The Future is a Touchless Substation

Over the next decade, the introduction of distributed resources and an increase in customer expectations will require utilities, public utility commissions and other stakeholders to reinvent the electric power value chain. The objective of PSE&G’s touchless substation initiative is to implement technologies, processes, and methodologies to eliminate or minimize the need to regularly visit a substation, making it truly touchless.

Through this initiative, PSE&G will evaluate and effectively deploy technologies that help to lower operation and maintenance (O&M) costs, by reducing the need to inspect a substation physically. Inspections will be facilitated by an analyst responsible for continuous monitoring of the utility’s assets using technology to assist in repair, replace or maintain decisions. The investments will enable PSE&G to retain reliability, reduce safety concerns and increase visibility into its substation.

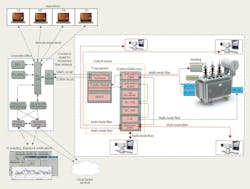

Integration of touchless substation components in existing PSE&G SCADA and fiber systems.

Why Target Substations?

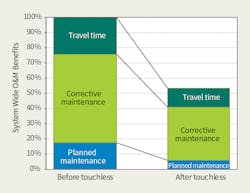

Substations are a utility’s most critical and expensive asset. At PSE&G, they require periodic manual inspections with calendar-based maintenance programs to ensure the health of station and associated assets. Today’s O&M substation expenditures include a significant amount of travel time to perform planned maintenance, with travel costs at almost 20% of total O&M costs. In today’s world, planned maintenance is diagnostic testing. Physical work and corrective maintenance are performed only when a problem is found.

Implementation of touchless substation systems will eliminate many of the visual inspections and diagnostic tests performed on a periodic basis. These systems will bring in test data to PSE&G’s computerized maintenance management system (CMMS), where repair, replace or maintain decisions can be made consistently across the asset inventory.

Touchless substations are expected to reduce system-wide O&M costs significantly.

Why Invest?

A touchless substation will reduce calendar-based maintenance work orders and associated travel costs. The use of remote diagnostics enables more time for a planned response and visibility into the substation. Additional savings would be realized with corrective maintenance, by lengthening future maintenance cycles as a result of more advanced asset management tools. Benefits to the asset management process are tangible with automation through generated reports and meaningful advanced analytics to determine plans of action.

Extracting insights and actionable information from data requires a broad array of solutions that can work with data efficiently and cost effectively. PSE&G intends to use cloud-based platforms such as Amazon Web Services for storage of nonoperational data. Cloud services is the on-demand delivery of computing power, database storage, applications and other information technology resources through an internet platform with pay-as-you-go pricing. Benefits of cloud services include cost savings through economies of scale and eliminating the need to invest in the O&M of data centers.

Touchless substation data requires the development of an analytics platform to enable asset management decisions. The analytics process chain includes data warehousing, business intelligence, batch processing, stream processing, machine learning and data workflow orchestration. Machine-learning enhanced models will be used to drive prescriptive analytics and failure predictions as part of the asset management process. Currently, live dashboards are developed to provide visibility on asset health and status on major equipment monitored using the OSIsoft PI system.

PI Asset Framework analytics is used for developing algorithms that provide insight into the current health of the asset. Adding more capabilities for remote monitoring enables the development of real-time displays, providing a replica of the substation to field operations, engineering and management with a click of a button.

Building Blocks

PSE&G has been aggressive over the last 15 years by installing fiber optics where possible, replacing electromechanical relays with microprocessor relays, and installing advanced transformer monitoring when replacing and rebuilding stations. Transformer monitoring brings fiber-optic communications throughout the substation location, enabling the addition of more advanced devices at a relatively low cost per unit.

With monitoring and communications in place, the addition of bushing monitors, gas and oil analyzers, and visual and infrared cameras become cost effective. Opportunities are available to install advanced monitoring technologies concurrently with rebuilding of substations as part of PSE&G’s proposed Energy Strong II portfolio. The incremental cost to implement touchless substations will be far less for Energy Strong II substations. The utility has the infrastructure in place to reduce many of the upfront costs associated with its touchless substation initiative.

Placement of thermal and visual cameras in typical PSE&G air-insulated switchgear substation.

Transformer Monitoring

Transformer monitoring was initiated based on the need to increase the sampling rate for conditioned-based data on transformers. This originated about 10 years ago when PSE&G was rebuilding its transmission system. It required installing the SEL-2414 from Schweitzer Engineering Laboratories to monitor and communicate transformer diagnostic data across the utility’s newly installed nonoperational data path. This had a limited impact on North American Electric Reliability Corporation (NERC) requirements because control devices could not be handled. However, adding bushing monitoring to the current configuration would be relatively easy and cost effective.

Today, all transformers procured by PSE&G are delivered with monitoring equipment already installed, and they are connected to the nonoperational data path. The transformer monitoring equipment integrates temperature sensors, level sensors and pressure sensors, but it has no control capabilities. The combination of these sensors, the monitoring system, the development of algorithms and advanced transformer analytics facilitates hot-spot and loss-of-life calculations. It also determines insulation aging acceleration factors and allows for thermal and through-fault monitoring, while generating hourly and daily data about the transformer. Additional features and functionality built into the transformer monitoring equipment makes it easy to integrate it with new and retrofit transformer monitoring applications.

Implementation

PSE&G currently is deploying image capture and visual analytics technologies in one of its substations as a next step in the journey toward a touchless substation. When determining the station type that would be used as a proof of concept, the utility decided the proposed initiatives would be best suited for a class of substation with the largest inventory.

PSE&G has almost 100 stations where 230-kV transformers step down to 13-kV distribution. These stations have large transformers (60 MVA) with air-insulated buses and associated distribution switchgear. This typical air-insulated switchgear (AIS) station has high value assets, basic monitoring systems, supervisory control and data acquisition (SCADA) as well as a nonoperational data path for diagnostic data collection.

Visual and Bushing Monitoring

The proof-of-concept project involves increasing both optical and thermal visibility within the substation. A multiple-camera system was installed that includes both visual and thermal imaging sensors to monitor visual aspects of substations along with heat patterns. The visual imaging sensors provide real-time remote visibility into the substation, enabling intruder detection and asset condition assessment as well as helping to identify abnormal conditions or events that occur within the station. The camera system also will add an additional layer of physical security to prevent theft and vandalism.

The thermal imaging sensors can monitor the thermal condition of major equipment in the substation and will be able to track rates of change or absolute increases digitally. Providing a live and intelligent feed to analysts will enable proactive condition assessments and timely resolutions to abnormalities. All imagery will be analyzed remotely by the analyst before issues become major failures.

Moving toward the truly touchless goal, existing transformer monitoring systems will be augmented with transformer bushing monitoring equipment. Solutions provide insights into degradations of a key component of transformers and extract correlations between transformer monitoring and bushing monitoring trends. Substation transformer bushings contribute 17% to the total failure rate of transformers and more than half are catastrophic, according to Cigre Working Group A2.37’s “Transformer Reliability Survey: Interim Report” published in No. 261 - April 2012 of ELECTRA. With the implementation of a bushing monitoring system, multiple-defect phenomena can be detected through monitoring parameters of capacitance, tan delta and partial discharges.

Battery Solutions and Breakers

Implementation of battery monitoring systems meeting NERC standard PRC-005-06 will obtain real-time data and alerts when batteries are outside tolerance. Currently, batteries and chargers are tested yearly where inspections of charger current, voltage, station direct-current load, ground condition, the electrolyte level, and the condition of battery cells and rack are recorded. The battery monitoring system will avoid current practices by employing automated discharge testing to be completed regularly and the use of cameras to monitor water levels. The overall condition of the battery can be assessed remotely, and the need to perform any repairs or replacement (on the jar or entire battery) will be identified seamlessly.

Currently, breakers at PSE&G are inspected through planned maintenance activities or corrective maintenance repairs when a problem is found. Leveraging breaker relay data to the developed analytics platform through fiber and SCADA will enable condition-based maintenance and measurement of breaker performance at a relatively low cost. Drivers for circuit breaker health and condition are mechanical condition, interrupter wear and timing. Trip and close data will be used to detect mechanical problems during circuit-breaker operation. Calculations of energy the breaker has been subjected to (I2T) can be measured over the life of the breaker and used to estimate contact wear. When compared to asset inventories, these data points will drive repair, replace or maintain decisions.

Benefits

These diverse and complementary technologies will enable PSE&G’s asset management team to make more informed condition-based decisions, give operations team members remote visibility into substations and reduce physical inspections. The systems will provide additional real-time remote visual and thermal opportunities once deployed. The benefits of integrated touchless substation systems will be realized by a reduction in O&M expenditures for manual inspections and calendar-based maintenance activities by prioritizing maintenance based on data, not time.

If all systems are in place, then a savings up to 50% in O&M expenditures could be realized. Additional benefits are the extension maintenance cycles using prescriptive analytics and failure predictions. Work efforts will be streamlined by performing the right maintenance at the right time and re-

mediating problematic equipment, resulting in reduced failure rates. Touchless substation solutions provide improvements to the asset management process through improved visibility of key assets by continuous monitoring, enabling just-in-time response.

For more information:

OSIsoft | www.osisoft.com

PSE&G | www.pseg.com

About the Author

Dennis O’Rourke

Dennis O’Rourke is a project staff engineer in electric delivery planning at PSE&G. He handles analysis of distribution system reliability, initiation and integration transmission lifecycle and distribution reliability projects. He has served in several engineering roles within the Asset Management and Centralized Services at PSE&G. He has a BS in mechanical engineering and a MS in engineering management from New Jersey Institute of Technology.

Raymond C. Alvarez

Raymond Alvarez, PE, PMP is a senior director of PSE&G’s Electric Asset Management. His responsibilities include transmission and substation engineering, NERC compliance, and system reliability. Prior to joining PSE&G in 2009, he served as vice president of Critical Systems, building and managing critical infrastructure facilities banking and data center clients. He started his career at Con Edison, where he served in Generation, Engineering, Electric System Operations, Construction, Customer Operations and Project Management. He holds a BSEE from Rutgers University, and a master’s degree in Power Engineering from New Jersey Institute of Technology.

Masroor Khan

Masroor Khan is an engineer within the Electric Asset Strategy group at PSE&G. Her responsibilities include maintaining the Computerized Maintenance Management System (CMMS) and contributing to smart grid technology. This includes creating numerous data points, analytics, notifications, and visual displays in CMMS from various sources that include transformer monitoring equipment, gas density monitoring equipment, and SCADA. Other responsibilities include condition-based maintenance, building interfaces in CMMS, and asset health scoring. Masroor has a BS in civil engineering and a MS in engineering management from New Jersey Institute of Technology (NJIT).