Among the five provinces served by the China Southern Power Grid (CSG), the western provinces, including Yunnan and Guizhou, are rich in water resources and have a low demand for electricity. On the contrary, the eastern province of Guangdong lacks water resources yet has a huge power demand because of its well-developed economy.

CSG began to develop a transmission plan for an additional 11,500 MW to 13,500 MW to be transferred from west to east, to Guangdong. In 2003, the utility launched a series of feasibility demonstrations and studies on power transmission levels and capacities. Included were the practicability and cost-effectiveness of an ±800-kV dc transmission line linking the hydropower plants in Yunnan to load centers in Guangdong. The studies confirmed the growing power demand in eastern China required construction of the ±800-kV power transmission project. This west-to-east transmission project offers a large load-transfer capacity over a distance of more than 1,400 km (870 miles) with high efficiency.

Yunnan-Guangdong Project

Founded in December 2002, CSG is responsible for the investment, construction, operation and management of the southern power grid across five provinces: Guangdong, Guangxi, Yunnan, Guizhou and Hainan. This is a service area of 1million sq km (386,102 sq miles) supplying energy to a population of 230 million through a transmission system characterized by long distances and a large capacity that includes high-voltage alternating-current (HVAC) and high-voltage direct-current (HVDC) circuits operating in parallel.

The Yunnan-Guangdong project crosses Yunnan, Guangxi and Guangdong, starting at Lufeng, Chuxiong, Yunnan, in the west and ending at Zengcheng, Guangzhou, Guangdong, in the east. This project has a rated voltage of an ±800-kV dc, a capacity of 5,000 MW and a transmission distance of 1,418 km (881 miles). The main parts of the system are the Chuxiong converter station, the Suidong converter station, the dc transmission lines and electrodes at both ends.

This major HVDC project transmits clean energy from Yunnan, Xiaowan, and other hydropower stations to the load center of the Pearl River Delta region. CSG decided to adopt an ±800-kV HVDC line because it increases the transmission efficiency by reducing line losses by 40% and reducing the land required for the right-of-way compared with a ±500-kV dc option. Furthermore, it will solve the problem of excessive short-circuit current at the receiving end load center, hence improving the safety and stability of the power grid.

Converter Station Challenges

At the sending end of the Yunnan-Guangdong project, the Chuxiong converter station is at an altitude of about 1,850 m (6,070 ft), so the external insulation (including air clearance and creepage distance), electromagnetic environment and test voltage parameters had to be corrected accordingly. The external insulation of equipment was determined to take into account aging problems caused by intense ultraviolet radiation. For the main equipment, especially the 800-kV converter transformers, the width limit of 3.5 m (11.5 ft) for the railway transportation of equipment to Chuxiong imposed a strict design condition.

The Yunnan-Guangdong dc system at the sending end has two operational conditions: parallel operation with the ac system and isolated operation. The dc system had to be designed to satisfy the two operating conditions. The Chuxiong converter station is linked to the Xiaowan and Jinanqiao substations by two 500-kV ac transmission lines. In addition, it also is linked to the 500-kV Heping substation (Kunxibei substation) in the main grid of Yunnan by two 500-kV ac lines. A situation in which only the Xiaowan or Jiananqiao substation is connected to the Yunnan-Guangdong dc transmission lines would be deemed an isolated operational condition.

The converter station at the receiving end is located in a heavily polluted area. With an equivalent salt deposit density up to 0.066 mg/sq cm (4.26 mg/sq inch), the design of the external insulation of equipment and the installation height of dc switchyard equipment proved challenging. The Yunnan-Guangdong ±800-kV dc transmission system shares the grounding electrodes on the Guangdong side with the ±500-kV dc transmission system. Therefore, the problems related to the design of the electrodes and the operation of these two dc systems, arising from the shared grounding electrodes, had to be overcome.

Overvoltage and Insulation Coordination

Installing arresters at appropriate locations is a key measure taken to reduce transient overvoltages, but the configuration of arresters in ±800-kV dc systems is complex. To minimize the transient overvoltage arising from switching or faults, the configuration scheme for this project was determined in conjunction with the voltage/current characteristics of the arresters. Additionally, smoothing reactors are installed separately at the pole line and neutral line to reduce the overvoltage level on the high-voltage pole line.

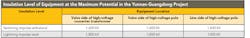

The corresponding withstand voltage of switching impulse and lightning impulse in the previous ±500-kV dc systems in China is 1,300 kV and 1,550 kV, respectively. Compared with the linear extrapolation from the ±500-kV dc insulation level, both the overvoltage and the insulation levels of the equipment used in the ±800-kV dc project are substantially reduced through reasonable arrester protection and insulation coordination. The results from the research CSG had performed earlier made it possible to reduce the research and development (R&D) complexity and manufacturing cost of the equipment on the premise that sufficient safety margins would be maintained.

Temporary Overvoltages

The isolated operational mode is of significant importance to improve the transmission capacity and troubleshooting capability of the power grid. It imposes strict requirements on the overvoltage suppression and control sequence of the Yunnan-Guangdong project. In case of isolated operation of the dc system on the Chuxiong side, the temporary overvoltage (double dc poles blocked successively) of up to 1.57 p.u. may occur, so the following necessary technical measures were taken:

- Four interrupter circuit breakers were used at the incoming lines of four ac filter banks, and double-interrupter circuit breakers were used as the filter sub-banks. The circuit breakers of ac filter sub-banks can be tripped only when the ac overvoltage of the Chuxiong converter station is lower than 1.3 p.u.

- In isolated operation, the circuit breakers of ac filter banks at the Chuxiong converter station were set to be disconnected 100 msec after bipolar blocking of the Yunnan-Guangdong dc system.

- The dc control and protection system was designed so that all circuit breakers of converter transformers would not trip before ac filters in the event of dc bipolar load rejection.

- Two-column arresters were used for ac bus bar at converter stations instead of single-column arresters to improve the ability of energy dissipation.

External Insulation

At the sending end, because the Chuxiong converter station is at high altitude, external insulation and test voltage parameters had to be designed accordingly. Meanwhile, as heavy pollution prevailed at the receiving end, the external insulation of the ±800-kV dc system involved several considerations:

- Air clearance and altitude correction

- Pollution in the Yunnan-Guangdong dc line corridor and station sites as well as operational experience

- Pollution flashover characteristics of insulators under the conditions of high altitude, pollution and ice coating

- Characteristics of dc composite insulators and application of external insulation at converter stations under polluted conditions

- Development of dc composite insulators as well as a full-voltage and full-size pollution characteristic test

- Lightning protection and the grounding of dc lines.

Composite insulation material is an effective way to solve the excessive structural height of porcelain post insulators for the ±800-kV dc converter station in a polluted ambient environment. The research confirmed the specific creepage distance of composite insulators is 75% that of porcelain insulators, thus the structural height of composite post insulators was designed with a length of 10 m (33 ft).

Electromagnetic Environment

The biggest problem in designing the electromagnetic environment is the lack of a standard. The dc resultant electric field, ion flow, dc magnetic field, radio interference (including television interference) and audible noise have to be taken into account for the electromagnetic environment of dc projects. Based on intensive study, the following standards were adopted for the Yunnan-Guangdong project:

- Maximum resultant electric field strength at the ground level under lines is 30 kV/m

- Maximum resultant electric field strength near buildings is 25 kV/m and 80% of its measurements shall not be greater than 15 kV/m

- Ion flow density below lines is 100 nA/sq m

- Control index of the dc magnetic field is 10 mT

- Control index of the radio interference for 800-kV dc transmission lines is 55 dBmV/m

- Audible noise is 50 dBA in ordinary areas under good weather conditions and is checked against 45 dBA in densly populated areas.

Converter Valves

Converter valves are designed with 127-mm (5-inch) light-triggered thyristors. These valves are installed using air-insulated, water-cooled, suspension-type, indoor double-valve structures. In addition to the new structural design, the greatest technical challenge in terms of converter valves was the type tests, including the multiple-valve insulation test, operational test, and testing other items and criteria. Furthermore, the current capacity of traditional 127-mm (5-inch) light-triggered thyristor valves is 3,000 A; however; the rated dc current of the Yunnan-Guangdong project is 3,125 A. Therefore, the technical performance of the thyristors required optimization.

Converter Transformer

A total of 28 single-phase, double-winding converter transformers are provided for the two poles of each station with four serving as standby. The delta-star converter transformer was the most difficult equipment to manufacture.

External lead-out devices are used at the valve side to accommodate transportation limits. Specifically, width could be no greater than 3.5 m. The site installation tolerance of lead-out devices at the valve side is small and the process is complex. Therefore, a special mounting platform and tools were required.

Vacuum on-load tap changers are used for converter transformers for the first time. Their structural dimensions are relatively small, which can help relieve the difficulties in designing the dimensions of the converter transformers.

Dry-type bushings are installed on the valve side, as the length of bushings on the valve side manufactured for the ±800-kV converter transformers is almost up to the maximum design length.

Dry-Type Smoothing Reactor

Four dry-type, air-cored and naturally air-cooled smoothing reactors are installed per pole in each converter station, being series-connected to the pole bus bars and neutral bus bars with an additional one as standby. Compared with the previous oil-immersed smoothing reactors, this dry-type structure can reduce design and manufacturing difficulties significantly.

A Foundational Project

The total cost of the Yunnan-Guangdong project was 15.4 billion yuan (US$2.4 billion), of which 7.9 billion yuan (US$1.23 billion) was invested in converter station equipment. Since commissioning the Yunnan-Guangdong project in June 2010, the HVDC system has operated in a stable and smooth manner. This is a measure of the high standards adopted in the various stages of system studies, design, manufacturing, installation, commissioning and operation. The Yunnan-Guangdong project has effectively alleviated the power-supply shortage of the Guangdong power grid, rendering good economic and social benefits.

This project provides a solid foundation for subsequent projects in terms of the research, manufacturing, development, design and operation of ultrahigh-voltage equipment. Furthermore, it serves as a demonstration for subsequent planned projects that will transmit electricity from the large hydropower stations at Nuozhadu and Xiluodu to the load centers. The successful construction of the Yunnan-Guangdong project represents an important milestone in China and even in the world’s electric power industry.

Qi Da-Cai ([email protected]) was awarded a Ph. D. by Tsinghua University in 2004 and, during his career at China Southern Power Grid Co. Ltd., he has held engineering posts in power project construction and power system operation before embarking on his managerial career. Since 2002, Dai-Cai, who is a professorate senior engineer, has served as vice-general manager of CSG.

Lu Jin-Zhuang ([email protected]n) was awarded a Ph.D. by the North China Electric Power University in 2004 and, during his career at China Southern Power Grid Co. Ltd., he has conducted over-voltage and insulation coordination research on the HVDC and UHVDC power transmission project.

Companies mentioned:

CSG| http://eng.csg.cn/

NARI-Relays Electric| www.nrelect.com

Siemens| www.siemens.com

TBEA Shenyang Transformer Group| www.tbea-sb.cn

Tianwei Baobian Electric | www.twbb.com

Xi’an XD Power System | www.xdps.cn

XJ Group | www.xjgc.com