The Namdaran Transmission System Co. is responsible for the design and replacement of 400-kV, 230-kV and 132-kV traditional insulators installed on the overhead-line transmission system in southern Iran. This section of the network supplies electrical energy to a large geographical area, including the capital city of Tehran. During the summer, most of the demand comes from supplying air-conditioning equipment installed in industrial premises, commercial buildings and residential homes.

The climatic conditions in locales near the Persian Gulf and Oman Sea are challenging, with summer (and sometimes spring) temperatures exceeding 50°C (122°F) as well as humidity levels between 90% and 95%. The highest level of humidity creates considerable salt pollution from the nearby saltwater bodies.

Since 2012 and the war in Iran, the climate has changed in the deserts of Saudi Arabia and Turkey, and the narrow gulfs in Iran are now dry and devoid of water. Hence, the surface pollution of the overhead-line insulators and substation plant bushings in these dust bowls has increased substantially. Also, these conditions give rise to severe salt pollution of the transmission overhead-line insulators in the coastal region.

Insulator Types

Most of the overhead-line insulators installed in the area are made of porcelain and glass disc, supplied by major manufacturers who specify the insulators must be washed periodically. To wash the insulators, it is necessary to have access roads to the towers, use special machines and distilled water, and employ trained personnel.

The existing equipment to wash the insulators is old and has not been used for years, and there is a shortage of drinking water in these areas. Therefore, transmission line maintenance utilities do not have sufficient equipment and distilled water to regularly wash the insulators, which has resulted in excessive accumulation of pollution. The insulators are now in a critical condition.

Transmission System Failure

In April 2017, even though the temperature was not too high, insulator pollution caused the 400-kV, 230-kV and 132-kV transmission system to collapse. Fortunately, the swift action and special measures taken by the Iran Grid Management Co. (IGMC) avoided a total blackout.

This major transmission system collapse prompted the Iran Minister of Energy, supported by deputies and responsible organizations established in Khuzestan, to act on resolving the cause of the local shutdowns associated with the polluted insulators.

In an emergency meeting, the following recommendations were approved for immediate action:

• Replace all porcelain and glass disc insulators on the 440-kV, 230-kV and 132-kV overhead-line insulators with high-quality composite material insulators.

• Have all 16 electric utilities in Iran deliver their existing washing equipment and personnel to Khuzestan to perform immediate remedial action in the form of washing the existing polluted insulators and bushings.

• Cover bushings in all substations with a high-performance room-temperature-vulcanizing (RTV) rubber silicone coating.

• Install new substations in the area indoors with the gas-insulated substation (GIS) plant.

• Give the Namdaran Transmission System Co.’s (NTS) consulting engineering arm responsibility for estimating the number of insulator strings required for each voltage level to contract tendering prior to replacement. Results indicated the need to replace 50,000 insulator strings in phase 1 and 90,000 in phase 2.

Composite Insulators

In Iran, composite insulators for use in highly polluted areas are available from five companies. However, to comply with the NTS procurement policy, tenders for the supply of composite insulators must be obtained from two companies. As there are several compounds from which silicone insulators are made, care was taken to select the replacement insulators from a company whose products have been type-tested by a trusted laboratory and are certified by the International Laboratory Accreditation Cooperation (ILAC).

The design specification for the existing disc insulators specified a creepage distance of less than 31.5 mm/kV (1.24 inches/kV), but the specified creepage distance for the proposed replacement composite insulators is more than 40 mm/kV (1.57 inches/kV). The length of the replacement insulator strings is the same as that of the porcelain and glass insulator strings.

In parallel, the Research Institute of Iran conducted a salt fog test (1000 hours) and ultraviolet tests on a sample of insulators. For even more confidence in product quality, the NTS examined documentation for all the imported raw materials and compounds.

Short-Term Results

In accordance with the recommendations of the emergency meeting, the Khuzestan Regional Electric Co. (KZREC) has started washing the polluted overhead-line insulators and apply RTV coatings on substation equipment bushings. Early indications suggest system performance with respect to system fault outages has improved. The plan to replace insulators with locally purchased silicone units is in place and should be completed later in 2018, following the period of excessively high temperatures.

KZREC also has started washing the polluted bushings on substation equipment prior to applying the RTV coating. This work will continue to be conducted in parallel with the replacement of existing overhead-line insulators with the new silicone insulators, which will take place after the peak summer period of high temperatures.

Application Questions

The severe insulator and bushing pollution in southern Iran has resulted in the need to question the application of some elements of the International Electrotechnical Commission (IEC) standards in highly polluted environments, which system design staff could apply to install transmission systems with a minimal risk of outages.

Following are some of the questions that should be asked:

• Is the selection of composite or silicone insulators the solution for areas of high pollution?

• Should the raw materials that comprise composite insulators be changed for highly polluted areas?

• Is the washing of insulators the solution and what is the recommended frequency?

• Do composite insulators require regular washing? If so, are there specialized tools to move along conductors and automatically wash the insulators?

Foreseeable Future

While the major transmission system fault experienced by NTS that caused interruptions to supplies is not unusual, it generally is associated with the lack of a time- or conditioned-based maintenance policy. This was the case with NTS, where several extreme political circumstances and demanding environmental conditions resulted in a lack of maintenance and severely polluted overhead-line insulators and plant bushings.

While the interruptions to supplies were minimized, they resulted in a series of recommendations and a long-term strategic plan that takes advantage of the latest technologies to improve the security of supply for the foreseeable future.

Acknowledgement

The author wishes to thank the KZREC management team — Dashte Bozorg, the managing director, and the utility’s deputies and colloquies, Mr. Ganavati, Mr. Golshani, Mr. Farokhi and Mr. Badieefar. Special thanks also to Mr. Hojjat, the former managing director of IGMC, and the teams of Mr. Mohammadi and Mr. Khorram for all their valuable advice and work on this project. ♦

Mohsen Arabani is the managing director of Namdaran Transmission System Co. He holds a BSEE degree from the Sharif Technical University in Tehran as well as a master’s degree and Ph.D. in power systems from the Polytechnic University in Bucharest, Romania. Arabani worked for Moshanir Power Engineering Consultants with the Iran Ministry of Energy for more than 30 years in various roles as manager of overhead lines, substations, research and development, and overseas departments. In parallel, Arabani was a lecturer at the Polytechnic University of Tehran.

Sidebar: Electricity Industry in Iran

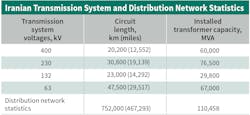

The electric industry in Iran is responsible for infrastructure vital to the country’s economic and social growth. Currently, the urban and rural population, which totals 80 million people, has full access to electrical energy.

Iran has mid-term and long-term plans in place to implement the following policies:

- Network expansion coupled with increased stability and controllability

- Development of clean energies to provide environmental protection

- Development of digital infrastructures

- Introduction of new technologies to improve system efficiency.

The installed generating capacity in Iran is some 76,000 MW, of which 22% is based on conventional thermal plant, 36% gas-fired plant and 25% combined-cycle plant. The remaining installed capacity is 15% hydroelectric power plant, diesel, nuclear and renewable energy plants. Iran plans to increase its installed capacity to 85,000 MW in 2018.

Plans also are in place to increase the installed capacity with combined heat and power (CHP), combined cycle heat and power (CCHP) and distributed generation plants through build-operate-transfer (BOT) and build-operate-own (BOO) contracts.

In line with the policies adopted by the Ministry of Energy in Iran to exchange electrical energy with neighboring countries, Iran now has interconnections with Azerbaijan, Armenia, Afghanistan, Iraq, Nakhjavan, Pakistan, Turkmenistan and Turkey — with a total load-transfer capacity of some 10,000 MW. These power exchanges enable a reduction in spinning reserve, improved system reliability, environmental load dispatch and energy to supply peak load demands.

About the Author

Mohsen Arabani

Managing Director

Mohsen Arabani is the managing director of Namdaran Transmission System Co. He holds a BSEE degree from the Sharif Technical University in Tehran as well as a master’s degree and Ph.D. in power systems from the Polytechnic University in Bucharest, Romania. Arabani worked for Moshanir Power Engineering Consultants with the Iran Ministry of Energy for more than 30 years in various roles as manager of overhead lines, substations, research and development, and overseas departments. In parallel, Arabani was a lecturer at the Polytechnic University of Tehran.