Climate change typically means warmer weather, but grid operators also are experiencing more extreme cold spells. These colder temperatures are a common hesitancy for wider adoption of electrification — whether that be electric vehicles (EVs), drones or other field operations equipment.

Despite the colder temperatures, interest in EVs is increasing rapidly in Alaska. Because EVs interact directly with electrical generation systems — distributed and community — and have the potential to act as dispatchable loads or storage to support electric grid stability, the Alaska Center for Energy and Power (ACEP) at the University of Alaska Fairbanks (UAF) is investigating research questions pertinent to EVs in Alaska.

Cold Region Research

As early as 2009, a research team at the UAF Transportation Center began studying EVs in Alaska. Although the technology was in a very different state at that time (vehicles were either self-built or conversions), the research team’s Feasibility Study of Electric Cars in Cold Regions report noted: “Electric vehicles can be a viable option for certain users in the subarctic and arctic communities.”

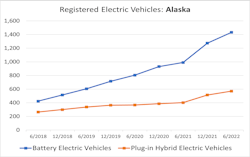

Since then, the state has had a large uptake of plug-in EVs in Southeast Alaska, where hydroelectric power enables low costs, the limited size of road systems largely negates driving range anxiety, the climate is relatively temperate and consumers can directly access used EVs from the Lower 48 by ferry.

Every six months, the member-owned Chugach Electric Association (CEA) conducts a count of EVs registered in Alaska. The number of registered EVs in Alaska, and the municipality of Anchorage in particular, has risen steadily in recent years. CEA’s report tallies two types of EVs that charge from the electric grid: battery electric vehicles (BEVs) that run solely on electricity stored in batteries, commonly with a range of 200 miles to 300 miles or more (322 km to 483 km), and plug-in hybrid electric vehicles (PHEVs) that typically have a more limited all-electric range, often 25 miles to 40 miles (40 km to 64 km), before switching over to an internal combustion drivetrain.

Interactive EV Temperature Map

In 2020, ACEP worked with the University of Washington’s Data Intensive Research Enabling Clean Technologies (DIRECT) program to gather EV and temperature data into a set of metrics. This work led to the publication of an online EV temperature map that shows three metrics related to temperature effects on performance. Users of the interactive global map can see how EVs may perform in their locale, which helps to address temperature uncertainties.

These metrics can be used to help predict performance and efficiency or inform EV strategies in different regions of the world. Looking at the EV scores, much of China, Russia, Europe, Iceland, Greenland, Canada, the northern U.S. and mountainous regions of the world have scores overlapping with those of Alaska.

Cold-Weather Effects

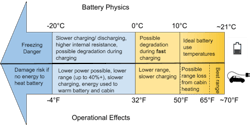

Broadly speaking, cold temperatures can have two negative consequences on EVs: reductions in operational performance and battery degradation. Operational performance issues include a diminished driving range caused by the battery, cabin and other heating loads as well as lower energy and power available from cold batteries. In addition to cold-weather issues that are unique to EVs, reductions in operational performance can be caused by traction and other environmental conditions that affect all vehicles. On the other hand, battery degradation occurs when cold temperatures damage an EV battery, which can shorten a vehicle’s life span.

The cold-weather performance of different EV models may vary because battery technologies, battery heating and management systems, and cabin heating technologies sometimes differ. However, many of the proprietary details for commercially available models are not public knowledge.

Managing The Effects

To manage cold-weather effects on batteries, an operational strategy such as a battery thermal management system (BTMS) is used that allows battery heating to maintain an optimal temperature range. When EVs are not plugged in to an external power source, they must power the BTMS from the battery itself, although some vehicles do not power the BTMS unless it is plugged in.

Any solution must balance the cost and other trade-offs between reduced battery health (and thus life) and the cost of the system to heat the battery. BTMS costs accrue from the complexity and extra weight of components, the cost of electricity and reduced battery cycle life. One study, Thermal Management of a Hybrid Electric Vehicle in Cold Weather, concluded parking outside at work or overnight without plugging in are issues with the actual BTMS strategies of common EVs and hybrid EVs — mainly because aging (incremental degradation of the energy capacity of the battery) as a result of cold temperatures is not considered in the development of the BTMS.

A study on “Battery Warm-Up Methodologies at Subzero Temperatures for Automotive Applications,” published in the March 2020 issue of Progress in Energy and Combustion Science, provided a review of literature published about battery heating research, finding there are two primary battery heating strategies:

- In the first strategy, an external source transfers heat to the battery convectively or conductively. Convective options include air, liquid and heat-pump heating, whereas conductive options include resistance, Peltier-effect, heat pipe, phase change materials and burner heating.

- In the second strategy, internal resistance is generated from a current applied to the battery itself, thereby heating the battery from the inside. The self-heating Lithium-ion battery (SHLB) is one recent example of this technology.

Both strategies have their weaknesses. On the one hand, external heat sources result in longer warm-up times, less temperature uniformity (which affects battery performance and health) and more energy consumption. On the other hand, internal heating must be designed carefully to use current levels and durations that do not cause excessive damage and, therefore, are harder to implement.

Battery Heating Energy Costs

According to lab testing, an external heating source for an EV BTMS generally requires less energy than an engine block heater for an internal combustion engine (ICE).

Of the lab-tested external heating options reviewed in the Battery Warm-Up Methodologies at Subzero Temperatures for Automotive Applications study, most options required no more than 40 W in 35 minutes to heat the batteries by 20°C to 40°C (68°F to 104°F) in temperatures as low as –25°C (–13°F). EV batteries must be maintained above –20°C (–4°F) to prevent permanent degradation, and consumer acceptance may be greater for a vehicle that is always ready to drive without having to wait to warm the battery. This expectation may necessitate continual heating throughout the day, instead of a single heating event before driving.

In a real-world setting, energy use data logged by CEA for its Chevrolet Bolt while plugged in outdoors overnight in Anchorage, Alaska, indicated the car drew an average of about 500 W at –18°C (0°F). The energy consumption of a BTMS is expected to be even greater in colder temperatures.

By comparison, most ICE block heaters require 400 W to 750 W and are recommended to be plugged in for 2 hours at –7°C (20°F) and 4 hours when temperatures are below –20°C (–4°F), as summarized by Manitoba Hydro in an overview on its Power Smart residential program. Despite these recommendations, many people plug in car block heaters (often in conjunction with battery blankets and oil pan heaters) at home and at work continuously during extremely low temperatures. ICEs generally do not suffer permanent damage if stored unheated in extreme cold, except perhaps to the starter battery, which can be brought indoors.

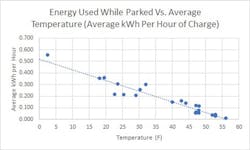

Energy costs for battery heating strategies can be extrapolated from real-world data. In Anchorage, Alaska, energy use for CEA’s Chevrolet Bolt was logged when fully charged and plugged in outdoors overnight. In looking at the data, heating energy use is approximately linear with temperature, at least between about –18°C (0°F) and 13°C (55°F). Parking this EV outdoors in Anchorage for 11 hours at about –7°C (20°F) costs roughly $0.75, with electricity priced at $0.20/kWh. For comparison, it

is estimated the cost of cold-starting a gas engine is $0.30/day.

A 400-W engine block heater plugged in at –7°C (20°F) for 2 hours would cost $0.16. This is about an extra $0.60 for the EV overnight.

If the trend stays linear, this means about $0.87 to $1.01 kWh/hr average use while parked fully charged at –40°C (–40°F). For a full 24 hours, this is about 24 kWh, or $4.80 total to keep warm. A block heater plugged in for 24 hours would have to draw more than 1000 W of power to be more expensive. This impacts the economics of fueling an EV in extremely cold climates. The data currently available for energy used while parked and driving are incorporated into an online calculator for Alaskans to investigate the cost and emissions of an EV vs. an ICE.

Future Research

Given the performance of today’s commercially available EVs in extreme cold temperatures, there is a need for better battery thermal management or cabin heating strategies for cold regions. Opportunities for further research include the following:

- Test self-heating batteries.

- Collect and analyze data on power draw vs. temperature for different EV models while charging and while fully charged.

- Test levels one, two and three nominal charging speeds vs. temperature.

- Collect and analyze data on maximum range and energy use per mile vs. temperature for different EV models.

- Evaluate the change in maximum range over time (years) for several EV models parked outside in ambient air temperatures.

- Investigate the effects of extreme cold on EVs parked in ambient air temperatures but not plugged in (for example, minimum starting temperature, loss in battery state of charge with time and battery recovery when brought back into a warm environment). Testing to the point of significant damage or failure (that is, partial or total loss of battery capacity) would provide useful information yet would also incur substantial expenses.

- Develop a workable electric all-terrain vehicle and snow machine for rural Alaska using Lithium-titanate batteries for their cold performance.

- Investigate secondary, external and portable cabin heat sources that could alleviate the draw on the main battery for heating (for example, heat packs).

Michelle Wilber is a research engineer at Alaska Center for Energy and Power (ACEP), University of Alaska Fairbanks, where she works on projects ranging from investigating solar energy potential in Alaska to analyzing electric vehicle energy use in the state.Wilber has a bachelor’s degree in astronomy from the California Institute of Technology and a MSME degree from the University of Alaska Anchorage. She has worked as an engineering geologist, as an organic gardening coordinator, in energy-efficiency outreach, and as a park ranger in Katmai National Park and Preserve.

About the Author

Michelle Wilber

Michelle Wilber is a research engineer at Alaska Center for Energy and Power (ACEP), University of Alaska Fairbanks, where she works on projects ranging from investigating solar energy potential in Alaska to analyzing electric vehicle energy use in the state. Wilber has a bachelor’s degree in astronomy from the California Institute of Technology and a MSME degree from the University of Alaska Anchorage. She has worked as an engineering geologist, as an organic gardening coordinator, in energy-efficiency outreach, and as a park ranger in Katmai National Park and Preserve. All of Wilber’s education and work experiences come together in solving the problems of finding sustainable energy sources in the Arctic.