Although converter transformers are critical to every high-voltage direct-current (HVDC) scheme, the limited number of original equipment manufacturers (OEMs) and the high industry demand means it can take more than four years to procure a replacement. Moreover, the tendering, evaluation and negotiation process can delay the procurement schedule by an additional eight months. With other constraints related to meeting the technical requirements of an existing station, brownfield unit costs can exceed, in many instances, that of new installations — with the average per unit cost ranging from CAD$6 million to $10 million.

To mitigate supply risk, shorten delivery time and reduce costs, Manitoba Hydro worked collaboratively with OEMs to develop and implement long-term alliance agreements for supply of its converter transformers.

Existing HVDC System

Manitoba Hydro is a vertically integrated Canadian government-owned corporation. It supplies a winter peak load of approximately 4200 MW and has an installed generating capacity of about 5700 MW, primarily hydroelectric power. More than 70% of the utility’s generated capacity is transferred over the Nelson River HVDC system, which is comprised of two transmission lines — Bipole I and Bipole II — rated at 1854 MW at 463.5 kVDC and 2000 MW at 500 kVDC, respectively.

Located in the electrically isolated Northern Collector system, three generating stations — Kettle, Long Spruce and Limestone — transmit power over the HVDC system to southern Manitoba. Surplus power is exported primarily to the United States, mainly by three 230-kV and one 500-kV export transmission lines. A converter transformer outage can severely limit the ability to transmit power generated in the North. Consequently, reliable operation of Manitoba Hydro’s converter transformers is of paramount importance not only to the utility’s ratepayers but also its export customers.

Manitoba Hydro’s HVDC division is part of the transmission business unit and assumes responsibility for all matters related to planning, designing, specifying, negotiating, acquiring, upgrading, expanding, operating and maintaining the corporation’s HVDC converter station assets, as well as planning and executing the divisional capital projects portfolio.

Existing Converter Transformers

Initially, it was decided to limit the scope of the alliance agreements to the Bipole I transformer for the following reasons:

• Bipole I would remain important once Bipole III was in service.

• Bipole I transformers are older.

• The Bipole II thyristor valve replacement plan is still being reviewed and transformer technical parameters are part of that review.

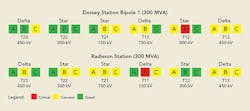

The Bipole I transmission line and its associated converter stations first transmitted power in 1972 and include 36 in-service single-phase transformers, half of which are located at the Dorsey converter station, 25 km (15.5 miles) northwest of Winnipeg and the other half at Radisson, near Gillam, Manitoba, 740 km (460 miles) north of Winnipeg. The system is divided into six valve groups of three operational voltages,

approximately 450 kVDC, 300 kVDC and 150 kVDC. Each valve group has its own group of three transformers, designated by the winding connection (star or delta) and its operating voltage. Each site has six delta-connected units operating at 450 kVDC, six star-connected units at 300 kVDC, and three star-connected and three delta-connected units at 150 kVDC.

The delta- and star-connected units of higher-voltage ratings can operate in the lower-voltage-rated valve groups of the same connection type. This was not true of the original transformers, but spares have been specified this way to minimize inventory and cost. Two emergency spare units of each transformer type also are located at Dorsey and two at Radisson to ensure prompt on-site replacement, should a failure occur.

Manitoba Hydro currently has 24 HVDC converter transformers that may need to be replaced over the course of the next decade. They have been operating at high load levels for up to 44 years. A failure of one Bipole 1 converter transformer could reduce the HVDC transmission capacity by up to 309 MW for two weeks if an on-site spare was available or more than four years if a spare was not available. Of the 36 original units on Bipole I, seven have been replaced at Dorsey and five at Radisson.

Manitoba Hydro regularly performs condition assessments of in-service units. A green assessment indicates a good operating condition, yellow suggests the need for closer monitoring and red warns the unit may be in a critical condition and fail at any time. Based on established reliability criteria, a red condition assessment of more than one transformer of the same type may trigger the purchase of more than one spare for that type.

Previous Project Challenges

Converter transformers have strict technical specifications and complex design requirements to meet the technical demands of HVDC technology and lower the risk of costly in-service failures. In-service failures stemming from quality issues or noncompliant designs pose significant financial and system reliability risks. For this reason, Manitoba Hydro’s technical requirements document contained more than 100 pages, capturing more than 40 years of operational and engineering experience.

For purposes of standardization of spare parts and familiarity with equipment by site personnel in case of emergency repair, some components such as tap changers and bushings were specified in the utility’s technical requirements by manufacturer and part number. Gaskets, ladders and platforms to be used in the manufacturing process were also described in detail to ensure compliance. Furthermore, the technical requirements included mandatory testing of wiring connection samples and rubber gaskets by owner. The owner’s engineer was given significant authority to reject substandard or noncompliant drawings, samples and other components under this contract structure.

Although Manitoba Hydro’s technical requirements document was one of the most comprehensive converter transformer specifications on the market, the utility realized — based on previous experience — it may have caused too much deviation from normal practices for many manufacturers. It also was aware that this may have caused longer delivery time and price increases to both the purchaser and the supplier.

To capture the objective opinion of OEMs, Manitoba Hydro retained an external transformer consultant expert to meet with the suppliers. Based on their feedback, the utility learned the following specifications most significantly impacted the schedule and price:

• Connection and other sample requirements.

• Specific designs for raceways, control cubicles, platforms and staircases.

• Drawing review process.

A traditional tender, bid (negotiation) and award process of a converter transformer often can take up to eight months. The tendering process is expensive to both the owner, who must prepare the tender, and the supplier, who must estimate the costs and respond to the tender.

Repeatedly tendering the same design was expensive and resource intensive, and it supported the case for pre-negotiated commercial terms. If one design was completed by a supplier and that same unit type was later awarded to a different supplier — because of lower costs or lack of slot availability from the OEM — the parties would spend nearly six months going through the iterative design process, expending costs of approximately $500,000 (per design) excluding the price of internal engineering labor.

It was clear Manitoba Hydro needed to optimize, and perhaps reduce, the complexity of its specifications and produce a contract structure that would use existing models.

Developing Alliance Agreements

Based on the importance of converter transformers to the overall system, as well as the potential cost savings, Manitoba Hydro developed a business case and was given authority by the Manitoba Hydro-Electric Board to negotiate alliance agreements directly for the supply of converter transformers for up to seven years in duration, in value of up to existing budget level.

The first step was to ensure a common understanding of the expert consultant report with the OEMs. After numerous meetings, technical experts from both sides agreed on a number of mutually acceptable solutions using simplified designs and standardized parts. For instance, the parties agreed on supplier-proposed alternatives for specified parts the supplier could use, after demonstrating they would not adversely affect performance.

In previous contracts, design and manufacturing formed part of one purchase order, and they were awarded and paid for as a package. The new contract structure enabled the prepurchase and completion of a transformer design, with the ability to execute manufacturing later. Once a unit has been designed and approved by the owner, the parties will discuss manufacturing slot availability based on in-service unit condition assessments. This enabled Manitoba Hydro to be prepared for an eventual failure and reduce delivery time should a failure occur.

Former fixed-price contracts accounted for risks, including potential hikes in material and transportation costs, as well as increases in costs of any components specified and supplied by a third-party supplier. In turn, those risks were paid by the owner through higher prices. With the new structure, the OEM and the owner minimized the risk element, thereby reducing the price.

Initial pricing was pre-established based on four converter transformer types and escalated using a formula based on defined public material, currency exchange and labor indices. In picking the indices and defining the escalation formula, it was important to ensure the indices reflected actual costs of materials, were public and verifiable, and the weight assigned to each index was reflective of the material weight and transformer type. The final price formula was based on two components: fixed price for the design plus escalation based on labor and material indices.

For repeat designs, the design portion of the cost would be minimal since little additional engineering work would be necessary. The new pricing methodology also includes transportation priced on a cost-plus-fixed percentage basis, minimizing the associated risk costs.

The alliance agreements established operational, management and executive committees with representation from engineering, project management and purchasing from both sides to ensure successful project completion.

The Path Forward

By challenging its traditional procurement methodology, Manitoba Hydro expects to cut costs, mitigate supply risks and reduce delivery time of its critical converter transformers. The collaborative development of alliance agreements was beneficial to both parties by simplifying the design and manufacturing process while reducing the technical and commercial risks. Manitoba Hydro plans to continue to benefit from the use of alliance agreements and apply the lessons learned on future equipment procurement projects.

Petar Calic earned a BSEE degree from the University of Manitoba in 2007. Since then, he has been working in different areas of Manitoba Hydro and is currently section head of HVDC project support in HVDC engineering. He is a registered professional engineer in Manitoba, Canada, and a project management professional.

Philip Tan earned BSEE and MBA degrees from the University of Manitoba in 1973 and 1980, respectively. Since 1973, he has been working in various areas of Manitoba Hydro and is currently section head of HVDC projects in HVDC engineering. He is a registered professional engineer in Manitoba, Canada, and a member of the Project Management Institute.

Kelvin Kent earned BSEE and MENG degrees from the University of Manitoba in 1986 and 1994, respectively. Since 1986, he has been working at Manitoba Hydro and is currently the maintenance and performance section head in HVDC engineering. He is a registered professional engineer in engineer in Manitoba, Canada, and has been an IEEE senior member since 2001.