Island to Island: An Alaskan High-Voltage Submarine Cable Failure

When communities on remote islands are connected to an interconnected power system, the reliability of supply gets a boost while customer energy costs are reduced. For the small island of Petersburg, Alaska, U.S., the electrical connection to the Southeast Alaska Power Agency’s (SEAPA) power system reduces customer energy costs by more than 70%. Without SEAPA’s carbon-free connection, Petersburg would be forced to rely on diesel generation that, on average, discharges some 92,250 lb (41,844 kg) of CO2 annually.

In September 2019, one of SEAPA’s four, single-phase 138-kV oil-filled submarine cables failed. It was lying at a depth of 700 ft (213 m) at the bottom of the Stikine Strait crossing between the two uninhabited islands of Woronkofski and Vank. The potential cause of failure was an underwater avalanche-like landslide that separated the cable. Installed in 1984, these high-voltage (HV) subsea cables form part of SEAPA’s 175-mile (282-km) transmission system, which connects the communities of Petersburg, Wrangell and Ketchikan, Alaska, to the utility’s hydro-generation facilities.

SEAPA has four submarine cable crossings, each consisting of four single-phase cables totaling more than 55 miles (86 km). Three of the four cables in each crossing are energized continuously, with the fourth cable — a spare — deenergized at any given time. Every year, SEAPA rotates the energized cables to ensure their integrity, resulting in one cable remaining deenergized for no longer than one year at a time.

Following the energization of the previously deenergized (spare) cable, the three-phase power supply to Petersburg was restored, but with an elevated risk to the security of that supply. Failure of any of the remaining single-phase cables would result in Petersburg having to resort back to diesel generation, with an energy cost up to four times the average. To avoid this scenario, a project was initiated to repair or replace the faulted HV cable with minimal delay.

Fault Investigation

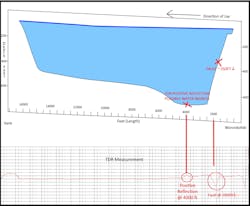

Before considering cable replacement, SEAPA investigated the possibility of performing a splice to effectively repair the failed cable. Time-domain reflectometer (TDR) tests were performed to identify the position of the fault. Test results signaled a negative reflection, indicating a break in the cable at nearly 2000 ft (610 m) offshore at a depth of 350 ft (107 m). A smaller positive reflection also was evident, which was either a possible ghost reflection or water ingress from gravity and density differentials between the seawater and oil.

Remotely operated vehicle (ROV) footage revealed the failed cable was severed and that water ingress was highly probable at the point of failure to the deepest part of the cable. Although SEAPA had 2000 feet of oil-filled cable in storage, when considering the probability of water ingress over a cable length greater than 2000 ft, the agency concluded it was not possible to repair the cable.

A Replacement Cable

Subsequently, specifications for a new replacement cable were developed, and SEAPA launched a request for proposals (RFP) with the support of a submarine cable consultant, Center Marine Services Inc. The replacement cable contract was awarded to Sumitomo Electric Industries Ltd. through a competitive evaluation bid process. SEAPA selected the company because of its reliable track record of more than 100 years of submarine cable manufacturing experience and sound proposal based on extensive knowledge of the U.S.

SEAPA engineering and eTrac Inc. gathered and provided an arsenal of information to Sumitomo:

- ROV footage.

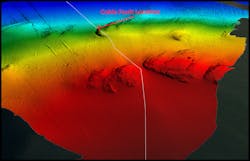

- High-resolution multi-beam sonar bathymetric maps.

- Magnetometer sub-bottom profiles.

- Directional peak cable location surveys.

- Using SEAPA-furnished surveys, Sumitomo began the design process for the replacement cable in November 2020.

Design Phase

The SEAPA transmission system for Petersburg was designed and installed with 138-kV submarine cables to supply a potential 200% increase in load growth. However, since its commissioning in 1984, this transmission system has remained in operation at 69 kV. Therefore, SEAPA specified a 69-kV cable instead of a 138-kV cable to reduce costs while still maintaining a sufficient 100% increase in load-transfer capacity for future growth. The decision to reduce the voltage requirement also reduced the following:

- Total cable weight

- Challenges associated with transportation logistics

- Time for cable installation

To satisfy SEAPA specifications, Sumitomo designed a double-armored 69 kV XLPE insulated submarine cable with integral fiber optics that would sustain a pressure of 315 psi at a water depth of 700 ft (213 m). A continuous 17,400-ft (5, 304-m) length of cable was manufactured with no factory splices. Ancillary equipment required to perform potential future repairs had to meet similar demanding pressure requirements.

Along with the new cable, Sumitomo designed a dual-purpose cable storage turntable system to transport the cable from Japan to Alaska and store the recovered existing oil-filled cable prior to installation of the new cable. The design included oil containment for potential escapement due to temperature-related pressure changes in the existing cable that had to be recovered from the subsea floor.

Cable Removal Phase

Sumitomo subcontracted the cable installation and cable removal phases of the contract to ITB Subsea Ltd. (ITBS). The 17,400-ft (5304-m) cable, weighing more than 600,000 lb (272,155 kg), was transported from Japan to Vancouver, British Columbia, Canada, where it was transferred to the ITBS dynamic-positioning vessel. On July 1, 2021, ITBS began the removal phase of the project.During the oil extraction process, and governed by fluid dynamics, oil extracted on the shoreline was replaced by saltwater at the fault location 350 ft (107 m) below the ocean surface. With 140 gal (530 liter) extracted, nearly 8000 ft (2438 m) of cable was oil free.

The cables were capped and hydraulically locked, ready for removal. With the cable ends capped, the process for removing the cable consisted of the following:

- Pulling the shoreline ends onto the vessel, the ITB 45, using ropes and mesh pull grips.

- Using dynamic positioning, the existing cable was extracted onto the ITB 45 and loaded into the cable storage system, specifically designed to contain the cable should an oil leak occur.

- Monitoring tensions so as not to exceed the cable manufacturer’s tension limits.

- Calculating fluid dynamics to determine the depth required to maintain equilibrium pressures for CanPac Marine Services Inc. divers to install caps without oil escapement.

- Deploying divers at the faulted cable ends to cap the cable underwater and prevent oil escapement.

- The cable removal phase proved to be successful, with no oil released and 100% of the faulted cable removed. The total start-to-finish time of four and a half days included diving operations, ROV cable location, shoreline extractions and dynamic positioning vessel subsea extractions.

Cable Installation Phase

Removal of the existing cable may have been the riskiest operation of the project, but installation of the new cable proved to be the most challenging. Southeast Alaska has tidal exchanges of more than 20 ft (6 m), with some of the most extreme riptides and tidal currents in the world. Located within the Alexander Archipelago, Vank and Woronkofski Islands have steep shorelines, no access roads and volcanic rigid rock formations under the water surface.

Precise routing plans with precision routing equipment was required for this phase of the project to be successful. Although it was preferred the cable be laid completely on the subsea floor, cable spans were allowed but had to be less than 20 ft in length, with the cable laid entirely within the existing permitted right-of-way. Rock outcrops, boulder fields, cliffs and steep slopes had to be avoided as well as sharp changes in the seabed profile.

Installation was planned to happen during the lowest tidal exchange in the month of July to minimize the effects of tidal currents while the cable was being laid at a depth of 700 ft (213 m) below the water surface. Coincidentally, this window of opportunity occurred on July 4, 2021. While the residents of Wrangell were enjoying Independence Day festivities, SEAPA, Sumitomo and subcontractors were diligently performing operations to successfully install the new submarine cable during the small window of low tidal exchange. The results of this installation phase were exactly as engineers planned.

Failure Turned Success

With little wind, bluebird sunny skies and minimal tidal currents, the new subsea cable was installed from shore to shore without incident. An underwater ROV was deployed during operations to confirm the approved cable route and specifications were met. The result was the 3.3-mile (5.3-km) subsea cable was installed with only two short sections suspended less than 6 inches (152 mm) above the seabed and spanning less than 15 ft.

Partial-discharge testing was used to confirm a successful installation project undertaken by Sumitomo, ITBS, Westpark Electric Ltd. and all the participating subcontractors. The collaborative efforts of all parties turned SEAPA’s Alaskan island-to-island subsea HV cable failure into an island-to-island success story.

Robert Siedman, P.E., graduated cum laude from Washington State University with a bachelor’s degree in electrical power engineering and joined the Schweitzer Engineering Laboratories Inc. He expanded his experience at the U.S. Army Corps of Engineers (USACE), where he held the position of chief of power systems for the USACE Hydroelectric Design Center. Following more than 15 years of power-related experience, Siedman joined the Southeast Alaska Power Agency (SEAPA) in 2017 and currently serves as director of engineering and technical services.

For More Information

CanPac Marine Services | https://canpacmarine.com

Center Marine Services Inc. | (360) 620-5720

eTrac Inc. | www.etracinc.com

ITBS | www.itbmarine.com/itbsubsea

Sumitomo Electric | https://sumitomoelectric.com

Westpark | www.westparkelectric.com

About the Author

Robert Siedman

Robert Siedman P.E. ([email protected]) is Director of Engineering & Technical Services at Southeast Alaska Power Agency. Robert graduated Cum Laude from Washington State University with a bachelor’s degree in electrical power engineering and joined the Schweitzer Engineering Laboratories Inc. He expanded his experience at the U.S. Army Corps of Engineers (USACE), where he held the position of chief of power systems for the USACE Hydroelectric Design Center. Following more than 15 years of power-related experience, Siedman joined the Southeast Alaska Power Agency (SEAPA) in 2017 and currently serves as director of engineering and technical services.