Why Gas-Insulated Switchgear (GIS) Substations Are Key to Meeting Accelerating U.S. Power Demand

Nearly every forecast for U.S. power demand indicates a significant acceleration due to well-documented trends, ranging from electrification of the transport sector to construction of power-hungry data centers.

These trends are driving the need for rapid expansion of the electrical power grid. As utilities formulate strategies to move quickly to meet that demand, the speed-to-market advantages of gas-insulated switchgear (GIS) substations are worth considering.

Traditional substations built by utilities across the country are known as air-insulated switchgear (AIS) substations, where atmospheric air serves as the dielectric or electrical insulating medium, protecting equipment against the risk of damage from arc-flash events. Alternatively, a GIS substation commonly uses sulfur hexafluoride (SF6) gas as the dielectric medium inside pressurized, tightly sealed enclosures surrounding high- and medium-voltage equipment.

Due to several efficiencies in the respective project development and execution phases, GIS substations can be energized much faster than AIS substations while delivering numerous additional benefits.

Contrasts in Development Schedules

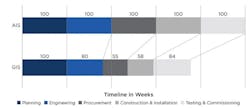

The time required for planning can be expected to be roughly equivalent for both GIS and AIS substations. However, the design time for GIS substations may be incrementally shorter due primarily to the modular, plug-and-play components needed for these facilities.

Procurement, construction, testing and commissioning are the stages at which schedules begin to significantly diverge.

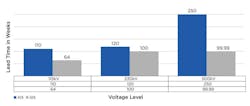

Supply chain bottlenecks that began during the COVID-19 pandemic have not abated, and there are continuing challenges in the U.S. power market with timely delivery of high-voltage equipment like circuit breakers, switches, cable, bus and transformers needed for AIS configurations. The sheer amount of steel and other materials along with labor needed for manufacturing these large, critical components are key factors contributing to lengthy order backlogs. Recent surveys confirm that lead times for procurement of GIS equipment are 45% faster than procurement of high-voltage AIS equipment.

Site Development Impact on Schedules

Acquiring the acreage needed for the AIS sites is another factor that can add time, complexity and cost to the project development process. AIS substations require a much larger site footprint, not only due to the size of the equipment but also because of the space required for access to perform regular operations and maintenance activities.

Further, it is difficult in the era we live in today to find a parcel of land without some environmental constraints present. Once parcels are obtained, extensive surveying and testing is often required, followed by extensive mitigation if any contaminants are found. Additionally, vegetation must be cleared and site leveling may also be required.

Meanwhile, sites required for GIS substations are typically much more compact. GIS substations are about 60% to 75% smaller in footprint compared to AIS substations. The time required for site development of a GIS substation is thus drastically reduced.

Impact on Construction/Installation Schedules

The compact configurations of GIS substations allow components to be delivered in modules and installed at a faster pace than traditional AIS equipment. Off-site GIS modular designs have shown they result in significant gains of up to 42% in construction and installation schedules.

In recent years, AIS projects have also come up with preconstructed modules that have helped reduce construction time frames. However, GIS designs offer the additional benefit of flexibility for delivery to compact sites such as refineries, urban areas, nuclear and manufacturing facilities. There are many documented instances in which the time required for assembly and installation was cut in half due to off-site preassembly of GIS components. While high-voltage air-insulated substations require larger footprints, transporting preassembled modules is limited by the shipping splits and transportation facilities.

Impact of Improved Testing and Commissioning on Schedules

The GIS units, in contrast to the preassembled AIS equipment, are fully assembled and tested at a factory or an off-site facility. This results in critical schedule reductions at the tail end of the project. In addition, the risk of unexpected issues is reduced during the testing and commissioning phase because site contractors have fewer items to test and troubleshoot on-site.

Over the life cycle of a substation project, there is an approximate 16% gain in the schedule when opting for GIS design over AIS for a typical substation project.

Added Benefits of GIS

GIS substations offer several additional benefits beyond faster project execution:

Longer life expectancy. Because GIS equipment is enclosed in gas and then installed within enclosed structures like those with metallic or concrete roofs, they are not exposed to lightning strikes or other potential damage from external elements. Some studies show that GIS equipment life cycles may range up to 50 years, compared with 25 to 30 years for the same equipment installed in air-insulated substations.

Operations and maintenance (O&M). The advent of modern technology, advanced controls and communication systems are standard with GIS substations. The use of modern technology such as digital twins and equipment predictive maintenance systems helps reduce the amount of O&M activity while providing greater access to the equipment. In addition, typical maintenance cycles for GIS equipment is eight to 10 years compared to five to seven years for AIS.

Physical security. With GIS substations located in enclosed structures with robust security features installed, risks of vandalism from intruders are greatly reduced. Though protective measures may be installed at air-insulated substations to mitigate risks of attacks, exposures are higher at AIS substations, compared to risks at GIS stations due to better physical barriers.

Flexibility for expansion. The modular components of a GIS substation can easily be installed in multistory configurations. If more capacity is needed due to load growth, an additional story can be constructed — a vertical expansion concept, versus the horizontal expansion that would be required for an air-insulated substation.

Levelized Long-Term Costs

Though the GIS equipment may represent higher up-front capital costs due to the need for sealed gas-insulated equipment, longer life cycles and faster construction schedules and in-service dates work to level the playing field.

With today’s high demand for a flexible grid able to deliver more power to evolving loads, the relatively fast turnarounds for construction of GIS substations are a positive factor that many utilities are now weighing carefully.

About the Author

Chiranjeevi Bala Kotharu

Bala Kotharu is a senior Electrical Engineer at Burns & McDonnell with over 10 years’ experience in Transmission and Distribution Consulting in US. An active thought leader and member of IEEE PES for over 15 years and a contributing member of IEEE substation Committees for grounding, lighting, Gas Insulated Substations and Resiliency.

Bala has a bachelor’s in electrical engineering from JNTU India and Masters in Power and Energy Engineering from University of Massachusetts.

William A. Munn

William A. Munn is a Chief Engineer at Southern Company with over 21 years of experience. He previously held positions as Principal Engineer, Engineer at Power South Energy Cooperative and Aircraft Electrician in the US Navy. Willaim is an active member of IEEE PES Substation Committees.

William A. Munn has a Master of Engineering (M.Eng.) in Power Systems from the University of Arkansas. He also has a Bachelor of Science (BS) in Electrical Engineering from Auburn University. Additionally, he has an Associate of Science (AS) in Pre-Engineering from Darton College.