Batteries Underpin Grid Control System

Snohomish County Public Utility District (PUD), based in Everett, Washington, U.S., has installed the first of several energy storage systems aimed at transforming the marketplace and how utilities manage grid operations. The PUD project is the first battery storage system built on the cutting-edge Modular Energy Storage Architecture (MESA).

Located at a utility substation near the PUD’s operations center, the energy storage system is designed to improve reliability and the integration of renewable energy sources, which are rapidly growing in the Pacific Northwest. The project was made possible in part by a US$7.3 million investment from the Washington State Clean Energy Fund.

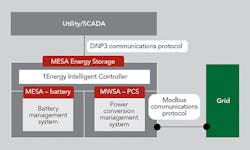

Snohomish County PUD recognizes the electrical grid needs to change to take on more renewable power. MESA’s standards-based energy storage systems and software will play major roles in that change. MESA provides standard interfaces among equipment components, such as the power conversion system, batteries and control system, and reduces the complexity of projects and lowers costs. The system offers a nonproprietary and scalable approach to energy storage.

First Systems

The program, which forges partnerships with major U.S. and international business partners, includes two large-scale lithium-ion (Li-ion) batteries, one manufactured by GS Yuasa International Ltd. and supplied by Mitsubishi International Corp., and a second manufactured by LG Chem. Both Li-ion batteries will use a Parker Hannifin power conversion system. Later this year, the PUD will deploy multiple advanced vanadium flow batteries, built by UniEnergy Technologies, at a second PUD substation.

1Energy Systems, the PUD’s principal program partner, is the architect of the MESA software controls. The current energy storage industry, 1Energy emphasizes, is a smorgasbord of batteries, power control systems and voltage converters, all of which have required custom engineering to make the system functional.

One of the challenges with past energy storage projects is each one has been its own black box project. Each has required a lot of nonrecurring engineering costs to make the battery system talk to the power conditioning system, and talk to the utility’s systems such as the supervisory control and data acquisition system (SCADA) and the distribution management system (DMS). The MESA software creates a common thread. It is what knits all these things together in a way that promises to unlock the full potential of energy storage.

MESA Origins

The PUD began exploring energy storage systems in 2011 as intermittent resources, such as wind and solar, began to contribute more and more to the utility’s energy portfolio. Battery storage technology is an attractive option given its relatively small physical footprint, affordable investment costs and minimal permitting requirements. The utility chose to site its storage systems at existing substations, which streamlined the site development and approval process as well as ensured a secure location that could be monitored and easily controlled by staff.

When the PUD looked at existing energy storage systems on the market, it did not find anything with a platform that allowed it to implement multiple, customizable operating modes for various use cases. No system with open standards met the utility’s need to integrate its software systems for managing the electrical grid, including its SCADA and DMS.

The lack of standards has resulted in battery systems being configured in various ways that do not allow easy integration of multiple components from different vendors. Batteries from various vendors have different direct-current voltage output levels. Manufacturers of power conversion systems have different direct-current and alternating-current voltage output levels. The lack of standards creates additional challenges for utilities and drives up costs. At the same time, communications between components in energy storage systems are inconsistent and lacking in protocols, which also complicates engineering and drives up costs.

MESA aims to address these issues. The PUD and a collection of public and private industry partners have now developed open, nonproprietary specifications and standards for energy storage systems. MESA eventually will create a marketplace in which battery components become modular, recurring engineering is minimized and costs are reduced.

System Operations

Future energy storage systems could help to resolve a broad range of issues related to electric grid operations. Storage offers benefits related to frequency and voltage support, and it could reduce the need to maintain spinning reserves for backup. Controls integration and optimization software is one of the keystones of the PUD storage program.

The control system involves all of the different storage batteries, each with its own performance characteristics. The software is designed to integrate multiple types of renewable energy. The control system infrastructure is the critical technology for utilities and the energy storage industry, advancing from merely demonstrating individual energy storage projects to creating an easily deployable, scalable solution that can be integrated with other grid assets.

For the PUD, storage changes how it operates its SCADA in that its distribution system has always had one-way operation from generating resources. The utility is working with Alstom Grid to model its distribution system to incorporate energy storage.

Research by the University of Washington and University of Michigan engineering departments reinforce operational benefits, including the significant value of using storage and demand response for arbitrage between periods of high and low demand. It calls out the value of ancillary services such as frequency control, spinning reserves and voltage control. Successful energy storage can reduce line congestion and transmission losses. It minimizes the need to run expensive power plants and spill renewable energy during times of excess energy supply.

During times of the day with high solar energy production, for example, batteries can be fueled for use later in the evening when customers are returning home and demand peaks. When PUD load and market prices are high, there is the potential to draw from the battery to minimize purchases. Local renewable resources provide the fuel, including small hydropower, biogas and biomass, solar and other distributed generation.

To support the PUD project, the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) has developed use cases, or detailed descriptions of the many ways energy storage can increase renewable energy use and improve grid efficiency and resiliency. The PUD is tapping these use cases as it implements and evaluates its energy storage projects. PNNL also is providing analytical and technical support, including conducting benefits analysis, designing test plans and enhancing control strategies.

Technology and Generation Investments

The utility’s role in developing MESA standards is another illustration of its leadership in the research and development of new technologies and energy resources. In 2011, the PUD began generating energy at its Youngs Creek hydropower facility, the first such project in Washington state in nearly 20 years. It is currently designing three additional hydropower projects that could come on-line over the next several years. The utility also has led research to assess tidal and geothermal energy potential in the Pacific Northwest.

An aggressive multiyear smart grid modernization effort will allow the PUD to adopt new technologies that enhance reliability, improve energy management and create operational efficiencies. It was supported by a $15.8 million grant under the American Recovery and Reinvestment Act. The program has several components, including digital communications, substation automation, distribution automation, DMS and cybersecurity. The utility sees energy storage as a critical component of its smart grid investments to take advantage of growth in renewable energy and to maintain strong reliability.

Jason Zyskowski ([email protected]) is manager of substation engineering for Snohomish County Public Utility District. His work for the PUD has included experience in transmission, protection and substation engineering. He holds a BSEE degree from the University of Washington, is a member of IEEE and is a registered professional engineer in the state of Washington.

Neil Neroutsos ([email protected]) is the media liaison for Snohomish County Public Utility District. His experience includes work in energy efficiency, renewable energy development and emergency response. He holds a bachelor’s degree in journalism from the University of Washington and a master’s degree in public relations from Northwestern University, and is

accredited by the Public Relations Society of America.

Sidebar: MESA Project Goals

The main goals of the Modular Energy Storage Architecture (MESA) projects are as follows:

- To develop standard electrical and communications interfaces to connect batteries, power converters and software components into modular energy storage systems.

- To foster a robust industry ecosystem of modular energy storage component suppliers. By sharing their learning with other electric utilities and technology suppliers, MESA partners are advancing a new, component-based approach to energy storage that gives electric utilities more choice and enables battery, power converter and software manufacturers to reach more customers while focusing on their core competencies.

- To enable technology suppliers to focus on their core competencies of facilitating quality, safety and cost-effectiveness.

- To reduce training costs and improve safety of field staff through standardized procedures for safety and efficiency.

Sidebar: PUD Energy Storage Projects

Snohomish County Public Utility District’s Modular Energy Storage Architecture (MESA) projects will include software and system design from 1Energy Systems and Parker Hannifin power conversion systems.

MESA 1 will contain two Li-ion batteries, for a total of 1 MW/1 MWh. The first battery will be manufactured by GS Yuasa International Ltd. and supplied by Mitsubishi, and the second manufactured by LG Chem.

MESA 2 will contain a vanadium flow battery, for a total of 2.2 MW/4.4 MWh, manufactured by UniEnergy Technologies.