One Year Later: Inside America’s Largest Dynamic Line Rating Deployment with Great River Energy

Key Highlights

- DLR measures real-time line conditions, revealing capacity increases over traditional ambient adjusted ratings, especially during wind-driven cooling in winter and summer.

- Peak-load capacity gains are crucial; during hot summer evenings, DLR unlocked up to 63% more capacity when demand is highest, improving grid reliability and reducing congestion.

- Full realization of potential is limited by system constraints; understanding and managing these is key to maximizing ROI and operational efficiency.

- Successful DLR deployment requires regulatory support, cultural buy-in, operational integration, and trust in data, not just technical upgrades.

- Sharing proven practices and lessons accelerates industry-wide adoption, helping utilities address surging demand, aging infrastructure, and extreme weather challenges.

The potential of dynamic line rating (DLR) has been circulating in utility circles since the early 1990s. For more than three decades, studies and pilots have proven that DLR can unlock transmission capacity by using real-time weather and line conditions.

So why, in an era of record demand, aging infrastructure, and extreme weather, isn’t it standard practice?

In the U.S., adoption has been slowed by a mix of regulatory friction, limited incentives, and internal inertia. The DLR industry itself hasn’t always helped: Headlines touting "40% average capacity gains" may be technically true, but they oversimplify a complex solution. When the promise of extraordinary capacity gains fails to materialize in a deployment, it risks undermining confidence across the entire sector.

And that’s the crux: In a risk-averse industry like ours, a single misstep doesn’t stay local—it echoes industry-wide—and most utilities want to wait for proven, peer-validated success before moving forward.

That’s what makes Great River Energy’s experience so critical. One year into the country’s largest DLR deployment, we’ve proven real impact. Yes, capacity gains, but also ratepayer savings, resilience improvements, and operational efficiencies. It’s not simple, and it’s not one number: It’s a system-wide story shaped by wind patterns, load profiles, grid constraints, and capital realities.

No single utility can tackle today’s grid challenges alone. Recognizing this, Great River Energy and Heimdall Power developed a collaborative approach grounded in real-world experience.

Their report, Grid Optimization Gets Real: One Year Inside America’s Largest DLR Deployment, draws on actual data, deployments, and results to offer practical guidance for evaluating grid-enhancing technologies (GETs), designing effective pilots, and applying a structured checklist to improve DLR performance.

At the heart of the findings are three key truths about dynamic line rating (DLR), based on field-tested performance rather than vendor claims. These insights provide a roadmap for utilities seeking to build a more resilient, flexible, and cost-effective grid.

Scaling DLR begins with evidence-based practices—focusing on what is proven to work in the field.

Great River Energy’s Results

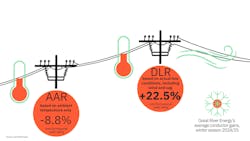

1.The wind changes everything: The difference between ambient adjusted ratings (AAR) and DLR isn’t just technical—it’s transformational. Whereas AAR adjusts line rates based solely on ambient air temperature, the DLR sensors measure and account for all the heating and cooling factors that determine the true line rating. That difference was on full display during the winter of 2024, when real-time conditions told a dramatically different story than the AAR models.

Ambient adjusted ratings suggested an 8.8% decrease in conductor capacity. Why? Because ambient temps were slightly warmer than the conservative seasonal assumptions.

But DLR revealed what AAR couldn’t: Minnesota’s signature winter winds were hard at work, significantly cooling the conductors. By directly measuring sag and current of specific sections of the total line to determine the true cooling of the line, DLR showed a 22.5% average increase in capacity—flipping the script from constrained to optimized.

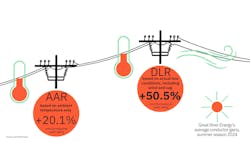

This pattern held into the summer. As wind continued to play an outsized role in real-time line performance, DLR consistently revealed more than double the capacity of AAR on several spans.

When you can see the grid as it actually is—not what models predict—it opens up new paths to reliability, affordability, and smarter capital investment.

2. Average capacity gains are good, but peak-load gains are a game-changer: The original goal of Great River Energy’s DLR pilot was simple: Increase transmission capacity and relieve congestion. Like many utilities, we already knew where congestion occurred, and just as importantly, when it tended to strike, based on seasonal patterns.

And that timing is everything.

Across the 2024 summer season, DLR revealed an impressive average capacity increase of nearly 50% on the pilot line. But not all capacity is created equal. Extra headroom at 5 a.m., when temperatures drop and electricity demand bottoms out, isn’t where the real pressure lies.

Demand surges between 4 p.m. and 10 p.m. on hot summer evenings, as families return home, air conditioners hum to life, and appliances compete for power. That’s when Great River Energy’s grid is pushed hardest—and where DLR delivered its greatest impact.

During these hot, peak-demand hours, DLR helped Great River Energy unlock 63% more conductor capacity compared to seasonal ratings. That’s not just added value—it’s actionable headroom when and where we need it most.

3. Conductor capacity gains don’t always equal realized value: In the summer of 2024, Great River Energy’s DLR deployment delivered impressive insights: The pilot line conductor had +48.92% more capacity than its static seasonal rating suggested. That’s a jump from 142 MVA to a potential 211 MVA, a 69 MVA increase in theoretical transmission headroom.

But proving potential is one thing. Fully using it is another.

Like many U.S. utilities, Great River Energy couldn’t capture the full potential of those gains, and here’s why: DLR reflects the real-time, weather-based capacity of the conductor itself, which is only one element, albeit the most difficult to upgrade, of the whole circuit. The transmission flow is ultimately limited by the lowest-rated component in the system. In this case, interconnected utility equipment capped transmission at 173 MVA, meaning the actual realized gain was 31 MVA, not 69.

To further complicate the data, about 2% to 3% of the time DLR showed slightly lower ratings than the static seasonal baseline, typically due to low wind conditions or higher-than-expected temperatures. Without context, that might seem like a step backward.

But it’s not a failure—it’s visibility, safety, and reliability.

DLR gives utilities a clear, real-time understanding of system behavior that static models or AAR can’t match. Even when capacity can’t be fully unlocked, the awareness of system constraints—and the ability to monitor and manage them—is a leap forward in grid intelligence, operational precision, and long-term planning.

Without context, Great River Energy’s winter capacity gains or its realized transmission outputs across both seasons, could be easily misinterpreted. Afterall, an additional 31 MVA in transmission output seems paltry when compared to potential gains of 69 MVA, right?

Not for Great River Energy. The additional 31 MVA and the savings each megawatt produce on one line contribute to the total forecasted savings of $3.175 million in the form of avoided congestion charges impacting just Great River Energy over the five-year scope of its current DLR deployment.

Which is why right-sizing expectations and getting honest about ROI is so critical to a successful DLR deployment.

Know More, Power More

Dynamic line rating isn’t new, but its time has finally come. Great River Energy’s deployment has shown that DLR delivers more than just impressive capacity gains; it enables smarter, safer, and more resilient grid operations grounded in real-time visibility. Along the way, we’ve learned that DLR success can’t be distilled into a single performance metric. True value emerges when capacity, timing, weather, load, and system constraints are considered together—and when data is operationalized, not just observed.

Our journey wasn’t turnkey. It required regulatory navigation, cultural buy-in, operational integration, and above all, trust in data. But by building a program that prioritized visibility, accountability, and ratepayer value, we’ve demonstrated that DLR can be a high-return investment, not just a technical upgrade.

We chose to distill the hard-won lessons from America’s largest DLR deployment into actionable guidance for utilities ready to move from theory to impact. The challenges we face as an industry—surging demand, grid congestion, and extreme weather—can’t be solved in silos. But by sharing what works, we can accelerate meaningful, scalable change.

The promise of DLR is real. Now is the time to realize its full potential.

About the Author

Michael Craig

Michael Craig ([email protected]), supervising manager of energy and distribution management systems at Great River Energy, is a professional engineer in the state of Minnesota with an electrical engineering degree and MBA degree from the University of Minnesota-Twin Cities. Craig has worked at Great River Energy for 13 years and helps to ensure reliable operation of the supervisory control and data acquisition system as well as working with new technologies pertaining to system operations and the electric utility industry.

Tom Cleaver

Tom Cleaver serves as vice president of Heimdall Power’s North American operations, bringing more than two decades of experience in utility grid innovation. He spent 18 years at Cooper Industries (now Eaton), where he led global initiatives across utility substation and grid technologies. After Eaton, Tom helped pioneer the commercial launch of key GETs, including composite high-temperature low-sag (HTLS) conductors and CAT-1, the first commercially successful DLR solution. He holds a bachelor’s degree in electrical and electronics engineering from the University of Michigan and an MBA from Seattle University.