It should be simple to decarbonize the power grid, so why isn’t it? It turns out there are always speedbumps in every endeavor that were not fully anticipated and the transition to clean power has several. One that has been catching attention is associated with the pace of renewable generation deployment. Another is the speediness of fossil-fuel power plants retirement. Both of these events set in motion another snag, the significant decline in system inertia.

Inertia is the kinetic energy produced by a rotating mass like the armature of a generator. This spinning mass resists change and acts like a buffer. Power engineers refer to it as grid inertia, which allows the grid to ride through disturbances. Think of those times when a momentary loss of power causes the lights to blink. Without inertia those lights will stay off.

If it’s that important why not leave well enough alone as the old saying goes? Once again, it’s not that simple. The energy sector is responsible for 31% of CO2 emissions produced in the U.S. according to the U.S. Energy Information Administration (EIA), These are greenhouse gasses. They are directly linked to global climate change and all the extreme weather events that have been playing havoc with the power system.

Fossil Fuel and Climate Change

The biggest producers of those CO2 emissions in the energy sector are fossil-fueled power plants. That brings us back to the decarbonization of the power grid with clean energy sources, and transitioning away from fossil-fuel. Worldwide, it’s a mixed bag as far as who is retiring what and when. In the U.S., however, coal-fired generation retirement has really been accelerating with the influence of the Inflation Reduction Act.

Based on the latest available data, the Institute for Energy Economics and Financial Analysis (IEEFA) is projecting the U.S. will have cut its peak coal use from 318 gigawatts (GWs) in 2011 to roughly 159 GWs, about 50%, by 2026. IEEFA estimates U.S. total coal-fired generation will drop to around 116 GWs by 2030 if all of the announced retirements and conversions take place. That’s about 36% of the 2011 peak capacity.

Getting back to inertia, the fossil-fuel generation is being replaced by inverter-based devices (e.g., wind, solar, batteries, etc.), which adds to the complexity. Inverter-based devices use grid-following and grid-forming technologies to turn their direct current outputs into alternating current for use on the power grid.

Grid-following inverters are well established, but they tend to trip during any grid disturbance and cannot be reconnect to an unstable grid. On the other hand, grid-forming inverters can address these stability issues by adding what is called virtual inertia, but the technology has its limitations. Despite being introduced in the early 2000s, they are still considered an emerging technology, and their use is not as widespread as grid-following inverters.

DOE (Department of Energy) says it best, “As wind and solar account for increasing shares of overall electricity supply, it’s becoming impractical to depend on the rest of the grid to manage disturbances.” One solution would be to replace all the grid-following inverters, but that is unacceptable due to the costs involved. Once again, there is a technology that addresses the issue: the synchronous condenser.

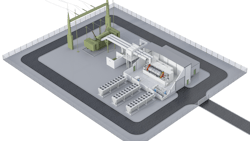

Keeping it simple, a synchronous condenser is a synchronous generator that can be coupled with a flywheel to add extra capacity. It’s powered by a variable-speed motor and connected to the transmission grid through a step-up transformer. When the rotating mass reaches synchronous speed (grid frequency), it’s synchronized with the transmission system. At that point, the synchronous condenser provides inertia along with short-current power, voltage support, and generating/absorbing reactive power.

Hybridizing Stabilization

Synchronous condensers aren’t new, but their abilities took a quantum leap when modern digital controls and sophisticated software were integrated into them. There has also been the development of the hybrid synchronous condenser application. This modernization makes synchronous condensers a valuable addition to the FACTS (flexible AC transmission systems) controller family, and this is where it gets a little complicated so it’s time to speak with an expert.

“Charging Ahead” contacted Ralph Morgenstern, senior sales manager FACTS at Siemens Energy to talk about synchronous condensers and some unique applications Siemens Energy is taking part in. Mr. Morgenstern began saying, “System inertia has been steadily declining on the world’s electric power grids as large-scale, centralized fossil-fuel based power plants are being phased out in favor of renewables. A good example of this is taking place in Ireland, where coal-fired power generation is being phased out and replaced by a lot of wind energy. To make matters more complicated, Ireland is physically and electrically an island.”

Morgenstern continued, “Until now Ireland has had two HVDC interconnections to Great Britain: the East West interconnection and the Moyle interconnection. Currently two more HVDC interconnections are being built; the Greenlink interconnector to Great Britian and the Celtic interconnector to France and that helps. Additionally, Ireland’s ESB (Electric Supply Board) energy company is repurposing their Moneypoint coal-fired power station on the Irish Mid-West coast into Ireland’s first green energy production hub. That’s why inertia is important. The first step before retiring the Moneypoint power plant was the installation of a state-of-the-art synchronous condenser connected to the world’s largest flywheel. The flywheel rotor weighs over 130 tons and the synchronous condenser’s rotor weighs over 66 tons. Together they deliver around 4,000 megawatt-seconds of inertia capability. The large flywheel has increased the inertia capability of the synchronous condenser at Moneypoint, but there is more to this story.”

Morgenstern explained, “Siemens Energy has developed a hybrid grid stabilization system utilizing the proven synchronous condenser plus large flywheel technology combined with a large-scale BESS technology. The hybrid grid stabilization system will be installed in the Irish grid at Shannonbridge in County Offaly, Ireland. The Shannonbridge’s hybrid project provides 4,000 megawatt-seconds of inertia capability combined with the 160 megawatt-hour battery energy storage system (BESS). Completing the package are energy conversion systems, a control system, and the necessary medium voltage equipment. The Shannonbridge installation is the first time these technologies have been connected to the transmission grid in a single connection and work has already begun at the site.”

According to Mr. Morgenstern, “Ireland also has market mechanisms in place that allows operators to sell services such as inertia, short-circuit power and reactive power as provided by the synchronous condenser technology. Siemens Energy supports this by providing an energy management system that allows the owner to respond to market demands and power needs in real-time.”

Applying Inertia to the Grid

The synchronous condenser has definitely moved from a specialty item to being a feature player for adding renewables to the grid. Global Market Insights reports, “The increasing demand for a reliable and consistent power supply has led to the recognition of synchronous condensers as the preferred solution for grid resilience.” They also noted that the global synchronous condenser market exceeded US$ 1.3 billion in 2022, and estimates the market will continue at a 4.8% CAGR (compound annual growth rate) through 2032.

In 2023, ERCOT (Electric Reliability Council of Texas) finalized their study, “Assessment of Synchronous Condensers to Strength West Texas System.” ERCOT projected the total capacity of inverter-based resources (wind, solar, and energy storage) in West Texas will exceed 42 GWs by 2025. The study also revealed there were significant stability risks due to system disturbances. ERCOT identified the West Texas system needed six new 350 MVAr (megavolt amperes reactive) synchronous condensers on the 345 kilovolt system. Each installation will have a total inertia capacity of approximately 2,000 megawatt-seconds, which means a possibility of using a flywheel coupled option. The in-service date would be late 2027.

Also, Estonia, Latvia, and Lithuania are leaving the Russian electric system and will be connecting their transmission systems to Continental Europe’s network by 2025. Studies indicate that synchronous condensers are needed to make this happen. These Baltic countries have formed the Baltic power grid synchronization project, which will install three synchronous condensers in each country. The first synchronous condenser in the series was commissioned by Elering, the Estonian system operator, last year in Püssi, Estonia. These synchronous condensers will supply inertia to regulate the frequency of the network. They will also provide sufficient short-circuit current for proper protection and automatic operation.

These are a few examples of the projects utilizing synchronous condensers on transmission systems around the world. The global market for these applications is expanding and it’s not just taking place on the utility’s side of the meter. Industry found them valuable for power factor correction and VAR compensation to name a few applications, but the real value comes from the decline of large fossil-fuel fired power plants. This lost inertia is critical to the grid’s stability and resilience. Adding technologies like flywheels, large-scale BESS, and energy management systems increases their effectiveness beyond traditional synchronous condensers. Hybrid synchronous condensers offer the flexibility needed for grid stability and the buffer needed for the rapid shift to renewables!

About the Author

Gene Wolf

Technical Editor

Gene Wolf has been designing and building substations and other high technology facilities for over 32 years. He received his BSEE from Wichita State University. He received his MSEE from New Mexico State University. He is a registered professional engineer in the states of California and New Mexico. He started his career as a substation engineer for Kansas Gas and Electric, retired as the Principal Engineer of Stations for Public Service Company of New Mexico recently, and founded Lone Wolf Engineering, LLC an engineering consulting company.

Gene is widely recognized as a technical leader in the electric power industry. Gene is a fellow of the IEEE. He is the former Chairman of the IEEE PES T&D Committee. He has held the position of the Chairman of the HVDC & FACTS Subcommittee and membership in many T&D working groups. Gene is also active in renewable energy. He sponsored the formation of the “Integration of Renewable Energy into the Transmission & Distribution Grids” subcommittee and the “Intelligent Grid Transmission and Distribution” subcommittee within the Transmission and Distribution committee.