Modernizing the Grid: PG&E's Approach to Aging RTUs and Next-Gen Substation Systems

Key Highlights

- PG&E is modernizing its substation automation to improve reliability, cybersecurity, and integration with renewable energy sources.

- The upgrade focuses on replacing outdated RTUs with modular, scalable systems capable of handling increased data and operational demands.

- The 'Four Ps' strategy guides the project, emphasizing system performance, usability, cost-effectiveness, and future-proofing for emerging technologies.

- Enhanced automation will enable faster diagnostics, fault isolation, and better grid management, supporting California's clean energy goals.

- This transformation aims to serve diverse communities, improve resilience against natural disasters, and set a blueprint for utilities nationwide.

Related Event: Don’t miss the webinar, Undergrounding at Scale – PG&E’s Innovations and Lessons Learned. This session explores how PG&E is advancing grid modernization efforts beyond substations by strategically undergrounding power lines to reduce wildfire risk and strengthen reliability: September 22, 2025; 1:00 PM CDT. Register here.

In the heart of California, Pacific Gas and Electric Company (PG&E) is facing a major challenge — and an exciting opportunity. With thousands of aging Remote Terminal Units (RTUs) installed since the 1990s, PG&E is now working to modernize its substation automation systems to meet the demands of a smarter, more connected energy grid.

But this isn’t just about replacing old equipment. It’s about rethinking how the entire system works — from hardware and software to cybersecurity and future expansion. Here’s how PG&E is tackling this transformation and what it means for the future of energy.

What Are Substation Automation Systems and Why Do They Matter?

Substation automation systems are the brains behind the power grid. They monitor and control the flow of electricity, helping utilities like PG&E deliver reliable energy to millions of homes and businesses.

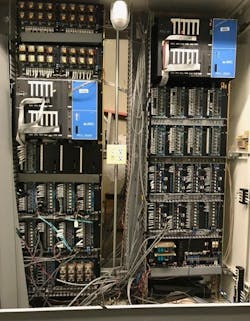

PG&E uses two main types of automation systems: RTU-based systems and Gateway/HMI-based systems. RTU-based systems rely on RTUs to gather critical data from meters, relays and other substation equipment. RTUs serve as data hubs, collecting information on voltage, current, breaker status and more — then relaying that data back to grid operators.

Gateway/HMI-Based Systems are a more modern approach that uses fast Ethernet networks to manage high volumes of data. These systems are suitable for newer setups like Modular Protection and Automation & Control (MPAC) enclosures, where advanced diagnostics and automation are essential.

The Problem: Aging Equipment and New Demands

Many of PG&E’s RTUs were installed more than a decade ago, some even in the early 1990s. Today, these units face several challenges:

- Outdated Technology: Some RTUs are now obsolete, and parts are difficult to replace. In some cases, the manufacturers no longer exist.

- Limited Capacity: These legacy systems struggle to keep up with today’s growing data demands, especially as the grid becomes more decentralized and data intensive. Existing RTUs data processing and handling capability has limitations in hardware and software to handle large volumes of real-time/non-operational substation data.

- Integration Issues: New technologies such as battery energy storage systems, rooftop solar and microgrids often aren’t compatible with the older RTU models.

- Rising Failure Risk: As with any aging infrastructure, the risk of performance issues or outright failures increases over time.

For PG&E, upgrading these systems is critical to maintaining reliability, especially as more Californians adopt electric vehicles, solar panels and smart appliances that place new demands on the grid.

The “Four Ps” of PG&E’s Upgrade Strategy

To guide this complex modernization efforts, PG&E is using a structured approach — focusing on four key dimensions, known internally as the “Four Ps”:

P1. System Function Perspective – focuses on how well the entire automation system works as a whole, not just how the individual pieces perform. The goal is to build an integrated system that can reliably collect, analyze and respond to data in real time. That means ensuring the RTUs and gateways have fast, reliable processors capable of handling modern data volumes and run on secure, real-time operating systems that can respond instantly to grid changes.

In addition, they are designed with modular hardware so they can be easily expanded or updated and offer strong protections against cybersecurity threats. They must also sync accurately with GPS and time servers to ensure data precision across the grid. By modernizing the functional core of its substation systems, PG&E is laying the foundation for faster diagnostics, better fault isolation and more responsive grid operations.

P2. System Application Perspective – focuses on usability, looking at how easy the system is to use and maintain. PG&E wants tools that are intuitive, support multiple communication protocols and help engineers troubleshoot problems quickly. These platforms should offer intuitive graphical user interfaces (GUIs) that simplify troubleshooting and support for multiple communication protocols to ensure compatibility with various devices.

They must also have configuration tools that streamline updates and make it easier to pinpoint problems. Advanced diagnostics and data analysis features can reduce on-site testing and speed up repairs. By reducing complexity in the field, PG&E can save time, lower costs and reduce the risk of outages due to human error.

P3. Company Financial/Investment Perspective – refers to the significant capital investment of upgrading hundreds of RTUs.

PG&E is being strategic in how it allocates resources — comparing the cost of retrofitting existing systems versus fully replacing them.

Key financial considerations include initial costs like hardware, software, licensing and labor for installation. Maintenance costs involve ongoing upkeep, including the ease of sourcing replacement parts. Expenses for training and transition relate to supporting field crews and engineers as they transition to new systems.

The total cost of ownership is evaluating not just upfront expenses, but long-term savings from better performance, reduced outages and lower operating costs. PG&E is also exploring whether existing hardware or configurations can be reused, reducing waste and increasing cost-effectiveness.

P4. Future System Expansion Perspective – looks to the grid of tomorrow. The energy landscape, specifically the grid, is evolving fast. PG&E’s upgraded systems must be built for the future, not just today.

That means making sure they can support distributed energy resources (DERs) like rooftop solar and battery storage and microgrids, especially in rural or wildfire-prone areas that benefit from local energy resiliency. They must also back renewable energy integration, as California pushes toward 100% clean electricity and artificial intelligence and machine learning tools that help predict grid behavior and optimize performance. Finally, they must encourage the development of digital substations using IEC 61850 and other global standards for next-gen automation and interoperability.

Future-proofing these systems now helps PG&E avoid expensive upgrades later, and ensures customers benefit from tomorrow’s innovations without delay or additional costs.

Why It Matters: The Bigger Picture

This upgrade project is part of PG&E’s broader commitment to grid modernization. By investing in smarter substation automation, PG&E is enhancing reliability as faster, more accurate data improves response times and outage management. It also supports clean energy because flexible automation systems are essential for managing the variability of renewable energy.

Another important part of the project is its ability to strengthen cybersecurity. Modern platforms provide better protection against growing digital threats. An additional benefit is driving equity. Improved automation helps PG&E better serve remote, underserved and high-risk communities.

Looking Ahead: Building a Smarter Grid

PG&E is not alone in facing the challenge of aging RTUs. Utilities across the United States — and around the world — are grappling with similar questions about how to modernize critical infrastructure while keeping costs manageable and reliability high.

With its “Four Ps” strategy, PG&E is offering a potential blueprint for how to do it right: balancing technical performance with usability, fiscal responsibility and forward-thinking design.

Serving more than 16 million people across a vast and varied service area spanning 70,000 square miles in Northern and Central California, PG&E needs systems that are as dynamic and resilient as the communities we serve.

About the Author

Michael Zhang

Michael Zhang ([email protected])is a principal automation engineer in Pacific Gas and Electric Company (PG&E). Mr. Zhang has more than 34 years of relevant professional experience in electric utility, oil and gas pipeline control and instruments measurement and telecommunication industries. He possesses strong management experience in operation and maintenance of power utility automation systems and instrumentation devices and solid knowledge and experience with SCADA/RTU and automation equipment, computer systems and instrumentation. He also has expertise in developing programs, and in solving a broad range of complex technical problems for clients. Mr. Zhang obtained a master’s degree in electrical and computer engineering in 1991 from Xi’an Jiaotong University in China

Frankie Au-Yeung

Frankie Au-Yeung ([email protected]) is a principal automation engineer/ MPAC program manager in the Substation Automation Engineering department at Pacific Gas and Electric Company (PG&E). He received his bachelor’s of science degree in electrical engineering from San Francisco State University in 2000 and his MBA in 2006. He has 25 years of expertise in power system protection and substation automation, including 15 years of managing the Modular Protection Automation and Control program (MPAC). He is responsible to lead and interact closely with cross-functional teams, MPAC contractor/building vendor and performance metric management, managing the MPAC program/projects, and responsible for the annual Automation T&D Capital Program, Automation Long-Term Planning and SCADA Bundling Initiatives & Unit Cost strategies.