As early as 2008, generation auctions were held for hydroelectric expansions of the Santo Antonio and Jirau hydro power plants, built on the Madeira River in the state of Rondonia in northwestern Brazil. The preliminary installed capacity was 6940 MW. To transmit the output of these power plants, an auction was held to procure the public electric power transmission system, which included the construction, operation and maintenance of facilities within the Brazilian interconnected power system (BIPS).

The two Madeira River hydro power plants and associated transmission system encompassed a major Brazilian national project of strategic interest that not only increased electricity supply but also ensured supply continuity and security. The project required close coordination in planning. However, problems were experienced at the outset that resulted in changes to the construction timetable and the need to implement commissioning the project in four stages to comply with the availability of, and to benefit from, the commercial operation of the new generation and transmission system assets.

Madeira River Project Features

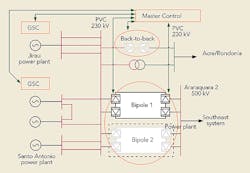

Porto Velho Collector (PVC) is a 500-kV substation located in north Brazil directly connected to two large hydro power plants constructed on the Madeira River. The Santo Antonio hydro power plant (SAPP) has an installed generating capacity of 3190 MW — from 44 72.5-MW units — and the Jirau hydro power plant (JPP) has a total installed capacity of 3750 MW, from 50 75-MW generators.

The PVC substation is designed to accept the incoming alternating-current (AC) power from four overhead lines from SAPP, which is 15 km (9.32 miles) away, and three overhead lines from JPP, which is 95 km (59 miles) away. This supplies the capacitor commutated converter back-to-back (BtB) and two ±600-kV high-voltage direct-current (HVDC) bipole lines. Each line is 2375 km (1476 miles) long, rated at 3150 MW and part of BIPS.

The bipole lines are connected to the Araraquara 2 (ARA2) substation, which supplies the major load centers located in the southeast region. Also connected to the 500-kV bus bars in the PVC substation is a 500/230-kV, 465-MVA transformer in parallel with the BtB converters that supply the Acre-Rondonia (ACRO) system in a provisional scheme.

Stage 1. Santo Antonio Generation

A mismatch between the generation and transmission construction schedules resulted in the first generators in SAPP and the first 500-kV intertie to the PVC substation being commissioned in March 2012. This resulted in a delay in the erection of the BtB converter blocks and bipole 1 in the PVC substation, and there was no available means to intertie SAPP to BIPS.

The technical solution chosen to tie SAPP synchronously to the existing 230-kV ACRO system was the installation of a 500/230-kV, 465-MVA transformer and BtB converter in parallel in the PVC substation. The transformer was connected to PVC’s 500-kV bay, originally designed for the fourth 500-kV circuit to intertie the left-bank powerhouse of SAPP.

Switching overvoltage studies were performed to evaluate the energization of the parallel transformer from both sides (the 230-kV and 500-kV terminals). The parallel transformer energization from the 500-kV bus bar exhibited unacceptable temporary overvoltages. However, the parallel transformer energization from the 230-kV side (on the ACRO system) was possible with low overvoltages and proper electrical damping. At that time, the ACRO system was operating with only one 230-kV circuit from the Vilhena substation in Rondonia to the Rio Branco substation in Acre, Brazil.

Stage 2. Back-to-Back Converters

The BtB converters have been in operation since 2012. With the parallel transformer and 230-kV ACRO transmission system connected to the SAPP generators, this provided a temporary, as opposed to the planned, solution.

At the time of the first BtB converter transformer energization on the 500-kV side, the transformer switching operation would not have been feasible if the parallel transformer had not been in operation, because of the low short-circuit power from SAPP and lack of electrical damping. System studies indicated the operation of SAPP together with the parallel transformer was feasible because of the reduced generation capacity at the time, resulting in the following added benefits:

• The parallel transformer helped to absorb part of the reactive power from the BtB harmonic filter banks (142 MVAR) in steady-state mode.

• In the event of a BtB converter blocking, and filter trip operation failing, the parallel transformer enabled a reduction in the minimum number of generators in SAPP to avoid the self-excitation phenomena.

• In case of a system fault resulting in blocking of the BtB converter, the parallel transformer takes over the resulting power flow of the blocked BtB converter and, consequently, reduces the impact on the 230-kV ACRO system.

• In the event of operational unavailability of the BtB blocks, the energy generated by SAPP can be transferred to BIPS through the parallel transformer.

The second 230-kV ACRO system transmission line erected between the intermediate substations (Vilhena, Porto Velho, Abunã and Rio Branco) was commissioned in 2013. The commercial operation of these lines then allowed a larger power interchange between the ACRO system and the rest of BIPS.

At this stage, the number of generators in service in SAPP did not allow simultaneous operation of both BtB blocks with two 142-MVAR filters together with the parallel transformer. This was because only one BtB block was in operation while the other was in standby mode, ready for operation. Thus, in the event of a BtB converter fault, the standby converter was operational without the need for insertion of the other 142-MVAR filter bank.

Stage 3. HVDC Bipole 1

HVDC bipole 1 began commercial operation in late 2013. Because of the reduced number of generators available for operation — namely, 12 units in SAPP and one unit in JPP — and the constraints of the ACRO system as a result of the delayed completion of the third 230-kV ACRO system transmission line, further temporary project design changes were needed. The safest way to maximize the power transfer from the Madeira River power plants to the southeast area of the country was to use bipole 1 in monopolar mode with metallic return.

System studies confirmed, with the reduced number of generators in SAPP and JPP (13 in total), only one 263-MVAR filter sub-bank could be energized safely in the PVC substation because of the self-excitation phenomena. This limited the power-transfer capability of bipole 1 in monopolar operation to 236 MW because of harmonic performance.

The rating associated with the AC filter banks of bipole 1 confirmed it was possible to operate bipole 1 in monopolar operation with power flows up to 700 MW and only a 263-MVAR filter sub-bank. Nevertheless, this solution also required the parallel transformer, together with the energization of a 59-MVAR BtB filter and its 63-MVAR reactor in the 230-kV PVC substation, to meet the harmonic performance criteria on the 230-kV system.

The original value for the master control function to switch on the second 263-MVAR filter was 236 MW to meet harmonic performance. At this stage, the value for the connection of the second filter was modified provisionally in the master control to 700 MW, to enable the operation of bipole 1 in monopolar mode with power up to 700 MW using only one filter bank.

System studies concluded there was a need to install a special protective scheme for immediate tripping of the parallel transformer in the event of blocking bipole 1. Also, bipole 1 could transmit up to 700 MW, with the excess of 700 MW generated by the Madeira River power plants being exported to the ACRO system. However, this power export is limited by events such as commutation failures and bipole 1 blocking.

HVDC Master Control

The functions to be performed by the master control related to the SAPP and JPP hydro power plants, in the absence of the generator station coordinators, were designed to be met by the bipole control, special protective scheme and operational measures. The reduction in the bipole 1 power-transfer capacity to conform the available hydro power generation cannot be undertaken by the master control in the absence of generator station coordinators. Thus, in stage 3, this action was performed by the bipole 1 frequency control.

In accordance with the Madeira River HVDC project design, the control functions that demand coordination among the HVDC bipoles, BtB blocks, SAPP and JPP, in normal conditions and in an emergency, are accomplished by the master control. In particular, the main functions implemented by the master control is to control the reactive power for a given transmitted power. Also, the minimum number of synchronized generators at the plants must be controlled to avoid self-excitation phenomena and the minimum set of filters must be controlled for safe operation of the converter station considering the circuit rating and harmonic performance.

There is a need for fast information exchange between the master control, which is installed in the PVC substation, and the generator station coordinators installed in both power plants. One of the main tasks of generator station coordinators is to inform the master control continuously of the total active power being generated and the total number of generators in operation in SAPP and JPP. Further, the master control must be informed if generators are tripped so the master control can reduce the HVDC converter’s power. This action is called runback. Finally, the generator station coordinator is responsible to disconnect generating units as requested by the master control.

Stage 4. Design Rating

Because of the progressive commissioning of generators in SAPP and JPP, there was an increase in available power to be transmitted by the HVDC system. This increase made it possible to carry out the commissioning works still pending in the HVDC system. Currently, there are 32 72.5-MW generators in commission at SAPP, totaling 2240 MW and 20 75-MW generators in commission at JPP, totaling about 1400 MW.

Taking into consideration the available generation capacity, the total output for the transmission system could be increased to 3150 MW in bipole 1 and to 400 MW in the BtB supplying the 230-kV ACRO system. The latter power capability remains limited to a single converter block until construction of a third 230-kV transmission line between Porto Velho-Jauru is completed.

The operation at these high design levels highlights the importance of integrated operation between the master control and generator station coordinators to facilitate the adjustments necessary to optimize system performance. The disturbance analyses undertaken have been central to the evolution and development of this system.

The power now being transmitted by the Madeira HVDC system has been important because of the injection into the BIPS at the ARA2 substation, which is very close to the southeast load center facing one of the largest droughts in history.

The 500/230-kV parallel transformer installed on a temporary basis at the PVC substation is still energized and on standby to black-start SAPP generators when required.

Overcoming the Challenges

The Madeira River project proved to be complex and challenging, and demanded intermediate operational stages not foreseen by the initial planning authorities. This required changes to the BtB and bipole 1 control systems. Extreme care has been exercised to ensure the safe operation of these systems was not compromised. The main causes for the operational stages were linked to delays in the generation schedule of the Madeira River power plants.

In addition, the delays in generator station coordinator deployment resulted in the need for special protective scheme. The use of a parallel transformer in the PVC substation provided a means to energize the converter transformers for BtB blocks and bipole 1. This parallel transformer also is used for black-start purposes.

Antonio de Pádua Guarini received a BSEE degree from the Federal University of Itajubá, Itajubá, Brazil, in 1974 and a MSEE degree from the Federal University of Rio de Janeiro, Brazil, in 1981. He was with CEPEL from 1974 to 1996. In 1999, he joined Operador Nacional do Sistema Elétrico, the Brazilian system operator, where he deals with power system restoration, protection system studies and HVDC Itaipu, Madeira and Belo Monte projects for the Brazilian interconnected power system.

Antonio Ricardo de Mattos Tenório received a BSEE degree from Federal University of Pernambuco, Brazil, in 1982 and a MSEE degree from the University of Manchester, UK, in 1995. Tenório joined CHESF (Brazil) in 1982 and, in 2000, joined ABB Power Systems in Sweden, moving on to join Operador Nacional do Sistema Elétrico, the Brazilian system operator, in 2004. His areas of interest include HVDC links, FACTS controllers, electrical and electromagnetic transient studies, and power quality.

Paulo Eduardo Martins Quintão earned a bachelor’s degree in 1993 and a master’s degree in power systems in 1999, both from Federal University of Rio de Janeiro. He worked for CEPEL from 1993 to 2008 developing small-signal stability analysis software. In 2008, Quintão joined Operador Nacional do Sistema Elétrico, the Brazilian system operator, in Rio de Janeiro to focus on power system special studies, protection and control areas.