Key Highlights

- KEPCO S-CAP uses environmental and engineering data to suggest optimal protection measures, improving accuracy and reducing reliance on outdated practices.

- The software's validation through full-scale tests ensures reliable design standards, exceeding traditional tools like the Burial Protection Index (BPI).

- Implementation of S-CAP has led to significant cost savings—up to 50%—and enhanced environmental sustainability in submarine cable projects.

- Recognition by DNV underscores the scientific rigor and global applicability of KEPCO's protection standards, setting new industry benchmarks.

- The tool supports both HVDC and AC submarine cables, helping prevent damage, reduce repair costs, and ensure stable power supply to remote and vulnerable regions.

As the world is accelerating its push for climate change mitigation, energy transition and cross-border power interconnection, the demand for submarine cable construction — particularly for high-voltage direct-current (HVDC) transmission and offshore wind power — has increased sharply. These submarine cables serve as vital arteries in the modern grid, connecting offshore generators to onshore demand centers.

Recent incidents surrounding submarine cables in the Baltic Sea and Taiwan have highlighted not only the high cost of restoration, but also the critical importance of safeguarding the cables to maintain stable supply and prevent large-scale blackouts. As a result, reliable protection of submarine cables has become a core concern in the construction and operation of international power grids.

Submarine cable protection measures must account for numerous marine environmental factors, including the threat posed by anchors dropped and dragged by sailing and fishing ships, dynamic water depth and current conditions, wave energy and seabed composition. In softer seabed made of clay or sand, trenching and burial of cables has been the conventional method. However, in geologically challenging areas with hard rock or in deep waters where burial becomes impractical, alternatives such as rock berms and concrete ducts are applied.

Despite wide usage of these alternatives, standardized design criteria and protective engineering standards are lacking globally. The lack of criteria and standards leads to frequent reliance on empirical rules of thumb or outdated practices, which often results in overly conservative (and costly) designs or, conversely, inadequate protection that causes damage and repair that could have been avoided.

Technology Development

To overcome these challenges and drive innovation, Korea Electric Power Corp. (KEPCO) developed the KEPCO Submarine Cable Protector (KEPCO S-CAP), computer software that suggests scientifically quantified and optimized submarine cable protection options. The software incorporates a set of standards the utility developed to protect its submarine cables from the risks posed by complex marine environments and elevates cable protection from a reactive engineering measure to a proactive, data-driven design process.

The software provides optimal and multiple protection options when its users simply input key environmental and engineering variables — such as anchor types and weights, wave height, current velocity and seabed properties, including unit weight, undrained shear strength and internal friction angle. Once entered, the design program automatically calculates the optimal burial depth for each segment of the route, suggests options while recommending the most appropriate protection, generates cross-sectional drawings and outputs a comprehensive design report.

This streamlined and standardized process significantly enhances design accuracy, reduces subjectivity and improves documentation and traceability.

Full-Scale Validation

Determining an appropriate burial depth is one of the most critical and sensitive issues of submarine cable protection design. A widely used design tool in Europe, the Burial Protection Index (BPI) offers simplified burial depth guidance but has several limitations. It often relies on users’ interpretation and is not suitable for multilayer seabed profiles commonly found in offshore construction zones.

To address these deficiencies and build a robust engineering foundation, KEPCO conducted extensive numerical simulations and carried out full-scale validation tests at its Gochang Power Testing Center in Jeollabuk-do, Korea. Operated by KEPCO Research Institute (KEPRI) and spanning nearly 741,000 sq m (8 million sq ft). The site includes 765-kV transmission testing lines and underground cable verification facilities, enabling comprehensive trials under realistic field conditions.

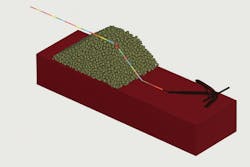

Based on these rigorous tests, KEPCO established a key design principle: The burial depth must exceed the sum of maximum anchor penetration and additional safety margin. This empirical finding was converted into engineering standards, and KEPCO developed formula-based design charts for estimating appropriate burial depth depending on anchor type and seabed conditions. Furthermore, in instances where burial alone was insufficient or infeasible — such as on exposed rocky seabed or in active fishing zones — the utility created quantified design standards for protective structures such as rock berms.

KEPCO S-CAP operates based on these standards that include specifications for berm dimensions, material selection and installation tolerances. The software applies variable burial depths based on localized marine risk, making it more effective and economical than legacy methods that mandate uniform burial depths, such as a flat 1.5-m (4.9-ft) minimum.

In a major implementation, KEPCO used the software for the Southwestern Offshore Wind-to-Land Connection project in Korea. This significant infrastructure project targets grid connection by 2029 and full completion by 2031. By implementing the software, KEPCO reduced its cable installation costs by an estimated rate of 50% — equivalent to approximately USD$3.6 million — while also minimizing environmental impact. Additionally, the digitized reporting format and transparency of design logic helped to enhance mutual trust between project owners and contractors.

International Recognition

KEPCO S-CAP represents a shift from convention- and experience-based engineering to a science- and evidence-based framework. This advancement was officially recognized in February 2024, when KEPCO received a letter of document verification from the globally respected classification and certification body, Det Norske Veritas (DNV) on its submarine cable protection design standards. This marked the first time a submarine cable protection method was formally verified for its scientific rigor, quantitative methodology and real-world applicability.

The software is now positioned to support global submarine cable projects across offshore wind farms, HVDC transmission corridors and interregional energy interconnection.

Preventing Damage

KEPCO S-CAP is applicable to both HVDC and alternating-current submarine cable construction and reinforcement projects. The software provides a scientific and quantifiable design method that ensures both safety and economic efficiency. In practical terms, it can reduce construction costs by approximately 5%, or about USD$2 million per 100 km (62 miles) of cable.

When a submarine cable fails, the repercussions can include massive blackouts and high repair costs. By preventing damage before it occurs, the design program enhances the structural integrity and durability of submarine cables, ensuring stable transmission of electricity to vulnerable or remote regions, including island communities, in a high-risk environment.

KEPCO S-CAP stands as more than just a technical tool — it is a holistic solution combining data-driven engineering, field-proven methodologies and globally recognized design principles.

About the Author

Jeonghun Kim

Dr. Jeonghun Kim is a Senior Researcher at the Korea Electric Power Research Institute (KEPRI). KEPRI is the R&D branch of KEPCO (Korea Electric Power Corporation), the state-owned electric utility of South Korea.