On-Line System Measures and Monitors Partial Discharge

The constant availability of medium- and high-voltage electrical assets used in the generation, transmission and distribution is important for a reliable power supply at both utilities and also industrial plants. Partial discharge (PD) is considered to be one of the major contributors to the degradation and failure of insulation systems in electrical assets.

Because PD activity is often present well in advance of insulation failure, asset managers can assess it over time and make informed strategic decisions regarding the timely repair or replacement of the equipment before an unexpected outage occurs. PD detection is therefore essential to ensure the reliable, long-term operation of electrical equipment.

Although users consider PD detection and monitoring as beneficial for trending insulation conditions in electrical assets, the system installation and data analysis were often too complicated and time-consuming for the average user. In addition, users wanted a system that is more flexible for short-term and long-term use on multiple assets, rather than investing in multiple systems. That is why OMICRON decided to develop a portable on-line PD measurement and monitoring system, which is easier to install and use on various assets in the field.

One system for various applications

OMICRON’s MONTESTO 200 combines on-line partial discharge (PD) measurement and temporary on-line PD monitoring functions into one portable system. The IP65 rated MONTESTO 200 can be used both indoors and outdoors for insulation condition assessments on various medium-voltage and high-voltage electrical assets under load, including motors and generators, power transformers and power cables. This versatility makes it possible for users to only invest in one system for assessing the insulation condition status of electrical assets throughout a utility or industrial plant.

Plug-and-play connections to various PD sensors

MONTESTO 200 is designed for use with a variety of PD measurement sensors from OMICRON and other suppliers, including coupling capacitors for rotating machines, bushing tap sensors and UHF drain-valve sensors for power transformers, as well as high-frequency current transformers (HFCTs) for power cables.

These PD measurement sensors can be permanently installed and connected to MONTESTO 200 via OMICRON’s Terminal Box, which is also permanently installed at the asset. This enables safe and convenient plug-and-play connections while the asset is on line to avoid unnecessary downtime during setup.

Easy on-site PD measurements

The lightweight and compact MONTESTO 200 comes with all the necessary connection cables in a wheeled case that is easy to transport to various locations for on-line PD measurements on site. The system’s wide measurement frequency range can be freely adjusted to ensure an optimal signal-to-noise ratio. PD measurement data streams can be recorded and replayed later for detailed analysis.

Remote monitoring setup and data access

For temporary PD monitoring, users can easily mount MONTESTO 200 to a surface on or near the asset, connect it to the Terminal Box, and then leave it unattended. PD monitoring sessions can be quickly set up in less than 10 clicks of a mouse. MONTESTO 200 features a built-in computer that enables long-term data collection and archival. Users can access this computer from any remote location to set up monitoring sessions and to view the collected PD data with the system’s convenient web interface. Users can also configure the system to automatically send email alarm notifications when PD levels exceed user-defined thresholds.

User-friendly software

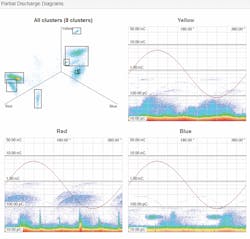

The MONTESTO 200 software simplifies system setup, PD data analysis and reporting. Unique software features, such as 3PARD (3-Phase Amplitude Relation Diagram) and Automatic Cluster Separation, automatically separate noise from PD signals to help users quickly and reliably determine the signal source. Data from third-party sensors can also be easily integrated for correlation with the PD data.

Various application areas

MONTESTO 200 is intended for use by asset manufacturers, maintenance teams at utilities and industrial sites, as well as service providers for convenient on-line PD measurements and temporary PD monitoring. The two-in-one solution can be used, for example, to clarify asset insulation issues during warranty periods; to periodically check insulation condition during an asset’s service life; to identify insulation issues that require immediate attention; to observe assets at risk over extended periods of time; and to plan maintenance and investment based on asset condition.

OMICRON has several years of experience in the field of PD measurement, monitoring and analysis on medium-voltage and high-voltage assets with customers in the asset manufacturing, power utility and industry sectors all over the world.