Countless issues can impact the success and cost efficiency of utility vegetation management programs from one year to the next, and few issues loom as large as the presence of incompatible trees and brush species throughout utility right-of-way (ROW) corridors.

This problematic vegetation poses a threat to interfere with overhead powerlines, leading vegetation managers to employ a number of vegetation control strategies that can protect the integrity of utility infrastructure. However, there are distinct differences between each of these strategies, and skilled labor requirements can be significantly impacted by those discrepancies.

Put simply, labor costs money. And the more it’s needed, the more resources it will drain from annual budgets, which are already tight for most vegetation management programs. Mechanized mowing may be a popular solution for vegetation managers working to keep ROW corridors clear of problematic plants, but this strategy can be particularly costly from a labor perspective. The following details how this particular treatment method can increase labor costs for utility companies and their vegetation management partners:

1. Mechanical Mowing Stimulates Regrowth

As a nonselective treatment method, mechanized mowing controls all vegetation in its path. While this may seem like a good thing, it only creates more treatment requirements down the line. That’s because mowing spreads viable seeds for incompatible vegetation and fails to control the entirety of targeted plants.

As long as there are roots absorbing water and nutrients, most plants are likely to reestablish at full strength. To make matters worse, the spread of viable seeds only increases incompatible stem counts and maintenance requirements over time.

2. Mechanical Mowing Can Require Multiple Passes

Equipment used for mechanical brush control is often designed to remove the top growth of targeted plants. This can lead to resprouting and may even require vegetation managers to mow certain areas multiple times in a short period of time. With some utilities managing thousands of ROW acres each year, these re-treatment requirements can significantly impede annual productivity and the ability to keep vegetation under control in all necessary areas.

3. Mowing Equipment Takes Longer Than Other Methods

Another downfall of mechanical mowing is the amount of time it takes to complete. Research conducted by Asplundh Tree Expert on 2.5- to 3-acre test plots shows that mechanical mowing equipment covered just 0.51 acre per hour (ac/h) while several herbicide applications allowed crews to improve their productivity: Low-volume basal (0.62 ac/h) and high-volume foliar treatments (0.7 ac/h to 3.06 ac/h) used as part of the Asplundh study covered more ground than mechanized mowing equipment in the same amount of time.

Mowing may deliver immediate results. However, it can be time-consuming. This inefficiency presents an opportunity to vegetation managers who would like to effectively treat more ROW acres annually.

Best Practices to Improve Mowing Results

In addition to increasing use-site productivity, targeted applications of selective herbicides are the key to optimizing vegetation control throughout utility rights-of-way. Unlike nonselective mowing strategies, targeted applications of selective herbicides help vegetation managers control the entirety of incompatible trees and brush species. Using these chemical strategies after mowing each use site can help industry practitioners significantly reduce the risk of regrowth in targeted plants.

An added benefit of this approach is that it gives beneficial low-growing plant species an opportunity to thrive. In turn, these native plant communities impede the future development of woody plant species, resulting in fewer maintenance requirements as time goes on. This notion was recently supported by findings generated by the State Game Lands 33 (SGL 33) research project, which has studied the ecological impact of vegetation management strategies throughout energy rights-of-way for nearly 70 years.

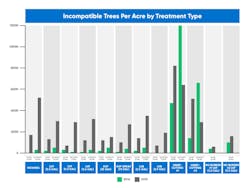

In a report from SGL 33 researchers with Penn State University, which details results from the project’s latest three-year research cycle, data shows that low-volume and high-volume foliar applications generally led to lower incompatible stem densities in the wire zone and border zone than plots managed with mowing or hand-cutting strategies (Figure 1).

Herbicide applications already require less manpower than mechanical mowing strategies, but their ability to reduce incompatible stem counts as part of an IVM-based approach also can reduce labor requirements and long-term maintenance costs. In fact, The Cost-Efficiency of IVM report from John W. Goodfellow directly compares IVM with non-IVM programs. In addition to indicating that IVM programs are 16% less expensive than mechanical mowing practices, Goodfellow’s findings show that vegetation managers can expect to increase mechanical mowing costs by 31% in the 10 years following a stoppage in herbicide use.

How Can Vegetation Managers Learn More?

When it comes to herbicide treatments, results will vary with the products and application strategies each program chooses to use. That’s why Corteva Agriscience provides product guidance and technical support to ensure utility vegetation managers are using the right solutions to control targeted vegetation throughout the land they manage.

To connect with your local vegetation management specialist, click here. In the meantime, learn more about the benefits IVM practices provide to utility vegetation managers by accessing this free utility vegetation management e-book from Corteva.

™ ® Trademarks of Corteva Agriscience and its affiliated companies.

Sponsored By: