Terna Transforms Its Maintenance Strategy

The Italian transmission system operator manages about 800 grid transformers throughout the country. Because of the increasing age of its transformer fleet and criticality of the assets, Terna Rete Italia SpA has taken significant steps to prevent failures and focus on asset maintenance based on the real condition of a transformer’s insulation. As a result, the failure rate of transformers has been well below 1% for several years now.

The main causes of transformer failure — namely, the occurrence of unpredictable external events such as overvoltages, lightning strikes and through-fault currents — have been identified as an indirect cause of winding displacement on autotransformers and electrical failures on grid transformers interconnected to the medium-voltage (MV) network.

In the past, time-based maintenance (monitoring) and condition-based maintenance (remedial action, like replacement) were standard practices for maintaining transformers. However, in the last few years, a new criterion based on advanced analytic tools has replaced Terna’s traditional maintenance strategy.

Maintenance Process

The goal of a maintenance process is to keep the reliability of assets at an acceptable level over their technical life to reduce the likelihood of failure. The condition assessment process and tools must be not only be reliable and comprehensive but also economically effective and efficient. Efficiency is an important driver for an asset manager. Because an aging asset can be stressful in terms of resource availability, an optimized asset management strategy is required.

Continuous on-line monitoring was developed to meet those needs. It continuously assesses the condition of an asset while it is in service. A benefit of this technology is the ongoing availability of operating data directly from the field.

Terna has been using continuous on-line monitoring since the 1980s, first for the most relevant equipment on its extra-high-voltage (EHV) and high-voltage (HV) transmission system, namely, power transformers. More recently, the transmission system operator (TSO) developed a high-voltage monitoring system, or sistema monitoraggio alta tensione (SMOAT), to monitor through-fault currents (TFC) continuously on the majority of its on-line HV equipment.

A Key Parameter

Terna took new parameters into consideration to reduce its major failure rate, using on-line monitors and a health index (HI). Among the possible unpredictable causes leading to a failure, TFC seems to play a major role. The speculation is it may be possible to reduce the part of the fault where cumulative stress from the TFC event can lead to the final breakdown.

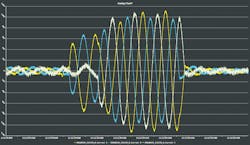

TFC is a transient overcurrent generated by a fault external to the transformer, which produces electromagnetic forces proportional to the square of the peak of the fault current. In some cases, current flowing through the transformer is higher than normal but sufficiently high to activate the transformer protection.

In other cases, the event also can be quite high and the fault gets cleared by the protection closer to the fault, which can be remote from the transformer, thus without activating the transformer protection. Although such a current is not high enough to cause winding deformation, speculation is recorded regarding the aggregate effects of TFC on transformers. These lower TFCs potentially produce mechanical stresses that result in the progressive weakening of the winding clamping pressure and, therefore, movement of the winding turns.

Repetitive occurrences of these events can weaken the mechanical structure of the winding to a point where the transformer is no longer capable of withstanding a short circuit, resulting in severe winding displacement.

Another possible consequence of the continuous movement of the winding disks is the occurrence of inter-turn short circuits. Winding clamping forces in combination with the condition of the windings, insulation, key spacers, blocking and other cellulose products subject to short-circuit forces can degrade over time, if affected by repetitive, moderate short overcurrents. Some of these events will also be recorded by disturbance recorders.

Unfortunately, Terna could not use disturbance recorders to prevent transformer failures for several reasons:

- Because disturbance recorders are driven by the protection relay, and not the current itself, the reliability of the data being captured depends on relay reliability and settings.

- They generally are used to support post-failure investigation, not for predictive maintenance and condition monitoring.

- They do not record inrush currents.

- They do not send notifications.

- They do not send data.

- They do not extract parameters automatically; instead, they just store the waveform in COMTRADE format.

Most of the time, Terna’s operation and maintenance staff is unaware of the number and magnitude of short-circuit current events affecting the grid transformers. Terna owns about 133 transformers, which interconnect the HV grid system to the MV network. In these locations the protection on the MV side of the transformers is managed by the distribution system operator (DSO). Whenever a short-circuit occurs on the MV bus bars, the DSO protection clears the fault before the grid transformer’s HV circuit breaker opens.

These faults cause high currents within the HV/MV transformer, but Terna does not receive a notification for two reasons:

- The transformer HV protection relay does not open.

- In the older grid substations, disturbance recorders are installed on the TSO side of the HV/MV transformer. Therefore, the TSO is unaware of the high currents circulating in the winding until the transformer trips.

TFC Monitoring

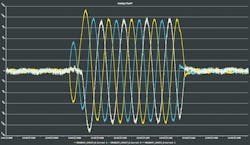

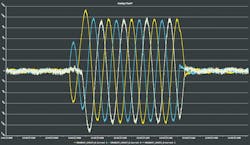

A TFC monitor was installed as a trial in a HV/MV substation equipped with a 63-MVA transformer. This transformer was selected for two key reasons:

- It contains a disturbance recorder, enabling Terna to validate the TFC monitor by comparing the readings with those recorded by the disturbance recorder.

- An inductance variation of 1.5% (from the factory measurement) was detected in the central phase of the transformer in 2015.

The latter reason was critical to understanding the importance of a TFC monitor. Firstly, this installation reduces the maintenance cost by planning the off-line measurements depending on the frequency of a TFC occurrence instead of an annual maintenance check. Secondly, it is extremely important to determine the correlation between the occurrences of TFC with possible inductance variations.

SMOAT System

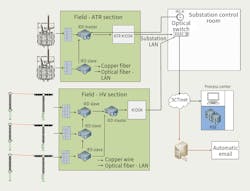

Introduced in 2008, Terna’s SMOAT system is now fully operational, monitoring grid substations, HV/MV transformers circuit breakers, current transformers and capacitor voltage transformers. The SMOAT sensors acquire the relevant parameters. An intelligent electronic device (IED) processes the data received, through fiber-optic or copper wires, from sensors and transducers. All the relevant values then are transmitted, using proprietary fiber-optic cables and IEC 60870-5-104 protocol, to other existing systems such as the operation support platform.

The main constraint is fully observing cybersecurity policies. For this reason, the protection and control system is completely independent from the on-line monitoring system.

Network communication takes place through a dedicated local area network (LAN). For a digital substation with an automation system, the same LAN is used; however, networks have a separate subnet from the control system.

Since 2018, Terna has installed the SMOAT system in more than 25 grid substations, covering many transformers, auto-transformers, circuit breakers, capacitor voltage transformers, current transformers and surge arresters. Grid substations similarly are being equipped with the SMOAT system in accordance with a three-year development plan from 2019 to 2021.

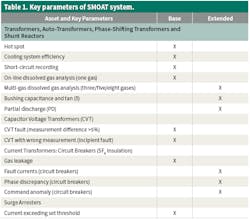

For each piece of HV equipment, Terna identified a specific list of key parameters to monitor. For most of them, Terna seeks to determine two levels of on-line monitoring: the basic-parameter and the extended parameter.

The human-machine interface (HMI) is the health of the on-line monitoring system. With the SMOAT system, Terna aims to enhance its on-line monitoring system by providing the data necessary for condition-based maintenance criteria and, in the future, putting predictive maintenance in place. In fact, the coupling of on-line monitoring and condition-based maintenance ensures optimal results in maintaining the installed fleet’s efficiency.

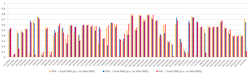

Strong Results

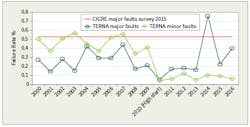

The number of major faults that have occurred in Terna’s transformer fleet since 2000 is independent of the TSO’s adoption of the health index (SMOAT + TFC). Major faults often are unpredictable, attributable to atmospheric lightning or sudden internal collapses. However, the number of less-relevant minor faults decreased dramatically following the adoption of the health index in 2010. The proposed methods can use both off-line and on-line inputs, but its effectiveness is maximized in on-line acquisitions, providing a holistic approach and reducing costs.

Terna has seen significant benefits since monitoring the occurrence of TFC events in grid transformers. A trial was completed with strong results. The results showed several important events affected the transformers that interconnect the HV transmission lines with the distribution network, because of the large number of failures that occur on the MV side of the HV/MV transformer. These occurrences could provide evidence of a correlation between TFC occurrences and grid transformer failures.

By installing TFC monitors, Terna now is aware of the electrical and mechanical stresses affecting its transformers and can schedule corrective maintenance or perform further investigation.

The SMOAT system was developed with the aim of monitoring all devices installed in Terna’s grid substations. Since the installation of SMOAT, data previously available on a local basis now can be downloaded from the Terna intranet. This is just one of the reasons why Terna will continue to invest in the installation of its SMOAT system in more than 20 grid substations over the next two years.

Acknowledgment

Terna would like to acknowledge the support and assistance given by Camlin Power for the development of the trial TFC installation in 2015 as well as Siemens SpA for its support with the first installation of the SMOAT system in 2008-2009.

For more information:

Camlin Power | www.camlingroup.com

Siemens | http://siemens.com

About the Author

Fabio Scatiggio

Fabio Scatiggio is the chemical laboratory manager at Terna Rete Italia SpA. Scatiggio is chairman of TC 10 (fluids for electrotechnical applications) of the Italian Electrotechnical Committee and the Italian representative of both the International Electrotechnical Commission (IEC) and CIGRÉ. As a senior member and reviewing author for IEEE, Scatiggio has published many technical papers on IEEE scientific bibliography, with a focus on transformer diagnostics by dissolved gas analysis, problems related with the presence of corrosive sulfur in oil, health index of transformers and vegetable insulating esters. Scatiggio received the IEC Award 1906 in 2008 and was awarded CIGRÉ’s Distinguished Member status in 2012.

Francesco Maria Pepe

Francesco Maria Pepe received a bachelor’s degree in energy engineering and MSEE degree from the Sapienza University of Rome in 2013 and 2016, respectively. He joined Terna Rete Italia SpA in 2016 as a substation engineer, dealing mainly with power transformers, synchronous condensers and on-line monitoring systems. Pepe is a member of Italian Electrotechnical Committee TC 14 (transformers) and a CIGRÉ Young Member.

Simone Sacco

Simone Sacco graduated in electrical engineering from the Sapienza University of Rome in 2002. He joined Terna Rete Italia SpA as a coordinator in the engineering department. He coordinates all activities on power transformers, shunt reactors and phase-shifting transformer technologies. In particular, Sacco deals with life-cycle management, from the technical specifications to post-mortem analysis. He is a member of CIGRÉ and the Italian Electrotechnical Committee TC 10 (fluids for electrotechnical applications) and TC 14 (transformers).

Claudio Angelo Serafino

Claudio Angelo Serafino is an expert in commissioning and routine testing on high-voltage equipment, including circuit breakers, disconnectors, surge arresters, gas-insulated systems, current transformers and voltage transformers. He also has experience in commissioning and routine testing on protection systems for high-voltage plants, high-power generators and transformers. Since 2013, Serafino has worked in Terna Rete Italia SpA’s engineering department as an expert in medium and large power transformer tests and technical specifications. He is a member of the Italian Electrotechnical Committee TC 14 (transformers).