By all outward appearances, the transmission grid and distribution network have not changed much over the last 100 years. The conductor is still strung from structure to structure and pole to pole, but these are only surface characteristics and looks can be deceiving. Look a little deeper, and it is easy to see the transformation taking place: Renewable generation is becoming more economical than fossil-fuel-based generation. Customers are now prosumers, capable of producing megawatts of power from their side of the meter, which has turned the grid into a bidirectional power pipeline. Distributed energy resources have started the decentralization process that has been talked about for years.

The edge of the grid is being redefined with power generated where it is consumed. Microgrids are changing the dynamics of grid resiliency. However, the real game-changer has been the addition of energy storage to the grid. The technology is being deployed throughout the delivery system to balance power fluctuations, manage peak demand, make wind and solar dispatchable, and reduce carbon emissions. It is a different grid than ever before, and energy storage is only a small part of the transformation.

Broadening Power

Even lead-acid battery technology has been updated by innovative approaches, such as valve-regulated lead-acid (VRLA), absorbed glass mat (AGM) and gel cell batteries. Researchers found a VRLA battery could be enhanced by adding carbon to the cell. The carbon increased the battery’s performance and lengthened its service life.

Researchers also found a battery could be enhanced by adding a supercapacitor to the lead-acid cell. Called an UltraBattery, the capacitor acts as a buffer for high rates of charge-discharge cycling. An energy storage demonstration project using both a carbon-enhanced battery and an UltraBattery began in 2011 and is still in service today. The project is a collaboration between the U.S. Department of Energy (DOE), Public Service Co. of New Mexico (PNM), Sandia National Laboratories, Electric Power Research Institute, S&C Electric Co., East Penn Manufacturing Co. Inc. and its subsidiary Ecoult, Northern New Mexico College and the University of New Mexico.

Expanding Battery Supply

A lot of potential exists for various battery technologies, but Lithium-ion (Li-ion) technology has become the battery technology of choice for the 21st century grid. Li-ion technology is setting worldwide records for energy storage system deployments. Globally, Bloomberg NEF estimates the industry will need 942 GW of cumulative capacity in the next 22 years, and other marketing research groups agree. The challenge will be producing enough of these batteries to meet the demand.

Interestingly, it was an electric vehicle manufacturer that came up with the solution. Tesla Inc., partnering with Panasonic Corp., developed the world’s first gigafactory to produce large numbers of Li-ion batteries. The Tesla-Panasonic partnership broke ground on the first gigafactory in 2016, and it is still under construction with about 30% complete. Even at 30%, the gigafactory produced 20 GWh of Li-ion batteries in 2018, according to Tesla.

The concept of the gigafactory has caught on with other manufacturers, which now have plans to build their own versions. Announcements have been made worldwide about gigafactories being planned or under construction. Depending on what source is quoted, somewhere near 22 gigafactories are expected to be on-line by 2028. By 2023, Benchmark Mineral Intelligence estimated seven of the top 10 of these large factories will be in China, one in the U.S., one in Korea and one in Poland.

Expanding Functions

When Tesla launched its Li-ion-based energy storage business in 2015, it was associated mostly with residential products, like the Powerwall. However, it did not take long for commercial and grid-scale systems to emerge. In May 2018, the Tesla energy storage business hit a major milestone with its first gigawatt-hour of Li-ion battery capacity deployed. Tesla expects to deploy its second gigawatt-hour of capacity sometime in 2019. This announcement has some energy storage supporters saying, “Tesla is less a car company than a battery company that sells cars.”

Tesla’s energy storage systems got a huge boost in 2017 when company CEO Elon Musk made a wager. He bet Tesla could supply a 100-MW/129-MWh energy storage system for the Hornsdale Power Reserve project in 100 days or it would be free. The owner took Musk up on that bet. Tesla made the completion date with plenty of time to spare (it took just 64 days). That got everyone’s attention, but it has been the 2018 operation of the Hornsdale project that has put it back in the spotlight.

No one disputes the value of storing bulk electricity for later use, but ancillary services are becoming extremely important to the grid’s operation, and Hornsdale’s first year of operation is underlining that importance. The Australian Energy Market Operator (AEMO) reported Hornsdale’s response was more rapid, accurate and valuable than conventional turbines on the system.

This was important because system security required AEMO to contract for 35 MW of capacity for frequency control ancillary services provided by gas and steam turbine owners. After Hornsdale’s first year, AEMO announced it would be ending the 35-MW ancillary service requirement, which had cost nearly US$28.9 million in both 2016 and 2017.

Ancillary energy storage services are proving important to the Los Angeles Department of Water and Power (LADWP), too. LADWP installed a 20-MW/10-MWh battery energy storage system (BESS) at its 250-MW photovoltaic Beacon solar facility in the Mojave Desert. The Doosan GridTech Li-ion energy storage system application is used to stabilize solar generation, and it is providing frequency control, voltage support and power smoothing required by the North American Electric Reliability Corporation (NERC) and Federal Energy Regulatory Commission (FERC).

Gas Turbines Plus Storage

Peaking plants plus energy storage are providing some interesting projects known as hybrids. By integrating gas peaking plants with energy storage systems, the hybrid has proven to be beneficial for both the grid’s operation and the environment. In 2017, Southern California Edison (SCE) and GE commissioned the world’s first hybrid electric gas turbine.

The GE hybrid integrated a 10-MW/4.30MWh BESS with a GE LM6000 gas turbine. What makes this hybrid special is the control system uses the battery supply energy until the turbine reaches full power output, enabling the turbine to be in a cold standby mode. This condition reduces fuel consumption and emissions.

The power plant plus energy storage hybrid application has gained acceptance worldwide. Sinergy Kft, a subsidiary of ALTEO Group in Budapest, Hungary, installed a Wärtsilä/Greensmith 6-MW/4-MWh BESS at a power plant that has three Wärtsilä W34SG natural gas generators. Commissioned in August 2018, this addition was Wärtsilä’s first hybrid system. According to Wärtsilä, it is operating as a virtual power plant and providing frequency regulation services.

Another example is Australia’s Origin Energy, which is installing a 4-MW/4-MWh energy storage system at the 414-MW Mount Stuart power station in North Queensland. Supplied by Korean consortium Bosung Powertec Co. Ltd., the energy storage system will be used for backup power and to integrate local renewable energy. Also, the 178-MW Newman power station in Western Australia will have a Kokam Li-ion battery containerized, 30-MW/11.4-MWh energy storage system as part of the facility.

Offshore Hybrids

The Dominican Republic has a scarcity of land in Santo Domingo, but the city’s electricity needs continue to increase. An unorthodox approach was taken: a floating power plant, called the Estrella del Mar III. Developed by Siemens AG, ST Engineering Ltd. and Fluence, the floating hybrid power plant is a combined-cycle natural gas power plant with 145 MW of capacity combined with a 5-MW/10-MWh Fluence Li-ion BESS. The floating aspect makes the hybrid more cost effective than a land-based power plant. The energy storage attribute reduces emissions from the plant. Estrella del Mar III is expected to be completed and in operation in spring 2021.

Estrella del Mar III is a floating power plant tethered to the shore for operation, but another project is taking energy storage systems out to sea. It is an ultra-deepwater semi-submersible drilling rig owned by Northern Drilling Ltd. and named the West Mira. It will be the first drilling rig in the world to operate with a low-emission hybrid (diesel-electric) power plant and a Siemens BlueVault 6-MW Li-ion energy storage system.

According to Siemens, the BlueVault system will reduce the diesel’s fuel consumption by 12%, decrease the diesel’s running time by about 42%, and cut carbon dioxide emissions by 15% and nitrogen oxide emissions by 12%. This is the first time the technology has been adapted to a drilling rig, but it is not the first time the technology has been to sea. It has been field-tested in more than 60 marine vessels worldwide.

Grid-scale energy storage systems are being combined with offshore wind farms, too. Although these energy storage systems are installed at substations on land, they are still an integral part of the offshore wind farm. Orsted added a 2-MW battery to its 90-MW Burbo Bank wind farm in 2018 for frequency regulation services. After that project, Orsted and its partner Eversource decided to combine a NEC Energy Solutions 55-MW/110-MWh Li-ion energy storage system with its proposed 800-MW Bay State wind farm off the coast of Martha’s Vineyard, Massachusetts, U.S.

Another application of wind plus storage is the 30-MW Hywind floating wind farm off the coast of Scotland. Aggreko plc, formerly Younicos, has installed a 1-MW/1.3-MWh energy storage system to make the wind farm more grid friendly.

EDF Energy included a Nidec Industrial Solutions 49-MW/24.5-MWh Li-ion energy storage system for its 41.5-MW Blyth offshore wind farm and 1332-MW Burton B combined-cycle gas plant in Nottinghamshire county, U.K. This BESS is doing double duty by enhancing electricity produced by the wind farm’s five Vestas 8.3-MW turbines and providing balance for the U.K.’s electrical grid. The battery is part of a new 200-MW frequency response system. According to Reuters, EDF is planning to invest 8 billion euros in energy storage between 2018 and 2035.

Fuel Cells and Flow Batteries

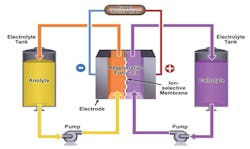

Li-ion batteries are the workhorse technology in today’s energy storage systems, but another energy storage player is making waves: the reduction-oxidation (redox) flow battery. Simply stated, the redox flow battery is a regenerative fuel cell. The electrolyte is stored in external tanks and flows through a membrane. An ion exchange takes place at the membrane, which causes electric current to flow.

Multiple types of flow batteries are available, but vanadium, iron, bromine and sodium are the most popular commercial batteries right now. The technology is ideal for utility-scale batteries, because the available power is determined by the size of the electrochemical cell and the energy is proportional to the size of the electrolyte storage tanks. Flow batteries have a long cycle life and provide fast response times. One of the most positive features of the flow battery is they do not wear out.

VRB Energy announced the first phase of China’s Hubei Zaoyang storage integration demonstration project was commissioned in January 2019. This phase is a 3-MW/12-MWh vanadium redox flow battery storage system, which will have an overall rating of 40 MWh. VRB said the pilot project is being used to demonstrate the use of flow battery storage systems. In addition, a 200-MW/800-MWh vanadium energy storage project is underway in Dalian, China. It is being manufactured by Rongke Power Co. Ltd. and UniEnergy Technologies (UET).

San Diego Gas & Electric Co. (SDG&E) announced the Bonita vanadium redox flow battery storage pilot project in coordination with Sumitomo Electric Industries Ltd. The 2-MW/8-MWh flow battery pilot project is slated to run for four years. SDG&E plans to test the vanadium redox battery for providing voltage frequency, power outage support and shifting energy demand.

Another 2-MW/8-MWh vanadium flow battery was installed on Snohomish County Public Utility District’s network. UET built and installed the battery as well as its control system in 20 connected shipping containers using a molecular breakthrough developed by the Pacific Northwest National Laboratory (PNNL). PNNL found adding hydrochloric acid to the electrolyte solution almost doubled the energy storage capacity and increased its operational temperature range, which reduced the need to maintain temperature control.

Flow batteries also found their way into microgrids, which makes sense because today’s microgrids need longer-duration energy storage. CMI Group announced it had installed an industrial microgrid that integrates a 4.2-MWh energy storage system containing a Li-ion battery and two flow batteries with a 2-MW rooftop photovoltaic system in Seraing, Belgium. BYD Co. Ltd. supplied the Li-ion battery, VIZn Energy Systems supplied a 0.4-MW/1.2-MWh flow battery and Sumitomo supplied a 0.5-MW/1.75-MWh flow battery. Keep watching the flow battery technology. Their prices are coming down, and they typically have a 6-hr to 10-hr capacity compared to a typical Li-ion battery’s 2-hr to 4-hr capacity.

Energy Storage 2.0

Energy storage technology has become critical to the evolution of the grid as the electric utility industry transitions into the 21st century power delivery system. When more renewable resources are added, energy storage is necessary to balance the supply and demand. With the decentralization of the power supply, energy storage improves distributed generation systems. Making the grid more resilient to outside forces requires energy storage to prevent blackouts and reduce outages, but — as more grid applications are explored — there are many expectations about the next big push. Two topics gaining interest are long-duration storage and energy storage as a service (ESaaS).

With all the emphasis on taming wind and solar generation, long-term energy storage is natural. Studies have shown Li-ion battery projects with durations longer than four hours are pushing the technology. Longer-duration technology is available, and the DOE is funding research projects with storage capacities up to 100 days.

Another trend emerging is providing ESaaS, which makes perfect sense with the costs associated with energy storage. In the U.K., Solo Energy Ltd. launched a range of home energy services, including ESaaS. Aggreko has started an ESaaS group to rent energy storage systems with two-year to four-year rental contracts. According to the company, its ESaaS is available globally.

In the utility realm, Green Mountain Power is offering customers a Tesla Powerwall for a small monthly fee. It is reasonable to expect others will follow Green Mountain’s lead.

There is a great deal of speculation as to what energy storage technology will look like in the next five to 10 years. Given what has happened in the past two years to three years, it is impossible to predict, but one thing is for sure: Energy storage 2.0 will be exciting.

For more information:

AEMO | www.aemo.com.au

Aggreko | www.aggreko.com

ALTEO | https://alteo.hu

Bosung Powertec | www.bosungpowertec.co.kr

BYD | www.byd.com

CMI Group | www.cmigroupe.com

Dalian Rongke Power | www.rongkepower.com

Doosan GridTech | www.doosangridtech.com

East Penn Manufacturing | www.eastpennmanufacturing.com

Ecoult | www.ecoult.com

EDF Energy | www.edfenergy.com

Electric Power Research Institute | www.epri.com

Fluence | https://fluenceenergy.com

GE | www.ge.com

Green Mountain Power | https://greenmountainpower.com

Kokam | http://kokam.com/

LADWP | www.ladwp.com

NEC Energy Solutions | www.neces.com

Nidec Industrial Solutions | www.nidec-industrial.com

Northern Drilling | www.northerndrillingltd.com

Origin Energy | www.originenergy.com.au

Panasonic | www.panasonic.com

PNM | www.pnm.com

PNNL | www.pnnl.gov

S&C Electric | www.sandc.com

Sandia National Laboratories | www.sandia.gov

SCE | www.sce.com

SDG&E | www.sdge.com

Siemens AG | www.siemens.com

Solo Energy | https://solo.energy

Sumitomo | https://global-sei.com

Snohomish County Public Utility District | www.snopud.com

ST Engineering | www.stengg.com

Tesla | www.tesla.com

UET | www.uetechnologies.com

Vestas | www.vestas.com

VIZn Energy Systems | www.viznenergy.com

About the Author

Gene Wolf

Technical Editor

Gene Wolf has been designing and building substations and other high technology facilities for over 32 years. He received his BSEE from Wichita State University. He received his MSEE from New Mexico State University. He is a registered professional engineer in the states of California and New Mexico. He started his career as a substation engineer for Kansas Gas and Electric, retired as the Principal Engineer of Stations for Public Service Company of New Mexico recently, and founded Lone Wolf Engineering, LLC an engineering consulting company.

Gene is widely recognized as a technical leader in the electric power industry. Gene is a fellow of the IEEE. He is the former Chairman of the IEEE PES T&D Committee. He has held the position of the Chairman of the HVDC & FACTS Subcommittee and membership in many T&D working groups. Gene is also active in renewable energy. He sponsored the formation of the “Integration of Renewable Energy into the Transmission & Distribution Grids” subcommittee and the “Intelligent Grid Transmission and Distribution” subcommittee within the Transmission and Distribution committee.