Poles Apart: The Surprising Truth About Power Pole Evaluation Methods and Their Results

What’s the best way to assess and maintain your utility’s pole assets? For many electric utilities, the decision has been guided without strong empirical data to back the choice of inspection process.

To provide the industry with more current insights, Osmose just completed a robust, comparative study of multiple combinations of pole inspection methods to recalibrate which approaches provide the most reliable results for the circumstances and budget available. The findings of the study suggest that it is time for utilities to reassess their approach to pole plant asset management programs.

Healthy utility poles are essential for delivering electricity and communication services to customers. While utility poles may look resilient above the surface, they are subjected to climatic and soil conditions that most often cause unseen decay below the groundline.

The key to efficiently managing the utility wood pole plant is the ability to correctly differentiate poles without decay from decayed poles that can stay in service (decayed but serviceable) and decayed poles that must be reinforced or replaced (reject poles) per the National Electrical Safety Code (NESC). Correct identification of a pole's condition into these categories reduces risk and allows the application of preservative treatments to mitigate decay and extend the asset's life.

In this study, the condition of each pole was evaluated after each additional method was added to the process including multiple types of partial excavation.

Industry Benchmarks

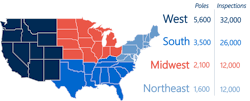

Beginning in February 2021, Osmose began an ambitious study to quantitatively measure the effectiveness of combinations of utility pole evaluation methods over the course of a two-year labor-intensive study across the United States. Over 13,000 poles were visited, with more than 80,000 different inspections performed, leading to the largest collection of effectiveness data for traditional inspection methods ever assembled.

The overall goal was to provide Osmose and the industry with reliable benchmarks for the effectiveness of different inspection processes to correctly identify groundline condition as:

- No decay

- Decayed but serviceable (DBS)

- A reject

The study was executed across four regions in the United States and included the two species types used for utility poles today, thick and thin sapwood. These species types have very different primary decay patterns:

- Thick sapwood species, primarily southern yellow pine, typically decay from the outside-in below ground.

- Thin sapwood species, Douglas fir, western red cedar, and lodge pole pine, typically decay from the inside-out below ground.

A single blind process was employed in the study:

- The first pass crew performed the bevy of combinations of inspection methods: visual assessment, sounding, boring, and 1-sided pull backs and partial excavations. In addition, 2-sided pull backs and partial excavations were performed for thick sapwood. Thin sapwood species also had a 1-sided deep partial excavation performed.

- The second crew performed the full excavate and treatment inspection process.

Each crew had no knowledge of the other’s results, preventing bias. The first pass trained inspector determined the no-decay, DBS, or reject condition for each pole at each additional step of the inspection processes (over 80,000 inspections). Using only the decay that could be detected and measured with each step, the crew utilized Osmose propriety software, StrengthCalc®, to estimate remaining strength.

Condition-Based and Non-Condition Based Programs

Some pole owners specify an inspection process to start with a combination of fewer inspection methods than the comprehensive full excavation process. However, if decay is detected or expected at any point of the original inspection methods, a condition-based program calls for the crew to continue inspecting to the full excavate process. If the specification does not require additional inspection after detecting or expecting decay, the trained inspector makes the pole condition call based only on the specified combination of methods, which is known as a non-condition-based program.

Osmose included both condition-based and non-condition-based results for partial programs in the study to understand the value of each program type.

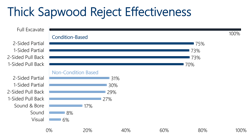

Inspection Effectiveness in Thick Sapwood Results

The thick sapwood reject effectiveness chart shows the percent of full excavate groundline rejects found by each inspection process, all of which identified over 500 reject poles. The thick sapwood pole species in these results include southern yellow pine and northern pine.

Since shell rot is the primary mode of decay and strength loss in thick sapwood species, the most important measure of determining decay presence is physical assessment of the below ground outside surface of the pole. This can be seen most pronounced in the difference between the condition-based and non-condition-based partial excavate programs. The condition-based partial excavate programs identified approximately 40% more groundline rejects than the non-condition-based partial excavate programs.

While the graph displays full excavate inspection effectiveness at 100%, that number was used as the baseline number of rejects for this study. It is unlikely that field performance will find 100% of groundline rejects due to various field conditions.

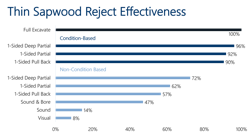

Inspection Effectiveness in Thin Sapwood Results

The thin sapwood reject effectiveness chart shows the percent of groundline rejects found by full excavate for each of the other inspection processes all of which identified over 250 reject poles. The thin sapwood pole species in these results include Douglas fir, western red cedar, and lodge pole pine.

Similar to the thick sapwood results, the condition-based partial excavate processes for thin sapwood species had an average reject effectiveness that was superior to the non-condition based inspections by a margin of 20% to 30%. However, in thin sapwood species, there is more differentiation between the non-condition-based partials, with the 1-sided deep partial being markedly superior to the 1-sided pullback.

This difference does not equally translate to the condition-based partial programs, which are all very similar in reject effectiveness. Additionally, the sound and bore process in thin sapwood species has a higher average reject effectiveness than in thick sapwood species, with the visual and sound processes still showing an average reject effectiveness of less than 20%.

Similar to thick sapwood, 100% effectiveness for thin sapwood is a baseline for the study, and it is unlikely that field performance will find 100% of groundline rejects due to various field conditions.

As utilities strive to bring the best value to their customers and their shareholders, finding the proper balance between the additional cost of increased rigor in the inspection process and the costs of missing rejects in a utility’s wood pole plant can feel like a guessing game.With this study, Osmose has provided an updated, quantified view of the differences in the effectiveness of various combinations of standard industry methods of utility pole inspection. This study recontextualizes the average groundline reject effectiveness for all inspection processes in thick and thin sapwood species using a research program never before conducted in the wood pole inspection industry. Osmose can now provide the realistic average reject effectiveness values for each process anywhere in the United States.

While the most effective inspection process available in any species is still a full excavate inspection, these results provide data-based comparisons to better understand the average reject effectiveness of any combination of other inspection methods. Additionally, by comparing these processes against the full excavate inspection, the gold standard of inspection in the utility industry, Osmose has created a benchmark that any future inspection method can be measured against.

Conversely, for thin sapwood poles, condition-based partials performed almost as well as the full excavate inspection in finding groundline rejects, with the non-condition-based partials and sound and bore processes providing some lower level of performance.

Robert Batchelor ( [email protected]) is the Associate Product Manager – Pole Inspection and Treatment at Osmose. He holds a BS in Chemistry from Armstrong University. He is an active member of AWPA and ASC 05, which provides standards and dimensions for wood poles. In his current role, he oversees the design, development, and implementation of Osmose’s industry-leading wood pole inspection and treatment products and services.

Nelson Bingel ([email protected] ) has over 35 years of industry experience focused on structural and electrical aspects of overhead lines. He received a BSME from Purdue University and has completed research and development to improve structure inspection processes and restoration systems along with software for field strength and loading evaluation. Nelson has been a member to the National Electrical Safety Code (NESC) for 32 years where he has served as Chairman of the Strength and Loading Subcommittee, Chairman of the full NESC committee from 2016 until March 2023, and is currently the immediate past Chairman. Nelson is also Vice Chairman of the Accredited Standards Committee O5 which develops standards for new wood poles and crossarms. While active on the NESC, Nelson also worked at Osmose for over 30 years.

About the Author

Nelson Bingel

Nelson Bingel has over 35 years of industry experience focused on structural and electrical aspects of overhead lines. He received a BSME from Purdue University and has completed research and development to improve structure inspection processes and restoration systems along with software for field strength and loading evaluation. Nelson has been a member to the National Electrical Safety Code (NESC) for 32 years where he has served as Chairman of the Strength and Loading Subcommittee, Chairman of the full NESC committee from 2016 until March 2023, and is currently the immediate past Chairman. Nelson is also Vice Chairman of the Accredited Standards Committee O5 which develops standards for new wood poles and crossarms. While active on the NESC, Nelson also worked at Osmose for over 30 years. [email protected]

Robert Batchelor

Robert Batchelor is the Associate Product Manager – Pole Inspection and Treatment at Osmose. He holds a BS in Chemistry from Armstrong University. He is an active member of AWPA and ASC 05, which provides standards and dimensions for wood poles. In his current role, he oversees the design, development, and implementation of Osmose’s industry-leading wood pole inspection and treatment products and services. [email protected]