As electric transmission networks become more interconnected and more power generating plants are added, the available fault current level continues to increase. In some parts of the North American electric system, the magnitude of available fault current is at the interrupting rating limit of commercially available circuit breakers. If a circuit breaker is incapable of interrupting the fault, severe and costly damage to equipment may occur as well as substantial customer outages.

When the available fault current nears or exceeds the capability of a circuit breaker, utilities typically resort to upgrading equipment. When upgrading equipment is not possible — because of a lack of existing circuit breakers capable of interrupting the available fault current — utilities traditionally implement split substation buses or add impedances to transmission lines (that is, install current limiting reactors). Central Hudson Gas & Electric Corp. is testing a new superconducting fault current limiter (SCFCL) that may eliminate potential damage to critical infrastructure and possibly improve grid efficiency in some applications.

Traditional Solutions

Traditional approaches to limiting fault currents can be complex and expensive. The substantial additional physical space required can increase costs further, especially in urban locations where more space can be difficult to obtain. Furthermore, traditional approaches can reduce the reliability of the electric network, curtail disaster-recovery capability, impose severe operational constraints, and impact efficiency through increased real and reactive electric losses.

For example, adding current limiting reactors to a system to control fault currents can degrade voltage regulation for all customers served by the bus. The added reactance also can cause phase shifts, reduce transmission efficiency and potentially contribute to system stability issues. Furthermore, the threat of voltage dips during faults and their potential operational impact can raise concerns among some larger customers, potentially leading to installation of duplicate services to enhance reliability. However, this is a costly solution that can create other challenges.

New Superconducting Solution

The potential destructive impacts of high fault currents are why Central Hudson was interested in learning more when approached by Applied Materials Inc. with an opportunity to partner on a proposal to deploy and test a new superconductor-based fault-mitigation system. In addition to eliminating potential damage to critical infrastructure, there is the added possibility this technology could improve grid efficiency in some applications.

The SCFCL was developed and manufactured by Applied Materials. The system was installed and commissioned on June 16, 2014, at Central Hudson’s Knapps Corners substation in the Town of Poughkeepsie, New York, U.S., as a research and development project funded in part by a successful bid for support from the New York State Energy Research and Development Authority (NYSERDA).

The SCFCL was installed in parallel with a conventional fault current limiting reactor to ensure testing could be conducted with minimal risk. In theory, the SCFCL working in conjunction with the fault current limiting reactor would limit a fault’s overall current to a desired level with minimal impact to system efficiency. Central Hudson would benefit from an evaluation of a technology with potential future applications on its system, and Applied Materials would be able to evaluate the SCFCL in a real-world situation.

Superconductors today offer a robust approach to controlling fault current levels on utility distribution and transmission networks, particularly at higher voltage levels. The remarkable thing about superconductors is they operate with low impedance and are essentially invisible electrically. However, in the event of a fault, a SCFCL can rapidly (almost instantly) add impedance to the circuit, limiting the fault current and simultaneously providing the utility with a low-impedance, stiff system as well as a low fault current level.

This provides an obvious breakthrough for system designers by offering impedance that varies almost immediately with operating conditions. These characteristics are inherent to the superconducting material itself; the superconductor responds to the current and no external trigger is required.

The operation of Applied Materials’ SCFCL relies on the physical properties of the superconducting material. In normal operation, current passes through a matrix of superconducting tape, its length determined by the required current and voltage of the specific installation. The superconducting tape is immersed in liquid nitrogen, rendering a near-zero impedance to current flow. The physical nature of superconductors is such that they become highly resistive when the current flowing through them exceeds a maximum level determined by the chemical composition of the material and the length and composite width of the tape in the matrix.

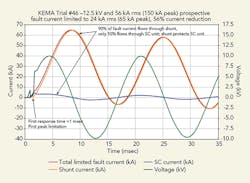

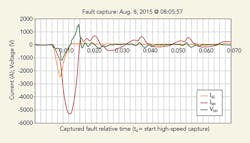

If a fault current occurs and exceeds the current level at which the SCFCL is designed to superconduct (that is, the quench level), the superconductor becomes highly resistive within the first-quarter cycle of the 60-Hz signal (4 msec), forcing a majority of the current into a parallel current limiting reactor that will limit the current flow. Once the fault is isolated, the superconducting material will reacquire its near-zero impedance, thereby bypassing the current limiting reactor. The system naturally resets itself and becomes transparent, without intervention, until the next fault event occurs.

The Knapps Corners Test

The Knapps Corners substation was chosen as the in-service testing location for the device, because it represented a low-risk yet challenging test opportunity for Central Hudson and would provide the required performance data for Applied Materials. Available fault current on the distribution bus was running well above the utility’s target of less than 8 kA, typically around 12 kA. To address this condition, Central Hudson was planning to install current limiting reactors between each transformer neutral and ground (which also would lead to a voltage rise from ground to each transformer neutral when current flowed).

As part of its validation process, Applied Materials responded to the NYSERDA competitive solicitation to demonstrate the superconducting fault current limiter technology with Central Hudson as the utility partner. Two additional organizations eventually became partners in the program: SuperPower Inc., the developer and producer of second-generation high-temperature superconducting (2G HTS) wire used in the system, and Three-C Electrical Co., a utility systems design and integration consultant.

With funding and project support from NYSERDA, Central Hudson and Applied Materials moved forward with a plan to engineer and install an SCFCL unit in parallel with the current limiting reactors already scheduled for the Knapps Corners substation, with the goal of testing this new technology.

System testing and evaluation is ongoing and expected to continue through at least August 2016. Performance data will be provided to NYSERDA.

Promising Early Results

The Knapps Corners SCFCL is currently the longest continually functioning SCFCL in service in North America. To date, the SCFCL system in Poughkeepsie has operated through six full seasons and under a variety of environmental conditions, including extreme temperatures and heavy snow. The system has performed as expected and successfully limited current associated with 22 faults that could have contributed to equipment damage or failure.

The number of successful operations by the SCFCL at the Knapps Corners substation has reduced the stresses placed on substation and distribution equipment during faults. Central Hudson is encouraged by these results and looks forward to the potential for future applications of this promising technology.

Richard B. Wright is senior engineer in electric transmission planning for Central Hudson Gas & Electric Corp., with more than 30 years of experience in power systems with Central Hudson. He holds a BSECE degree from Clarkson University, a M.Eng. degree in electric power engineering from Rensselaer Polytechnic Institute and an engineer’s degree in electrical engineering from Polytechnic University. He is a professional engineer.

Sidebar: NYSERDA Support

The New York State Energy Research and Development Authority (NYSERDA) promotes energy efficiency and greater use of renewable energy sources to help achieve New York’s State Energy Plan goals:

• Reduce greenhouse gas emissions by 40% by the year 2030 and 80% by 2050

• Generate 50% of electricity from renewable energy sources

• Decrease energy consumption in buildings by 23% by 2030.

NYSERDA works with numerous stakeholders across New York — including residents, businesses, community and government leaders, and researchers — to develop and implement innovative energy solutions, attract private sector investment to expand New York’s clean energy economy and enable New Yorkers to benefit from energy efficiency and renewable energy.

NYSERDA provided support for the Central Hudson Gas & Electric Corp. project through the smart grid program, a 10-year, $40 million state research and development incentive program that has helped bring more than 80 projects to fruition. This project advances New York Gov. Andrew Cuomo’s Reforming the Energy Vision strategy to build a clean, resilient and more affordable energy system for all New Yorkers.

Sidebar: Idealized Version

To better understand the characteristics of a fault current limiting (FCL) device, it is good to start with an idealized version of the FCL. When integrated into the grid, the ideal FCL is invisible to the operation of the grid under normal conditions — it has no impedance or voltage drop, gives off no harmonics and overall is completely benign to the operation of the grid.

When a fault occurs, the FCL transforms itself from a transparent state into a high-impedance state during the initial rise of the fault. Before the first peak is reached, the FCL will do the following:

- Ensure a required amount of let-through current is maintained to make sure protection system fault detection

- Transform into (insert into the grid) a known impedance specifically calculated for each site application to reduce the fault level by a required amount

- Reduce the first peak of the fault as well as subsequent peaks

- Remain in the high-impedance state until the fault is cleared and the grid resumes normal operation.

After the fault is cleared, the FCL will self-heal and return automatically to its transparent state.