Grid Energy Router Project Proves a Success for Farmers

Power electronics has been touted as an effective way to introduce active power control downstream of the substation, closer to the point of consumption. In 2017, the Central Electric Power Cooperative (CEPCI) and the National Rural Electric Cooperative Association (NRECA) partnered to field-test a device, termed a grid energy router (GER), which uses power electronics to provide precise voltage control, improved power quality and add a communications function to transformers.

This research project grew out of the CEPCI’s desire to meet the needs of agricultural members and their cooperative electricity providers in South Carolina for demand-savings programs, improved power quality and system efficiency to improve the members’ profitability. With help from 20 South Carolina distribution cooperatives and its agricultural advisory team, the CEPCI focused on delivering a technology solution to meet this need. After a review of commercially available solutions, the CEPCI and the NRECA decided to deploy ERMCO-GridBridge Grid Energy Routers. This distributed control capability within a feeder aligns with the increasingly distributed architecture of the electric system, which is accommodating technologies such as solar, energy storage and electric vehicles.

This active technology was expected to function in two applications. First, it was intended to work in coordination with existing substation-based Volt-VAr Optimization (VVO) programs to maximize the effect of those programs and in this way, reduce cost to members. Second, it was intended to mitigate demand charges by using localized voltage and VAr optimization at qualified production agriculture sites. The installed devices were expected not only to control voltage on the secondary side, but also to simultaneously control the source side power factor. As an added benefit, the constant and nameplate-aligned voltage provided to motors was expected to extend the life span of the motors.

Four different cooperative members of the CEPCI participated and collectively deployed units on farms at six different locations. Within the South Carolina distribution co-op network, more than 3,000 meters serve agricultural members, including poultry, swine, tobacco and irrigation applications. Therefore, applying the state-of-the-art technology to benefit the co-ops and the consumer members simultaneously would provide its agricultural members with ways to lower operational costs through demand and energy savings. that can benefit both the co-op and the members. The poultry farming members were considered the most compelling to study since those customers use large quantities of power, operate with consistent loads across seasons, need to supply a good mix of resistive and inductive loads, and were available at various locations in the Carolinas.

“Conducting this collaborative project through the NRECA’s regional research program enables co-ops across the network to work together, gain experience and understand new technologies, business models and systems,” says Jim Spiers, NRECA senior vice president for business and technology strategies. “This approach meets the membership need for use-cases that are developed through real-world field testing and implementation, which can then serve as reference for broader deployment across the cooperative community and utility companies nationwide.”

Controlling Electricity Expenses Matters

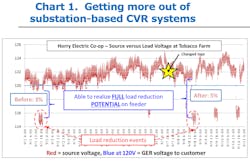

Within the first application, Horry Electric Cooperative, which services nearly 80,000 customers on the western side of the Intracoastal waterway in SC, served as the participating utility. As part of this program, Horry’s engineering team identified constraining locations within a feeder that were limiting the load control benefits of its substation based VVO program. Prior to installing the GER, the substation regulator taps were operating at a constrained 3% versus the original program’s 5%. This severely limited the performance of the VVO program. Horry Electric considered the GER technology and deployed it at a tobacco farm that otherwise faced challenges each time the feeder was put into load control mode.

From chart 1, captured after the GER was installed, the red line indicates voltage that would have otherwise been provided to the tobacco farm, including load control events. The blue line indicates the voltage that was ultimately provided to the member’s tobacco farm. This constant voltage not only benefited the members’ equipment, but it also isolated this sensitive location from load control events. The substation taps were returned to the original 5% and the blue line indicates a constant voltage of 120V per leg to the member. The GER enabled Horry Electric to receive the full benefit of its VVO program within this feeder.

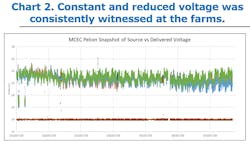

The second application included three cooperatives that serve nearly 200,000 customers throughout a wide geography in SC: Mid-Carolina Electric Cooperative, Black River Electric Cooperative and Blue Ridge Electric Cooperative. Poultry farms were targeted in these service territories for their load size and relatively consistent power consumption across all seasons. The GER technology task in this application was to deliver Distributed Load Control, but with a higher degree of control and improved power quality to members, all of which would be transparent to operations. While the GERs could potentially only be operated during periods of peak demand, in this program, each participating co-op chose to set the voltage at a constant and reduced level 24x7.

Results: Controlled Voltage

The research team designed an experiment for the two pilot projects that included capturing the energy consumption data via independent metering across numerous grow cycles at the test houses and control houses. The five locations provided an exceptional cross section of varied farm size and vintage, as well as electrical operating conditions. First and foremost, the team found that there was no adverse impact on farm operations after installation of the GER. Consistent and reduced voltage was repeatedly witnessed at the farms, as seen in chart 2.

The technology worked to reduce demand and consumption, plus the energy savings generated across sites consistently ranged from 8% to 10% depending on the size of loads and local grid voltage levels. For testing purposes, voltage regulation was set somewhat arbitrarily at 232V, but in practical application, could be further adjusted to achieve higher demand reduction and efficiency savings for customers. The ability to simultaneously improve power factor was also witnessed. It’s known that the correction of power factor leads to less overall heating of the feeder and transformers within, although the financial benefit was found difficult to calculate.

Through this program, the team demonstrated that active control capabilities of power electronics-based devices can be used downstream of the substation to help production agriculture customers. While only two types of farms were included in this research, the conclusions apply across the production agriculture industry. “Lowering peak demand is a key focus and decreases power costs for the co-op,” said Scott Hammond, members program manager at CEPCI. “It’s also a real win when we find ways for our distribution co-ops to help their members save energy while simultaneously benefitting their distribution infrastructure.”

The deployed GER devices offer the advantage of “set and forget,” which was beneficial to the farmers, who agreed to participate only if the technology didn’t distract from normal farming operations. This autonomous operation was also important considering the rural locations of the installations and inherent periods of communications outage.

The testing team noted there weren’t any failures over the two-year monitoring period and there was consistently good communication between the vendor and participating utilities.

“From our experience, the ERMCO-GridBridge product worked as advertised, which makes these sorts of programs a lot easier on all of us,” said Kevin Jordan, supervisory engineer with Horry Electric.

Summary

For agriculture customers operating on razor-thin margins, controlling electricity expenses matters. Over the past 70 years technology advancement has resulted in a near tripling of farming output and productivity. Working with its many electric cooperative members that provide electricity to farms large and small, the NRECA has fostered research focused on developing and testing new technologies and applications that can help farm businesses maintain competitiveness and increase productivity and profitability.

The combined research team verified through the GridBridge test program that technology providing distributed active control can benefit both agriculture customers and the utilities that serve them. Considering the bigger picture, having this sort of granular control allows the utility to react in a much more precise fashion while distributed technologies such as solar and energy storage are coming online. Most importantly though, there are multiple applications to justify the investment.

By understanding the constraining points within a substation based VVO program, individual locations can then be boosted up or bucked down. This flexibility can help utilities get more out of their existing VVO programs and further reduce demand charges.

With a UL-approved device, such as the technology tested in this program, the GER can be installed on either side of the meter to reduce demand and consumption. On the utility side of the meter, it allows the utility to introduce new rate structures related to efficiency and power quality while also modernizing electrical infrastructure to meet future needs related to distributed energy resources. On the customer side of the meter, the utility may simply choose to include the technology within a pre-existing energy efficiency financing program.

Very importantly, it provides financial benefits for the utility’s customers while also benefitting the utility network, as well as the integrator operating within the service area.

About the Author

Brian Sloboda

Brian Sloboda is the National Rural Electric Cooperative Association’s Cooperative Research Network Director, Consumer Solutions. Brian has over 20 years of experience in evaluating emerging technology and its impact on consumers.