A Gas-Insulated Substation Can Be Green And Digital

Prompted by requests for capacity from distributed energy resources, Stedin sought to develop a green and digital gas-insulated substation. The Netherlands distribution system operator supplies most of the Randstad area, which includes the cities of The Hague, Utrecht and Rotterdam, the Port of Rotterdam area and the Botlek industrial area. These are high-density urban areas with a complex infrastructure and a high dependency on energy. Conversely, Stedin also supplies energy to low-density urban areas, which have a high penetration of distributed energy resources (DERs). All these areas require continuous availability of energy, now and in the future.

The initial aim of Stedin’s Middelharnis II green and digital gas-insulated substation (GIS) project was to expand an existing substation with an additional 50-kV section in a sustainable and innovative way. However, the utility also wanted to reduce its carbon footprint, so it ultimately decided to ban the use of SF6. This changed the utility’s goals for the 50-kV GIS project.

The first goal was to replace the use of SF6 with green gas for grid (g3), which has an impact of less than 99% on the global warning potential (GWP) compared to SF6. A second goal was to innovate in the digital substation by installing low-power instrument transformers (LPIT) as sensors instead of conventional sensors that use large quantities of steel and copper. As a result of this decision, Stedin has been able to obtain more modeled, useful data out of the substation through the IEC 61850 standard used for the interface of the LPIT measured values.

Applying LPITs

For Stedin, the digital substation is a key element of the operating system in the smart grid, by making it possible to improve network management and predict the cost of the energy transition. The utility believes digital substations will become indispensable for business and operational processes, as all data from the high-voltage, medium-voltage and low-voltage networks can be combined and used to optimize the energy supply system.

When using LPITs, a stable standard must be used to exchange the measured values, to ensure system reliability and create a vendor-independent ecosystem. For this project, Rogowski coils and capacitive dividing technologies were used. Although not a new principle, interoperable multivendor setup was not easily achievable for Stedin until the IEC 61850-9-2 and IEC 61689-9 standards were released. These standards clearly and concisely describe which measured value streams are used, and this information enabled Stedin to start applying LPITs.

In the Middelharnis II project, three feeders are equipped with LPITs as follows:

- Outgoing 50-kV feeder is connected to an adjacent 50-kV substation with line differential protection that combines the LPIT (Middelharnis II) with a conventional current transformer (CT) and merging unit installed in the adjacent substation.

- Transformer feeder is connected to the 50/13-kV transformer. The transformer differential protection is a combination of LPIT (50 kV) and conventional CT through a merging unit connected to an intelligent electronic device (IED) without a merging unit.

- Bus bar voltage creates a synchro-check function with the combination of the LPIT and a conventional voltage transformer (VT) between bus bars.

Green & Digital

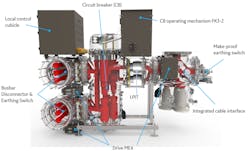

The GIS product installed in the Middelharnis II project is an SF6-free solution based on a mixture containing fluoronitrile CO2 and O2, commonly referred as g3. An environmentally friendly alternative gas mixture to SF6, g3 was developed for high-voltage transmission equipment. The GIS in Middelharnis II has the same ratings footprint as state-of-the-art SF6, but with a drastically reduced environmental impact of more than 99% less gas GWP. Also, g3 products operate with no restriction under the same temperature range as SF6 products, namely down to -25°C (-13°F).

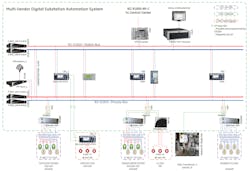

On the digital side, the basic building block is the IEC 61850 process bus and the concept of distributed in/out (I/O) for protection and supervisory control and data acquisition (SCADA) reporting. Implementing the process bus in a GIS converts the current and voltage measurement to digital messages by using the LPIT directly. The general concepts of IEC 61850 process bus network architecture simplify control and protection testing, posing less risk than with a conventional GIS.

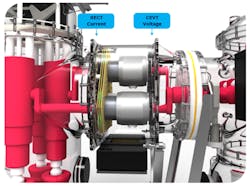

Standard GIS today use conventional CTs and VTs for analog measurement. To digitalize a brownfield GIS, an analog merging unit (AMU) is installed to convert the analog current and voltage measurement to digital messages. However, for a greenfield project where a new GIS will be installed, the LPIT offers state-of-the-art technology and improvement. The two major principles used in GIS LPIT are the Rogowski and capacitive technologies, namely Rogowski electronic current transformer (RECT) and capacitive electronic voltage transformer (CEVT).

Measured Values

For the measurement of currents, the Rogowski sensor used in the Middelharnis II GIS is manufactured on a printed-circuit board (PCB), as the nonmagnetic material is the main driver for achieving a reliable and predictable sensor that can reach a perfect homogeneity of the windings. It offers stable and outstanding accuracy and linearity measurement. The sensor is not sensitive to environmental factors, so a unique sensor is used for the metering application with rated currents ranging from 100 A rms to 5000 A rms. The same unique sensor also can acquire, without saturation, large fault currents up to 63 kA rms with full asymmetry.

The CEVT also is designed in a double-sided PCB as a ring electrode near the enclosure. The CEVT provides advantages like long-term stability, no partial discharges, extremely high thermal stability and tolerance to primary conductor vibrations. The CEVT and RECT can be installed in a stand-alone or combined mode.

The CEVT and RECT sensors are connected to a primary converter (PC12) that converts the primary signal in a digital frame to the XMU (LPIT merging unit), which subsequently gives the process bus digital output of IEC 61850-9-2 sampled value streams. The process bus sampled value streams can be used by all process bus applications. In the Middelharnis ll substation, PC12 has been installed on top of the embedded cubicle on the GIS for easy access.

Engineering Process

The heart of a digital substation solution is the network system architecture. Installing the same communication protocol IEC 61850 throughout the whole substation lowers the costs for maintenance, installation and operation as well as provides faster communications.

Network devices that manage real-time data exchange for protection and control applications will satisfy high-level system requirements — since their failure could impact those applications. Thus, to warranty the safety and performance, the solution relies on high-availability automation networks defined by the IEC 62439-3 standard, which specifies two redundancy protocols — the parallel redundancy protocol (PRP) and the high-availability seamless ring (HSR) — for double-star and dual-ring architectures. In the Middelharnis II project, PRP architecture has been selected at both the station level and process level to provide a safe, highly interoperable and reliable network architecture.

To yield the highest accuracy and granularity from such protection and control applications, the use of a common, precision-time reference is mandatory. Hence, the system heartbeat is addressed by the IEEE 1588 precision time protocol (PTP) standard, which synchronizes clocks throughout the network by achieving clock accuracy in the sub-microsecond range, making it suitable for protection and control systems. The primary time source relies on time broadcast by atomic clocks from a dedicated time server within the substation, called the grandmaster clock (GM). It receives the time signal from the outside. GNNS, GPS and GLONASS satellites provide the highest accuracy.

Configuration of an IEC 61850 substation at the system level is a comprehensive engineering process and even more so with the process bus. It not only involves IED configuration tools and a system configuration tool, but it also requires a correct understanding of the configuration process and data flow. The focus on the configuration tool is to provide a comprehensive solution — to manage from configuration to device deployment — to guarantee project execution by means of an integrated process.

IEC 61850 is a standard that provides methodology and modeling of substation automation systems. Based on this process, Stedin’s approach to the configuration was to model the system using the object-oriented method.

Pilot Project

Stedin conducted a pilot project on its new green and digital GIS to demonstrate and test new technologies as well as benefit from operational experience.

The most important requirements for the protection, automation and control system were as follows:

- Multivendor solution

- All data in the IEDs should be accessible by an IEC61850-90-2 gateway

- The possibility of having LPITs on one end and conventional instrument transformers for the distance protection and differential protection schemes at the remote ends.

To complete the system, monitor and diagnosis (M&D) equipment installed on the 50/13-kV transformer was integrated in the protection, automation and control system. The M&D system monitors the dissolved gas analysis (DGA) protection and enables Stedin to observe the condition of the transformer on-line.

An important topic during the testing and commissioning procedures was how to test the LPITs, as the simple secondary injection testing of currents and voltages is not possible. However, the primary converter is equipped with a dedicated test input that makes it possible to test the converter as well as the merging unit up to the process bus in a safe manner. Furthermore, it is important to know that testing of individual IEDs connected to the process bus also can be completed easily and safely. However, if undertaking this procedure on-line, the protection no longer functions on primary values and tripping will not occur in the event of a fault.

Project Observations

The Middelharnis lI project has demonstrated the potential offered by digital substations, and it is evident to Stedin that digital is the future. Real and fully digital substations can be realized both easily and efficiently. It will require additional skills in return for the increased benefits, which were anticipated and fulfilled in the Middelharnis ll project.

The application of an LIPT chain requires clearly specified accuracy classes and requirements for each device. Furthermore, replacement parts of this chain must be the same and subject to intensive testing.

Unexpected was the skill competency of the existing personnel, who were used to installing and testing conventional CTs and VTs. With the introduction of LPITs and process bus, personnel training will be a necessity. Also, equally important is time synchronization. Without accurate time synchronization, the protection functions will fail to operate correctly.

Differential protection comprising different source types leads to phase differences. This needs adjustment in the protection devices and is still quite an undiscovered topic.

Finally, promotional material from some vendors claim that their products are IEC 61850-9-2 compliant. In practice, this is not always the case. Fortunately, in the market, there are a relatively large number of vendors whose products are compliant with this standard.

Stedin is on a mission to create an environment filled with new energy. More and more of its customers are generating sustainable energy, and the utility must be adequately prepared to implement the latest technologies. Together with stakeholders, Stedin is developing a sustainable energy system that will be reliable and affordable in the long term.

Acknowledgement

The authors wish to acknowledge the technical support and advice received from Bruno Castagne and Jacques van Ammers of General Electric in the preparation of this article.

René Troost graduated as an electrical engineer and started his career in telecommunications. In 2014, he joined Stedin. With extensive experience and expertise in the protection, automation and control domain, Troost is currently responsible for substation automation policy and an active member of the Dutch Committee of the IEC TC57 (NEC57) and the CIGRE Technical Committee 57 WG10, which deals with power system intelligent electronic devices, communication and associated data models.

Pascal Eversteijn graduated as an electrical engineer and started his career in 2009 with Stedin in the area of protection relays. After a few years, his work extended to secondary equipment for protection, automation and control. In this domain, Eversteijn is responsible for managing the areas of Dordrecht and Goeree-Overflakkee. He participated in several tenders for protection, automation and control systems and telecommunication and has been involved in innovative pilots involving these systems.

About the Author

René Troost

René Troost ([email protected]) graduated as an electrical engineer and started his career in telecommunications. In 2014, he joined Stedin. With extensive experience and expertise in the protection, automation and control domain, Troost is currently responsible for substation automation policy and an active member of the Dutch Committee of the IEC TC57 (NEC57) and the CIGRE Technical Committee 57 WG10, which deals with power system intelligent electronic devices, communication and associated data models.

Pascal Eversteijn

Pascal Eversteijn ([email protected]) graduated as an electrical engineer and started his career in 2009 with Stedin in the area of protection relays. After a few years, his work extended to secondary equipment for protection, automation and control. In this domain, Eversteijn is responsible for managing the areas of Dordrecht and Goeree-Overflakkee. He participated in several tenders for protection, automation and control systems and telecommunication and has been involved in innovative pilots involving these systems.