Helping the UK Power Grid Spin Back its System Inertia

National Grid Electricity System Operator (NGESO), the operator of the Great Britain electricity system is focused diligently on a target — to be able to operate a zero-carbon electricity grid by 2025. This is sparking a transformation of the British electricity system that is being watched with interest by system operators and manufacturers around the world.

As more renewable energy sources are connected to the electricity system and renewable energy generation increases, new ways to maintain system stability are required. This vital transition from large fossil-fuel plants to renewable energy generation presents a need for innovative solutions that can maintain system stability, increase the amount of renewable energy delivered via the grid network, and reduce costs for consumers.

Inertia provides a response that is temporary and is typically available for only a few seconds. That allows the power grid to ride though short duration faults. This keeps system frequency within controlled limits of around 50 Hz. In an intact, stable system, the frequency of electricity across the power system remains the same and can react to any loss of load or generation due and is robust against disturbances.

In its operability strategy report published in December 2022, National Grid said that its current policy was to ensure that system inertia was always above 140 GJ. However, it notes that, by 2025, its ambition is to maintain a minimum system inertia of 96 GJ.

Providing Stability Services

In January 2020, NGESO announced the results for its first Stability Pathfinder approach to managing the stability of the British power grid. Contracts were agreed with five parties (including Statkraft), worth around $400 million over a six-year period, to either build new or modify existing assets to provide the vital stability services. The key service to be provided by Phase 1 is inertia, but without delivering any extra electricity on to the grid. This will, therefore, allow more renewable generation to operate and ensure system stability at lower costs.

In total, the contracts for Phase 1 are procuring 12.5 GJ of inertia. That is equivalent to the inertia provided by about five coal-fired power stations. It was estimated at the time that this approach would save consumers up to $158 million over the six-year period. However, with the surge of gas prices in 2022, it is likely that it will result in much more than this.

As electricity needs are increasingly for energy generated from renewable sources, there will be longer periods where there will be no need for fossil fuel generation and, therefore, additional stability services will be required by projects such as the Lister Drive Greener Grid Park. On April 20, 2020, NGESO had to request generation from 17 gas-fired power plants simply for their stability services, increasing carbon emissions and consumer costs.

Greener Grid Parks

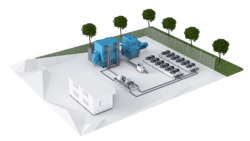

Statkraft is contributing to the Stability Pathfinder initiative through its Greener Grid Parks. One of these is now operational in Moray, Scotland, while the other site that houses two of ABB’s high-inertia synchronous condensers is Lister Drive, recently commissioned in Liverpool, England. Statkraft is progressing several more potential projects across England, Scotland and Wales.

Synchronous Condensers

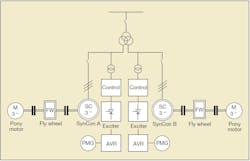

A synchronous condenser is a synchronous machine that is similar in design to a large motor or generator. However, in this context, it is not a motor, as it does not drive anything. Equally, it is not a generator as it does not have a prime mover. However, the condenser draws a small amount of power from the transmission system to supply its inherent losses used keep the condenser rotating.

Synchronous condensers contribute to stable power systems in three main ways:

Inertia support for frequency stability — There is an increasing level of asynchronous resource being connected to the electricity system. These include interconnectors, wind, solar, tidal and battery energy storage systems (BESS). Condensers have a large rotating mass that provides inertia. They can help by damping frequency deviations, which gives both automatic frequency response plant and manual system operators more time to respond to frequency changes.

Fault level contribution — In the event of a transmission system fault, asynchronous technologies provide less fault current than synchronous technologies. This is because asynchronous plant with power electronics controls its fault current capability to a level close to the nominal current. However, a synchronous condenser has an innate fault current response defined by its electrical parameters. The result is that the delivered fault current can be high in amplitude, possibly even five times the nominal current or higher.

Voltage regulation — Like other synchronous and asynchronous technologies, a synchronous condenser can deliver megavolt amperes reactive (MVAr) for voltage regulation. In an under-voltage condition, where the voltage is becoming too low, reactive power is exported to support the system voltage. Equally, in an over-voltage condition, where the voltage is becoming too high, reactive power can be imported.

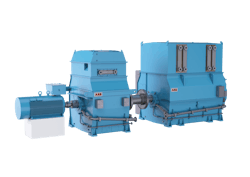

Capacity and Construction

Typical synchronous condensers have been manufactured with ratings of around 80 MVAr with a 10-20 kV machine voltage. The selected voltage is a matter of optimization as a step-up transformer is often used to suit the usually much higher connection voltage. Several condenser units can be connected to achieve higher outputs. This approach offers better redundancy and system availability than installing a single large unit.

The construction of the ABB - synchronous condenser is quite similar to a synchronous generator. It features a salient pole

rotor, brushless excitation and epoxy resin insulated stator windings. The machine is water-cooled, but other options such as air cooling and hydrogen cooling are also possible.

High-Inertia Solutions

Lister Drive Greener Grid Park is ABB’s first project to feature a high-inertia condenser configuration. This approach couples

a 67 MVAr condenser with a 40-ton flywheel.

Combining a mid-size synchronous condenser with a flywheel has the important advantage of multiplying the available inertia by several times. At the same time, the losses may be lower compared to installing the whole inertia as a synchoronous condenser. It is also a cost-effective way of using two mid-sized condensers together with the benefits of a high level of redundancy, increased inertia and greater controllability.

Together, the two units at the Lister Drive Greener Grid Park in Liverpool will provide a total of more than 900 MW-seconds inertia. That means Lister Drive will provide about 1% of the UK’s projected minimum total inertia requirement for 2025. The condensers were commissioned in March 2023.

A Green Solution

Renewable energy continues to make rapid progress in the UK and this success has created some challenges for the power system. On occasions it has been necessary to shut down wind farms and start up gas power plants to keep the system stable. Synchronous condensers promise to make this a thing of the past by maintaining stability without consuming fossil fuels.

Located at strategic points on the grid network, condensers will be able to help prevent power outages, ensure stability and most importantly reduce greenhouse gas emissions from electricity generation with associated cost reductions for consumers.

The UK’s transition to 100% zero carbon electricity and the consequent decommissioning of large synchronous generating plants powered by fossil fuel has resulted in the need for innovative solutions to deliver system inertia vital for system stability. Statkraft’s Greener Grid Park Project in Liverpool is using ABB synchronous condensers that will help to restore this balance.

Guy Nicholson ([email protected]) is responsible for grid integration at Statkraft in the UK. Statkraft is an international hydropower company and Europe’s largest generator of renewable energy. Statkraft has 5,300 employees in 21 countries and is at the heart of the UK’s energy transition. Since 2006, Statkraft has gone from strength to strength in the UK, building experience across wind, solar, hydro, storage, grid stability, EV charging, green hydrogen and a thriving markets business.

About the Author

Guy Nicholson

Guy Nicholson ([email protected]) is responsible for grid integration at Statkraft in the UK. Statkraft is a leading company in hydropower internationally and Europe’s largest generator of renewable energy. Statkraft has 5,000 employees in 19 countries and is at the heart of the UK’s energy transition. Since 2006, Statkraft has gone from strength to strength in the UK, building experience across wind, solar, hydro, storage, grid stability, EV charging, green hydrogen and a thriving markets business.