The Challenge

Large utilities maintain hundreds of substations with multiple transformers at each site. On site inspections cost utilities time, travel and they often must take planned outages to make sure the inspection can be done safely. It may take years for a utility to get through their whole fleet and by the time they do, its time to start the process again. These single point in time inspections can miss problems that can crop up in between the inspection cycles. With the advancement of sensor and communications technology, utilities can economically install automated, continuous monitoring systems to improve safety, reduce costs due to manual inspections and increase the early detection of potential failures.

Background

Southern Company’s goal was to find a way to extend on-site transformer inspection cycles more than 200% by deploying a remote monitoring solution that could provide transformer health data on a continuous basis. They were already deploying online Dissolved Gas Monitoring and Bushing monitoring, but a gap existed with the lack of infrared monitoring. Instead of doing periodic on-site visual and thermal checks, Southern Company wanted to have up to date and continuous information on the health of their transformers. Southern Company identified all the points on the transformer they wanted to monitor with the intent of integrating the thermal data into their Condition Based Maintenance system. Due to the large number of transformers to be monitored, Southern Company wanted to minimize the sensor installation time and complexity so the project could be rolled out as quickly and economically as possible. The goal was a product that would enable two men to install the system on multiple transformers in one day without an outage.

Project Requirements

Southern Company had clear ideas about the solution they wanted to implement to achieve their goals of optimizing maintenance plans.

Thermal Monitoring of Critical Points – the maintenance team identified the critical points on the transformer that they wanted to thermally monitor. A thermal sensor could monitor multiple transformer subsystems and do the job of individual, specialized sensors. It had to provide continuous temperature monitoring of these points to provide an asset health profile of the transformer and its subsystems.

Ease of Installation – due to the number of transformers that Southern Company planned to deploy the monitoring system on, they needed an installation that didn’t require digging for poles or cables. Substation excavations are time consuming and costly, so the mounting system had to self-supporting, be powered from the AC or DC supply already present inside the transformer wiring compartment and the sensor had to have wireless communication and low power consumption. Due to the strong storms that pass through the region, the mounting system had to withstand up to Category 2 winds.

Network Security – the sensor, cloud dashboard and data storage had to be secure and isolated from the Southern Company network. The equipment provider had to pass a comprehensive third-party vendor risk assessment for data security and application change management.

Data Integration – the data gathered from the sensor had to be integrated in the OSIsoft Pi system so it could be tied in with Southern Company’s asset management, operations, and maintenance applications.

The Solution

The IM500 Module is an IoT sensor with onboard thermal and visual imagers and built-in wireless communications. An IM500 takes temperature readings on live systems and will detect overheating bushings, lightning arresters, load tap changers, cooling systems, main tank and other transformer subsystems. Due to its small size and low power requirement, the IM500 can be installed quickly in areas to provide optimal line of site monitoring.

Systems With Intelligence worked closely with Southern Company to develop an IM500 mounting system for their transformers. The mounting system attaches directly onto the body of transformer with industrial strength magnets that are rated to withstand the operating temperatures of a power transformer. The system is designed with high strength fiberglass and a series of adjustable clamps that allow easy positioning and quick installation. The mounting system coupled with Southern Company’s safety work rules enabled the installation on an energized transformer.

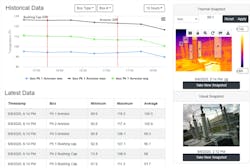

The IM500s are pre-programmed to take snapshots that give operators a visual and thermal view of the critical transformer subsystems. The thermal data is collected, stored and analyzed on a continuous basis. The connection to the SWI Cloud is authenticated and encrypted to ensure the safety and security of access to the device and data. The Systems With Intelligence dashboard provides a comprehensive view of the data providing graphs of the temperature points along with visual and thermal images. Alarms can be set in the dashboard with automated email alerts so operators and maintenance experts are alerted instantly if temperatures exceed the pre-set thresholds. The data and alarms can be retrieved directly from the SWI Cloud, allowing the utility to trend the data and use it in a condition-based maintenance program.

Summary

The IM500 allows Southern Company to perform remote, TouchlessTM Inspections, with 24/7 monitoring on sites and equipment that would otherwise be time consuming and costly to inspect. The IM500 provides visual and thermal imaging, providing continuous and up to date health information on multiple transformer subsystems. The IM500 installs quickly and easily with the transformer Quick Mount, low voltage requirements and built-in communications. Temperature data is integrated with OSIsoft PI for further analysis, trending and input to asset management applications. Continuous thermal monitoring ultimately improves utility safety and reliability while reducing maintenance costs.

For more information contact us at [email protected], or visit our website at www.systemswithintelligence.com.

Sponsored by: