Electric Power Substations are the most challenging industrial environments for electronic devices to operate in due to the presence of high voltage combined with the remote and exposed locations. The environmental conditions are extreme enough that specific standards have been developed by IEEE and IEC committees to ensure that electronic equipment that is compliant will provide reliable operation in substation environments. The standards known as IEEE 1613 and IEC 61850-3 provide the specifications for electronic equipment to operate in the diverse and challenging conditions of electric utility substations. Electronic equipment that meets these standards will not only operate more reliably but will also have a longer life expectancy in a substation.

Figure 1. Thermal and Visual monitoring in high EMF environment

Environmental Conditions in a Substation

The following conditions are considered extreme in electric power substations and the electronic design must take these into consideration in order to comply with the IEEE and IEC standards.

Electromagnetic Radiation

A high voltage transmission substation can operate at 500kV or higher. At this voltage level, the electric current flowing through the power lines produces an electromagnetic field that can extend to over 300 meters. The electromagnetic field (EMF) causes interference and misoperation in electronic equipment if the proper design is not employed. The disturbances generated by high voltage lines, switch gear, breakers and other apparatus in the substation is known as Electromagnetic Interference (EMI) or Radio Frequency Interference (RFI). Electronic equipment that operates in the vicinity of high voltage apparatus must be designed with immunity to this type of interference to avoid misoperation and loss or corruption of data.

Electrostatic Discharge

Because there are large fields of electromagnetic radiation in substations there is a higher probability for electrostatic discharge, (ESD), charges to build up and cause damage. The ESD charges are released when the there is contact or near contact to a grounded object at lower voltage potential. The contact occurs from the charged body of a worker or through a tool that is being carried. If the grounded object is a piece of electronic equipment the electrostatic discharge will cause high current flow through the circuits and cause damage or destruction to components if the circuits are not properly protected. To provide proper protection from high levels of ESD the chassis and all network and communication ports on electronic equipment must provide a path to ground that avoids sensitive circuits.

Instability of Power Supply

Substations are the where the voltage supply is transformed and switched to and from different voltage levels and circuits. The switching causes voltage ripples, surges, interrupts or even outages on the primary power supply that is used for electronic equipment in the substation. Load switching from faults in the electrical system can also cause ground potential rise.

Electronic equipment in the substation must be designed to withstand interruptions and operate seamlessly under many variations of power supply including switching from primary AC power to backup AC or DC power.

Lightning

Due to the nature of substations being built with tall metal structures in remote areas, they are naturally more exposed to lightning strikes. Even though many substations are designed with sophisticated lightning protection and grounding systems there are still substations with no lightning protection. Lightning protection generally covers a 30º arc under the lightning protection cable and often does not protect the fence line where the camera poles can be located. Even with proper lightning protection in the substation, problems can still arise from voltage surges and ground potential rise for electronic equipment that is not designed to withstand it. Electronic equipment must not only be designed to withstand voltage surges but must also be installed correctly with particular attention to proper grounding.

Extremes in Weather and Climate

While some modern substations have control rooms that are climate controlled, the vast majority of remote substations are unmanned and without climate control. Even if the control room is climate controlled the electronic equipment is expected to operate reliably in outdoor environments with or without equipment cabinets. The equipment must be able to withstand extremes in high and low temperature and humidity. Equipment that operates outdoors must have the correct ratings to be protected from sun, dust, dirt, wind, rain, snow and ice. The operating temperature ratings must not rely on the use of fans as moving parts are usually the first point of failure.

Designing for the Effects of the Substation Environment

Eliminating the Most Common Failures

The components in electronic devices that are most likely to fail are 1) power supplies and 2) motors. High reliability equipment designed for substation use should be designed with redundant power supplies that can be powered from independent sources. This provides redundancy on the unit’s own power supply as well as from the power source. If the primary AC source goes down the unit can draw DC power from the substation battery to keep running. Secondly, the electronic equipment should be designed without moving parts such as spinning drives and cooling fans/filters. Substations located in remote locations are difficult to access and perform maintenance on and the mechanical components are among the first things to fail. The substation standard specifies equipment must operate at full specified temperature ratings without cooling fans so they are virtually maintenance free.

Figure 2. Utility grade equipment can be located in close proximity to high voltage lines,

Substation Standards

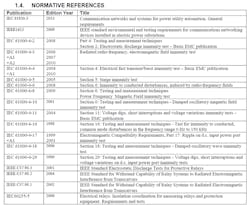

Substation Engineers recognized the fact that intelligent electronics devices, (IEDs), would be increasingly used in substations. They also knew that they had to be designed differently to work reliably in the challenging environmental conditions. The IEEE created a standard known as “IEEE 1613 Standard Environmental and Testing Requirements for Communications Networking Devices Installed in Electric Power Substations.” Along the same lines the International Electrotechnical Commission, (IEC), created a standard known as IEC 61850-3. This standard, “defines the general requirements, mainly regarding construction, design and environmental conditions for utility communication and automation IEDs and systems in power plant and substation environments.” The IEEE standards are more recognized in the U.S. while the IEC standards are more recognized globally. It is generally a requirement for IEDs being used in a substation to meet the requirements of either one or both of these standards. For a manufacturer that markets products globally, it is common for them to ensure their products meet both standards.

Conclusions

Commercial grade equipment may initially be more attractive due to its low cost but the return on investment may not be as expected if the equipment cannot perform or last long in the harsh conditions of a substation. The cost of maintenance, repair and replacement at remote substations is both costly and inconvenient and can surpass any savings that were had on less expensive electronic equipment. Utility grade equipment that is tested to IEEE 1613 and IEC 61850-3 uses higher quality components and more expensive design that is required to meet the standards. This provides the assurance that the equipment is designed for the conditions in a substation and will provide low maintenance, high performance and long life.

Sponsored by: