Power Infrastructure Seen as a Community Asset

Seattle City Light’s Denny substation is a stunning addition to the Emerald City’s South Lake Union neighborhood and sets a model for others to emulate for integrating infrastructure into the cityscape.

Utilities are increasingly building new substations in busy central districts to provide power to the additional electrical load density associated with development. This means size, noise and visual appeal are key factors in design. Big-city substation designs also need to provide system protection and reliability, just like their suburban and rural counterparts. Seattle City Light (SCL) was able to overcome these tough challenges in Seattle, Washington, U.S., because the utility and its design team were committed to a successful project.

State-of-the-art technology, skilled and diverse engineering, and a community-focused public involvement program enabled the utility to integrate its high-voltage Denny substation into an urban setting in a way that is entirely compatible with the densely populated South Lake Union neighborhood. Energizing the substation in May 2018 and completing exterior features later in 2018 will culminate in a singular effort to introduce the community-friendly facility.

Public Benefits

The Denny substation uniquely proclaims its location and provides spaces for people to not only view the workings of the substation but meet, play and eat as well as enjoy outdoor art. Denny applauds its function as a substation and invites the community to celebrate its place in Seattle.

The first Seattle substation to be built in 30 years, Denny includes 44,000 sq ft (4088 sq m) of open space as part of the package of public benefits required due to the street vacation and urban design merit that will activate these areas and provide features that benefit the public. These include an off-leash pet park and a 0.25-mile (0.4-km) walking loop that rises 16 ft (4.9 m) above street level to provide pedestrians unique views of the surrounding area. One side of the site provides space for food trucks during lunch and neighborhood events.

The substation cuts across a block and a half, but its size does not overpower passersby because of a design by Seattle architecture firm NBBJ that angles the substation’s screening walls inward using a double cantilever to lower their visual profile. The walls are finished with a combination of metal cladding and glass panels. Glazing is along the bottom of the south and west walls, and then it switches to the top on the north and east walls. The rest of the walls have enameled metal panels that make them hard to climb and resistant to graffiti. When illuminated from within, the translucent glass panels emit a soft glow at night.

Among many sustainable features built into Denny are solar panels that offset the load of the two public-use indoor shell spaces and a heat-recovery system that enables the station to contribute to its own building heating. Nearly one-half the site’s exterior public space is planted with trees, shrubs and ground cover. A large containment vault captures potential oil spills and serves to collect all storm water runoff from the substation interior area.

Behind its shimmering walls, the substation transforms high-voltage energy from SCL’s portfolio of mostly renewable resources into lower voltages used by the growing number of South Lake Union and Denny Triangle residences and businesses. New high-rise and mid-rise office towers, housing high-tech companies and residences, dot the neighborhood. The substation supports the new headquarters of Amazon.com, the University of Washington School of Medicine’s biotechnology and medical research hub, the Fred Hutchinson Cancer Research Center, the Seattle Cancer Care Alliance, the Bill & Melinda Gates Foundation, the global health organization PATH and the Washington State Convention Center.

Communication, Collaboration, Coordination

The project team included SCL’s internal team, which consisted of a program manager, project managers, substation engineers, and operations and maintenance personnel. In addition, the team worked with about 60 representatives not only from the utility but also numerous city departments. These included the Seattle Parks and Recreation, Seattle Department of Neighborhoods, Seattle Public Utilities, Finance and Administrative Services, Seattle Department of Transportation and others.

The consultant team included electrical, civil, structural and mechanical engineers as well as architects and landscape design, environmental and traffic engineers. Others involved were State Environmental Policy Act specialists, public outreach experts, an electromagnetic field (EMF) consultant, acoustical analysists, value management experts, cost estimators, surveyors, urban designers and geotechnical personnel. Much of the consultant team was local to Seattle and had direct experience with the local communities, Seattle Design Commission and Seattle City Council. The local connections proved important in navigating through the city’s political landscape.

The range of disciplines involved required careful planning to help them work together. This effort included weekly team meetings during the design phase. To help keep the team on the same path, everyone used the same software tools: Microsoft Office products, POWER360 project information management tool and Smartsheet work platform. During critical parts of construction, the program team held tailboard meetings daily and used Bluebeam and Prolog to manage project documentation during construction.

Besides NBBJ, the diverse program team included POWER Engineers Inc., which served as the program manager for the consultant team and oversaw electrical design, and KPFF Consulting Engineers, which provided structural and civil engineering services. ABB and Mitsubishi Corp. were the major electrical equipment suppliers and installers.

The substation design team, composed of SCL’s project team and POWER, worked diligently to make possible all the public amenities such as sloping screen-walls, indoor shell spaces, dog park and elevated walkway. These amenities placed additional challenges on the design team for space, access, safety and overall design for a substation with four operating voltages. The design team had to strike the balance between the requirement to provide functional, maintainable electrical power system infrastructure and the provision of amenities. This was not always easy.

Noise, EMF and Safety

When SCL proposed the Denny substation, residents in nearby buildings raised questions about noise and potential effects of EMF. SCL committed early to be a good neighbor and sought to address residents’ concerns through the consultant team. BRC Acoustics & Audiovisual Design created 3-D models to represent the noise emitters and structural components that would affect sound travel. The consultant team used acceptable sound levels from the 3-D model to specify equipment that would fall within these sound emitter limits. To reduce the potential for noise, designers placed low-noise transformers in the center of the station with the removable firewalls on three sides that helped with noise.

The design team also placed the 115-kV gas-insulated switchgear and 15-kV breakers in buildings, which not only reduced noise but addressed residents’ concerns about the equipment’s visual appearance, as well. Housing the equipment had the added advantages of faster and easier construction and protecting accessories from ultraviolet and weather damage, which happens in some open-air stations. Further addressing residents’ concerns, SCL agreed to no outside audible alarms, a change from usual practice.

Denny’s design features rendered EMF to very low levels. An analysis by the Seattle firm of Hatfield & Dawson Consulting Engineers, which specializes in electromagnetic engineering, confirmed EMF in the area would be no greater after construction of Denny than before. This is possible because there are no overhead lines and all the underground conductors are bundled together. When three conductors are in a triangle, the magnetic fields essentially cancel each other away from the conductors. The same is true for the 115-kV (and one future 230-kV) high-pressure, fluid-filled (HPFF) transmission lines, which are encased in a stainless-steel pipe.

As part of remediation before construction, SCL had to dig 40 ft (12.2 m) down from the surface in some areas to remove soil contaminated by diesel fuel from the Greyhound Bus maintenance facility that previously occupied the site. During that effort, workers drove 136 40-ft (12.2-m) shoring piles around the perimeter of the substation yard. POWER’s design took advantage of the I-beam piles to equip Denny with a super-safe grounding grid. This guards against unsafe ground potential rise, which occurs when large amounts of electric current enter the earth such as during an electrical fault. These, plus additional I-beams in the substation yard for shoring piles, for a total of 293, augmented the ground grid.

Prepared for the Future

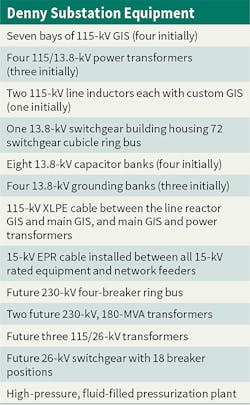

The substation was designed to accept additional equipment as part of its ultimate sizing. All the substation’s duct banks have been stubbed out, so new transmission lines and distribution feeders can easily be added. Additionally, shoring piles for future vaults have been installed to simplify the installation of future vaults in a live substation.

Denny substation is part of a project to convert the South Lake Union’s 26-kV radial distribution system to an underground 13.8-kV network distribution system, which will provide more reliable electrical service to denser loads. The distribution project involves the design and construction of 12 new network feeders (ultimately, 24) that exit the substation in seven duct banks through heavily trafficked roadways and about 3.5 miles (5.6 km) of city streets in north downtown.

One of the factors that influenced Denny’s location was the 115-kV HPFF line that already ran through the site. During construction, the line was above grade, cutting off access to the western quarter of the site. To energize Denny, workers spliced into the existing transmission line in two places to provide separate lines from Denny to the East Pine and Broad Street substations, enabling removal of the portion of the line that bisected the site. The HPFF transmission line has the potential for the East Pine line to uprate from 115 kV to 230 kV in the future to meet electrical demand.

Model Infrastructure Project

SCL successfully worked with the community and the City of Seattle to deliver a substation that meets the energy needs of the rapidly developing South Lake Union and Denny Triangle areas. However, Denny substation is more than just a functional substation. Denny fits with its surroundings and is an attraction that offers benefits to the community. The complexity of the project, the many disciplines employed and the various city departments engaged required continuous involvement throughout the life of the project. The design of Denny substation proved to be a huge win for everyone involved.

Infrastructure projects can be built in a big city and do not have to be eyesores. It starts with being sincere about making the project a benefit to the utility and the public. Challenges can be met with sound teamwork, good communication and solid relationships with local companies as well as by staying neutral as the local political process plays itself out.

SIDEBAR: Drones Over Denny

POWER Engineers Inc. used unmanned aerial systems (UAS), or drones, to give the project team a detailed look into Denny substation to provide a better understanding of the issues they had to face.

Using Inspire 1 Pro (Rotorcraft) for the job, POWER collected imagery and video to create an accurate 3-D model of the project at milestones during the life span of construction. With each 3-D model stored in an online interactive application, designers made distance-based inspection of the project possible from across the globe. Construction progress could be compared against the project schedule.

Using the drones also proved to be a lesson in preflight planning and knowing the airspace. Although the flight area was outside the Seattle-Tacoma International Airport zone, pilots had to coordinate with eight separate airport managers, including seaplane bases and helipads for surrounding hospitals and news stations.

One flight path conflict required pilot diligence: Seagulls sometimes took exception to drones in their airspace and went after the unmanned invaders.

Michael Clark ([email protected]) is the substation program manager for Seattle City Light and a project management professional with more than 30 years of experience managing and coordinating municipal infrastructure and urban development projects. His strength and expertise in supporting complex project implementation in high-density urban centers is a focused and comprehensive approach in aligning strategic business and operations planning, policy development, project management, conceptual and technical design, operational and workload planning. Clark was instrumental in coordinating activities with the Seattle Design Commission, Seattle City Council and Seattle City Light management.

Joe Orth ([email protected]) is a principal engineer in the substation engineering group of Seattle City Light with more than 30 years of experience designing and constructing major utility infrastructure projects in generation and T&D. His expertise includes innovative ways to solve problems major utility projects face and move these projects through the design process to completion. He is Seattle City Light’s technical lead for the Denny substation project, a registered professional engineer and holds a MSEE degree from the Georgia Institute of Technology.

Jay Keeling ([email protected]) is a professional electrical engineer with 30 years of experience and a veteran POWER Engineers Inc. project manager who specializes in management and design supervision for large utility substation and transmission facility projects. His background is strong in advanced, sophisticated substation engineering, including projects through 800kV, and large compensation installations, including some of the largest installations in the world. He has expertise in complex, nontraditional station designs, including urban design, static volt-ampere-reactive compensator, static compensator, high-voltage direct-current, series compensation and gas-insulated switchgear.

For more information:

- ABB | https://new.abb.com

- BRC Acoustics & Audiovisual Design | www.brcacoustics.com

- Hatfield & Dawson Consulting Engineers | www.hatdaw.com

- KPFF Consulting Engineers | www.kpff.com

- Mitsubishi | www.mitsubishicorp.com

- NBBJ | www.nbbj.com

- POWER | www.powereng.com

- SCL | www.seattle.gov/light/dennysub/

About the Author

Michael Clark

Substation Program Manager

Michael Clark is the substation program manager for Seattle City Light and a project management professional with more than 30 years of experience managing and coordinating municipal infrastructure and urban development projects. His strength and expertise in supporting complex project implementation in high-density urban centers is a focused and comprehensive approach in aligning strategic business and operations planning, policy development, project management, conceptual and technical design, operational and workload planning. Clark was instrumental in coordinating activities with the Seattle Design Commission, Seattle City Council and Seattle City Light management.

Joe Orth

Principal Engineer

Joe Orth is a principal engineer in the substation engineering group of Seattle City Light with more than 30 years of experience designing and constructing major utility infrastructure projects in generation and T&D. His expertise includes innovative ways to solve problems major utility projects face and move these projects through the design process to completion. He is Seattle City Light’s technical lead for the Denny substation project, a registered professional engineer and holds a MSEE degree from the Georgia Institute of Technology.

Jay Keeling

Jay Keeling is a professional electrical engineer with 30 years of experience and a veteran POWER Engineers Inc. project manager who specializes in management and design supervision for large utility substation and transmission facility projects. His background is strong in advanced, sophisticated substation engineering, including projects through 800kV, and large compensation installations, including some of the largest installations in the world. He has expertise in complex, nontraditional station designs, including urban design, static volt-ampere-reactive compensator, static compensator, high-voltage direct-current, series compensation and gas-insulated switchgear.