Statnett's Removal of Fluid-Filled Submarine Cables

The national transmission system operator in Norway, Statnett SF, is a state enterprise wholly owned by the government. The utility owns, operates and constructs the main transmission system, which comprises some 11,000 km (6835 miles) of extra-high-voltage (EHV) and high-voltage (HV) overhead lines and underground cables as well as 150 substations. Together with partners, Statnett also owns and operates EHV submarine cable interconnectors to Denmark and the Netherlands and is installing new EHV submarine cable interconnectors to Germany and Great Britain.

In 2014, Statnett commissioned a new 13-km (8-mile) 420-kV submarine cable interconnection across the Oslo Fjord to replace a time-expired 12-km (7.5-mile) 420-kV interconnection comprising six 420-kV single-core fluid-filled (SCFF) cables in service since 1981. This interconnection is part of an important circuit in the Norwegian grid, with the demand for more transmission capacity was one of the reasons for installing the new cables. The new interconnection consists of nine single-core submarine cables.

Norwegian regulations outline the duties imposed on the concessionaire of electrical installations, specifying that, when removing assets from service, the concessionaire is responsible for removing the assets and restoring the terrain to its natural state as much as possible. The building and operating license granted in 2010 for the new 420-kV cable interconnectors included permission to operate the existing 420-kV cable interconnectors for five years beyond commissioning of the new interconnectors in 2014.

Removal Restrictions

The Oslo Fjord is a popular recreational area with many boats and yachts. It is also the main sea route into the Oslo region. Because the cable route crosses the main shipping lane, the removal operation had to be planned with the Vessel Traffic Centre of the Norwegian Coastal Administration.

In addition, two nature reserves had been established since the old cables were installed. Because of regulations, the removal project had to take into consideration the type of work and machinery that would be needed as well as the time of year in which the work would be done.

Environmental authorities regulate protected landscape areas and set the requirements on potential environmental hazards of a removal operation. The local fishing industry also has strong interests of access to the fishing areas in the fjord and in the removal of obstacles from the seafloor.

Removal Planning

The old 420-kV cable system installed in 1981 consisted of a two-part connection across the Oslo Fjord. Routed north of the new cable system, the old one was divided into two sections. The first section was routed from the western landfall at Teigen to Bastøy Island and the second section from the island to the eastern landfall at Evje. On the island, which later became a protected landscape area, there was a joint chamber where both sections of the cable system were joined by stop joints.

This two-section cable connection consisted of six SCFF submarine cables on both sides of the joints. One section was 4 km (2.5 miles) and the second section 8 km (5 miles), with the route crossing the fjord’s main shipping lane and having a maximum depth of 320 m (1050 ft). On both sides of the fjord, concrete shelters were built for the submarine cable terminations to connect to the 420-kV overhead transmission lines.

Because of limited documentation on all aspects of the old cable system and buildings as well as the closely connected operational steps needed, Statnett decided the removal project would be developed and engineered mostly in-house. The circumstances of having other submarine cable projects in the area, both in the years before and after, was a big advantage for this removal project because the same project team could lead it. Engineering considered the following main activities and operational sequence:

- Pre-removal survey

- Oil draining from cable ends

- Mobilization for marine operations

- Removal of concrete culvert covers

- Removal of cable joint protection mattresses and joints

- Cutting and sealing of cables outside the four landfalls

- Cable retrieval

- Cable disposal

- Removal of the oil-pressure system and termination buildings, in parallel with the maritime scope

- Recycling of disposed system parts and cables.

To complete a proper engineering assessment, a pre-removal survey was performed at the beginning of the project. The survey clarified there were no debris or features on the route that would impede the cable removal and the findings reconfirmed previous surveys of other subsea installations. With the survey and a detailed desktop study of all documentation on the cable system, it was possible to prepare a suitable operational sequence and create procedures for each operation.

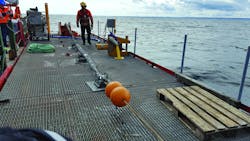

Statnett contracted with suppliers for the marine work. The utility had an appropriate marine contingency for the scope of work for both inshore and subsea work to retrieve the old cables across the fjord. Several elements of the project required vessels to perform work near the shoreline. The selected contractor had a cable-laying vessel, a barge, with a work-class remotely operated vehicle for monitoring, survey and small item cutting. The vessel also had the necessary equipment for the lifting jobs and to operate as a diver platform for the manually executed subsea work.

Existing Cables

The six SCFF cables installed west of Bastøy Island were single-core 1300-sq mm (8.4-sq inch) oil-filled copper cables with a lead sheath, armoured with a single layer of copper wires. The cable diameter was 128 mm (5 inches) and its weight in the air was 50 kg/m (34 lb/ft). The maximum water depth in this section of the cable route was 50 m (164 ft).

The six cables installed east of Bastøy Island were single-core 800-sq mm (5.2-sq inch) oil-filled copper cables with a lead sheath, armoured with two layers of flat steel wire. The cable diameter was 123 mm (4.8 inches) and its weight in the air was 43 kg/m (29 lb/ft). The maximum water depth in this section of the cable route was some 320 m (1050 ft).

The oil-filled cables had oil-pressure systems at all ends, both at the cable termination at the landfall shelters and at the cable joint chamber on Bastøy Island. To reduce the amount of oil in the cables—thus reducing the risk of an oil spill in the sea when performing the marine operations—each cable was drained. The oil-pressure system was disconnected from the cable ends, and the oil from the cables was drained by releasing the internal pressure within the cables. Putting air pressure on one end of the cable—to force the oil out of the other end—not only increased the amount of oil drained from the cables but it also emptied the oil duct in the conductor to a level where the subsea repair joints was drained.

Cable Landfalls

At each of the four landfalls, the old cables entered shore in concrete culverts with covers. The environmental authorities agreed to the final scope whereby the culverts and underground jointing chamber at Bastøy island would not be dug up, to protect the special landscape area. At the western landfall, the termination shelter site was reused for the new cable connection, but at the eastern landfall, the old termination shelter was removed completely and transformed back to a publicly accessible coastline.

Removing the subsea culvert covers was one of the first steps of the marine operations. Removing the covers revealed the cables and made it possible to pull them out from the shelter ashore. The covers were removed by a lifting operation with diver support. The cables in the culverts at Bastøy Island landfalls were cut and sealed to leave the protected landscape area with minimal interference.

Seabed Repair Joints

To retrieve the full length of the cables safely, by spooling the cables on the turntable aboard the cable-laying vessel, the subsea repair joints had to be removed from the cables beforehand. Considerable work was required to remove a total of five repair joints. The joints were removed by a combined diver and lifting operation. The joint protection mattresses were lifted onto the vessel. A diver then assisted with cutting the cable off from one side of the joint, and the joint with the cable attached was lifted onto the vessel. The joint was removed from the cable and the cable end was sealed before the cable was laid again on the seabed, before the second cable end was lifted on board to be sealed.

To keep oil leakage to an absolute minimum, oil was drained from the cables as well as the oil duct in the conductor and the order of the work considered the seabed inclination to cut the upper side of the joint first. The diver also temporarily sealed the cable ends for a short time before they were lifted on board.

Cable Retrieval

All this preparation made it possible to retrieve the full length of the cables safely. Then, a new challenge emerged. The outer protection jute yarn and bitumen on the old cables turned out to be decayed from being in the mud and seawater for so many years. The jute yarn was stuck on the cable rollers and wheels in the cable tensioner, majorly impacting the progress of the retrieval operation. The solution was engineered and built into the cable-laying vessel, whereby a high-pressure water jet and cone peeler ripped off the jute yarn simultaneously while retrieving the cable and loading it onto the vessel. The total operation was engineered and performed with the environment in mind. After the jute yarn was ripped off and collected on the vessel, it was delivered to the recycling contractor ashore.

In parallel with the retrieval of the cables, a receiving facility was established onshore to receive the full-length cables. The receiving facility was designed to operate at the same speed and working hours as the vessel, since the marine spread sets the operational timing and cost for this type of project. The receiving facility was required to be in the Oslo Fjord area because retrieval of all the cables would take several loads to bring ashore. A specialized recycling contractor established the receiving facility and performed processing, recycling and disposal of all parts of the cables.

The most important contributors of this project were Statnett Engineering Manager Geir Jensen and his team; the main marine contractor, Seløy Undervannsservice AS; the electro contractor, Infratek AS; and the recycling contractor, KMT Gjenvinning AS.

Working together with well-qualified contractors, Statnett executed the removal project with proper planning and well-prepared procedures. In the end, onshore shelters, oil-pressure systems, terminations, and 70 km (93.5 miles) of submarine oil-filled copper-cored cables were removed and disposed or recycled without any health, safety and environment incidents. The project’s total cost was around 85 million NOK and the income from the recycled cables around 55 million NOK as a result of a significant rise in metal prices, a total that was well within the original budget.

For more information:

Infratek | www.infratek.no

KMT Gjenvinning | https://kmtgjenvinning.no

Seløy Undervannsservice | https://seloy.no

Statnett | www.statnett.no

About the Author

Einar Tommelstad

Einar Tommelstad is a project engineer at Statnett SF. He holds a master’s degree in energy and environmental engineering from the Norwegian University of Science and Technology. Tommelstad has worked for six years at Statnett on many different high-voltage cable projects.

Carl Erik Hillesund

Carl Erik Hillesund is head of the cable department in the technology and development division at Statnett SF. He holds a master’s degree in electric power engineering from the Norwegian University of Science and Technology. Hillesund worked as a consultant for more than 15 years before joining Statnett eight years ago.