A proposed ruling by the Occupational Safety and Health Administration (OSHA) could change the way electric utilities maintain and test their personal protective equipment (PPE) for their workforce.

Updates are now underway for OSHA’s Electric Power Generation, Transmission, and Distribution and Electrical Protective Equipment standard. OSHA began the process in 2003 and issued the notice of proposed rulemaking in 2005. This proposal has been slowly making its way through the rulemaking process, and according to sources in OSHA, it has cleared the final hurdle of approval by the Office of Management and Budget. While OSHA has delayed the final rule announcement, this rule will certainly be published sooner rather than later given its current status along the rulemaking timeline.

Proactive companies have been following the proposed OSHA updates and moving forward with implementation in order to be well positioned once the changes take place. Not only will this place them in a position of immediate compliance, but it also keeps them on the leading edge of safety.

Testing PPE

This rulemaking update for the Electrical Protective Equipment standard includes both the OSHA General Industry Codes of Federal Regulation as well as creating an entirely new section in the OSHA Construction Codes of Federal Regulation. Historically regarding PPE, OSHA frequently makes reference to specific consensus standards including the date of the edition of these standards. OSHA cannot require compliance with future editions that have yet to be published.

Since all consensus standards are typically updated every couple of years — whereas OSHA standards are updated much more infrequently — OSHA wanted to ensure that the in-service care and use of electrical PPE was reflective of the most updated and latest ASTM consensus standards.

Instead of referencing specific ASTM standards, which would have to include the date of a specific edition of the standard(s) to be complied with, as it has historically done, OSHA is taking a new approach in its regulatory language. In an unprecedented effort to affect compliance with the latest edition of these continually changing ASTM consensus standards, OSHA is using a performance-oriented requirement. Specifically, it states that “whatever test is used must reliably indicate that the equipment can withstand the proof-test voltage involved.” This would place the burden of proof on the employer to establish that reliability. Utilities could meet this requirement by following the most recent ASTM standards regarding the in-service care and use, including the proof testing of electrical PPE rubber goods like gloves, sleeves and blankets. This testing reliability also would presumably extend to the quality and accuracy of the testing.

Finding a Testing Lab

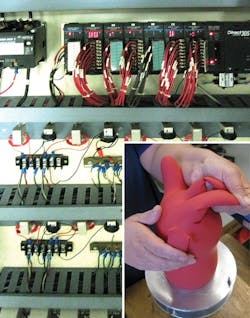

Reputable testing laboratories proactively update their protocols to conform with the latest editions of these ASTM testing standards. Additionally, they have laboratory certification to further ensure the accuracy and quality of their testing protocols.

Both employers whose employees use electrical PPE and now many utilities are sending their rubber goods to testing labs for the required periodic electrical proof testing. It is becoming imperative that companies know more about their test lab because the burden of proof for regulatory purposes now rests with the employer.

The Association of North American Independent Laboratories for Protective Equipment Testing has stringent requirements for accreditation and certification. NAIL for PET Accredited Rubber Goods Testing Labs, such as Hi-Line Utility Supply, have to undergo an extensive certification process on criteria such as the expertise of the staff, lab practices and equipment calibration. Equipment maintenance, including traceability to the National Institute of Standards and Technology, is combined with periodic site visits for verification.

How well you know your test lab may affect the safety of your workers as well as your regulatory compliance vulnerability. This new OSHA requirement will change the way you look at your electrical testing lab. By implementing the new requirements early, you will be positioned for safety and compliance when the changes go into effect.

John “Grizzy” Grzywacz is a professor emeritus at the Occupational Safety and Health Administration National Training Institute. For more than two decades, he has trained OSHA compliance officers in electrical safety standards, power generation transmission and distribution, and machine and machinery safeguarding. He continues to train OSHA compliance officers and personnel, and provides investigative assistance to OSHA on fatality investigations and significant cases.

Companies mentioned:

Hi-Line Utility Supply | www.hilineco.com

OSHA | www.osha.gov

Sidebar: Questions to Ask Your Testing Lab

1. Are you testing rubber goods to the latest edition of the

ASTM standards?

2. Are you certified and accredited?

3. How do you maintain compliance with ASTM and OSHA

standards?

4. Can I tour your lab to learn more about how you operate

and how you test your rubber goods?