Arc flashes release energy hotter than the surface of the sun, spray molten metal and create sound blasts as loud as a gun. Each year, thousands of arc flash incidents occur, resulting in burn injuries, hospitalizations and fatalities.

Arc flashes occur when a flashover of electric current leaves its intended path and travels through the air from one conductor to another or to ground, according to the Occupational Safety and Health Administration (OSHA).

Electric utilities can protect their field workforce from the dangers of arc flash in several key ways, including investing in proper personal protective equipment (PPE). For example, a 40 cal/cm2 arc flash suit saved a worker’s life when he experienced an arc flash while racking in a 5-kV 1200-A substation breaker. In addition, utilities must comply with the current guidelines governing arc flash protection.

Understanding the Rules

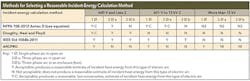

The current federal and state rules and regulations include Federal OSHA-29, CFR 1910-269, 1926 Subpart V and consensus standards NESC – 2017, and NFPA 70E – 2015. As part of the 1910.269 hazard assessment, the employer shall assess the workplace to determine if each employee is exposed to hazards from flames or from electric arcs. The employer also must estimate the available heat energy. For each employee exposed to hazards from electric arcs, the employer shall make a reasonable estimate of the maximum available heat energy to which the employee would be exposed. Finally, an employer may choose a method of calculating incident heat energy that reasonably predicts the incident energy to which the employee would be exposed.

The employer shall ensure that each employee who is exposed to hazards from electric arcs wears clothing with an arc rating greater than or equal to the estimated heat energy. Whenever that estimate exceeds 2 cal/cm2, PPE shall cover the employee’s body.

OSHA considers some of these methods reasonable for exposures below 600 V, but some are reasonable for up 15-kV exposures. For those exposures above 15 kV, the ARCPRO method is recommended. This method helps utilities select protective clothing by defining the arc hazard for workers who may be exposed accidently to electrical arcs. It provides the user with calculations including heat exposure, total heat flux and heat energy on a surface at various distances from an electric arc. The user can then specify clothing that will withstand the level of predicted arc hazards.

Complying with Consensus Standards

NFPA70E offers electrical safe work practices for the industry. As such, utilities can use this how-to-comply instruction manual for several of OSHA’s regulations including electrical hazard assessments and how to select the appropriate PPE for electrical hazards.

OSHA enforces compliance to NFPA 70E using Section 5(a)(1) of the Occupational Safety and Health Act of 1970, which is commonly referred to as the general duty clause, as the basis for implementation. The general duty clause states that employers “shall furnish to each of its employees employment and a place of employment, which are free from recognized hazards that are causing or likely to cause death or serious physical harm to employees.”

As a result, companies can be cited by OSHA for non-compliance of NFPA 70E. Case in point: a major U.S. corporation experienced an electrical accident resulting in serious burn injuries to an electrical apprentice employee. After investigating the incident, OSHA issued a number of citations.

In this case, OSHA contended that the employer violated a federal regulation because it did not provide or require that the electricians wear flame-resistant or flame-retardant PPE, specifically flame-resistant coveralls and insulated gloves. In addition, OSHA contended that the employer violated a regulation when it did not provide or require that its electricians wear appropriate face protection.

The employer challenged the citations, and the disagreement wound up before the Occupational Safety and Health Review Commission. In the settlement, the employer agreed to develop hazard analyses in accordance with the PPE provisions contained in NFPA 70E. OSHA agreed that given the present state of its standards and regulations, the hazard analyses would achieve compliance with their requirements.

Another industry standard, ANSI/IEEE C2 – National Electric Safety Code (NESC), has similar requirements to OSHA in its 2017 edition. It states, “The employer shall ensure that an assessment is performed to determine potential exposure to an electric arc for employees who work on or near energized parts or equipment.”

If the assessment determines a potential employee exposure greater than 2 cal/cm2 exists (see Neal, Bingham, and Doughty [B59]), the employer shall require employees to cover the entire body with arc-rated clothing and equipment having an effective arc rating not less than the anticipated level of arc energy.

Selecting Clothing

To effectively protect their field workforce, employers must understand the Arc Thermal Performance Value (ATPV) of arc-rated clothing. This incident energy on a fabric or material results in sufficient heat transfer through the fabric or material to cause the onset of a second- degree burn based on the Stoll curve.

ATPV indicates the level of protection provided by flame-resistant clothing as measured in cal/cm2. An arc rating (ATPV) means that you have a 50% chance of being burned if exposed to an electric arc with the same number of calories of heat. The fabric will usually not break open unless exposed to energy levels higher than the arc rating.

OSHA requires that the outermost layer of clothing must be arc-rated if any of the following four conditions are met:

• The employee could contact energized conductors or circuit parts rated greater than 600 V.

• An electric arc could ignite flammable material in the work area that could also ignite the worker’s clothing.

• Molten metal from an electric arc could ignite the employee’s clothing.

• The incident energy exceeds 2.0 cal/cm2.

This requirement applies to rainwear, parkas, jackets, safety vests, fall-arrest harnesses or any other clothing worn as the outer layer when employees may be exposed to the hazards of flame and arc.

Layering Garments

Learning how to layer FR clothing the right way can be a great way to meet safety standards while also optimizing comfort and convenience.

During the workday, employees may switch between jobs with different arc-flash protection requirements; however, it’s not always convenient for an employee to switch from an NFPA 70E PPE Category 2 uniform to a PPE Category 3 flash suit. An employee can simply layer an arc-rated coverall over a PPE Category 2 uniform to create a higher combined protection level.

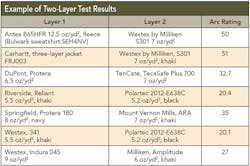

The arc rating of the layered system will be much higher than the single layer, but the actual rating can only be known if the layered system has been arc tested. Many systems have been tested, and the added protection of the layered system is typically quite a bit higher than adding the two arc ratings together.

Because of the safety hazards posed by cotton and the fact that it isn’t considered protective layering by the NFPA, employers may want to eliminate cotton and other flammable materials altogether and layer only with FR clothing.

Annex M of the NFPA 70E regulations states, “The use of all FR clothing layers will result in achieving the required arc rating with the lowest number of layers and the lowest clothing system weight.”

For example, the combination of a daily-wear shirt with an arc rating of 8.7 cal/cm² (HRC 2) and an 8.7 cal/cm² arc-rated coverall over it achieves a 27.2 cal/cm² (HRC 3) level when tested. This layered combination achieves the HRC 3 level and is much easier to carry around and slip into than an HRC 3 flash suit.

Test results show the air layer between garments typically increases the arc rating more than adding the ratings of the two FR garments together. As shown in the above example, the actual layered rating of 27.2 cal/cm² is higher than the 17.4 cal/cm² sum of the two 8.7 cal/cm² ratings.

Most FR layering programs focus on shirts. If providing the same high arc protection for the lower torso, arc-rated coveralls may be needed.

For maximum effectiveness, employers need to communicate layering rules. It is recommended to organize a layering system into various levels and develop a chart to show employees which garments will layer up to meet the various levels. The employees can use this chart to quickly determine which garments will provide the proper protection level for their assigned tasks.

By providing field workers with the proper PPE and complying with rules and regulations, electric utilities can help to protect their workforce from arc flash hazards, which claim the lives and livelihood of many employees each year.

Mike Bahr is the TMW safety coordi-nator for Tri-State Generation and Transmission.