and that is suited for operation in close proximity to passengers.

The transformer of tomorrow?

As most other types of large transformer, tend to be stationary, traction is probably the application that stands to benefit most from reducing the transformer's weight, and hence the area where this innovation must occur first.

Although the PETT in this article is installed in a shunting locomotive, its real area of potential lies in multiple-unit trains for passenger service, such as commuter or high-speed trains. The PETT's compact size means it can easily be fitted under the floor of the train or on the roof, maximizing space available for passengers while reducing the train's power consumption.

Max Claessens

ABB Power Products, Transformers

Zurich, Switzerland

[email protected]

Dražen Dujic

Francisco Canales

ABB Corporate Research

Baden-Daettwil, Switzerland

[email protected]

[email protected]

Juergen K. Steinke

ABB Power Electronics

Turgi, Switzerland

[email protected]

Philippe Stefanutti

Christian Vetterli

ABB Sécheron

SA Geneva, Switzerland

[email protected]

[email protected]