Engineering Automation Drives Decision Making

The information age has had a transformative effect on business and society, and the electric utility industry is no exception. New technologies in databases, monitoring hardware and control systems have put an unprecendented amount of data at the fingertips of utility engineers, planners and operators. The tools and processes to effectively manage and use this data historically have been underdeveloped, resulting in data sets being limited to single applications rather than leveraged across an organization. These data silos and incompatabilities between applications exemplify the modern adage of data rich and information poor (DRIP).

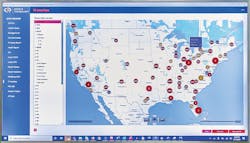

Today, software-based automation tools and applications have enabled utilities to manage vast quantities of data as well as integrate disparate processes around that data. As a result, utilities can maximize efficiencies and the capabilities of engineering resources significantly. This shift in focus from specific use cases to a more holistic use of data can help utilities to meet the emerging challenges of the modern power industry.

San Diego Gas & Electric (SDG&E), a Sempra Energy utility, is one of the organizations at the forefront of this paradigm shift. Over the past five years, SDG&E’s System Protection Automation and Control Engineering (SPACE) department has worked closely in partnership with Quanta Technology LLC to implement software-based solutions to improve processes and data handling for various aspects of T&D system protection and control. This five-year program is a collective of individual data-driven improvement projects, each targeting a specific task or responsibility of SPACE department engineers. Although the individual efforts may have started as separate projects, each was designed with the goal of enabling SDG&E to effectively manage and use its data in automated and integrated processes across the enterprise.

Automation And Integration

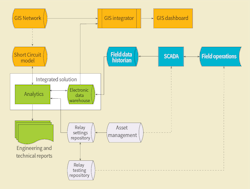

The solutions implemented within the SPACE department were software applications that automated tasks and integrated data sources to address specific functions and responsibilities of SPACE team engineers. The following applications and processes were developed:

- Protection data investigation and consolidation of multiple sources to enable easy utilization in a single protection settings repository for future applications

- Automatic generation of protection data summaries to meet internal reporting requirements

- Automated modeling of protection representation in short-circuit software through direct connection to the relay settings repository

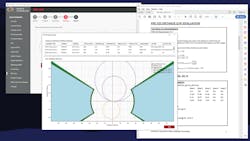

- Evaluation of North American Electric Reliability Corporation (NERC) reliability standards through analysis of protection and system data as well as automatic generation of formal reports for compliance documentation

- Determination of personal protective equipment (PPE) safety requirements through comparison of equipment ratings with distribution protection settings data

- Analysis of near-real-time load data and protection settings to determine permissibility of enhanced-sensitivity protection during periods of high fire danger.

These projects stemmed from engineering personnel facing increased workload. New requirements in compliance, the deployment of novel technologies and increasing vulnerability to wildfire danger all required significantly more effort from the SDG&E workforce. To address these concerns while maintaining the highest safety standards, the SPACE team sought to explore innovative methodologies to fulfill their responsibilities. Effective utilization and management of available data in automated and integrated processes was seen as a promising means for engineering personnel to address their workload concerns.

Originally, the scope was limited to specific tasks and requirements that individual applications were intended to address, such as a process for efficiently evaluating the NERC PRC-023 compliance standard. As the benefits of these projects became more apparent, the goal shifted from addressing individual tasks to transforming SDG&E’s processes to fully integrate multiple data sources through automated applications. SDG&E worked closely with Quanta Technology to implement each individual application not only to meet the specific needs of a project but also to design each component for future interoperability and compatibility between data processes.

Implementation Challenges

Although software-based automation and integration applications offer benefits in reliability, consistency and task completion efficiency, SDG&E found the actual implementation of these solutions across teams with existing and disparate data processes had its own challenges. In particular, considerations for data quality and availability, engineer acceptance, and process maintenance and infrastructure were addressed throughout this data process improvement program.

Data format and availability were important considerations for reliable utilization of data. Because the implemented applications were largely automated, technical data quality — such as format standardization — was critical for each application. Furthermore, missing data would be a significant impediment to the operation of automated processes. Data quality and availability concerns were addressed through consolidation, digitization and standardization efforts to ensure a suitable foundation for the successful deployment of automated applications and future initiatives.

Engineer acceptance was a key requirement for the successful implementation of multiple automated processes within the SPACE department. This was facilitated through a strategy of incremental improvements, where changes to existing data processes and requirements were introduced gradually across multiple projects, as practical. Foundational improvements, such as the consolidation of protection settings in a settings repository, were undertaken early in the program.

As a result, subsequent projects, such as the analysis of protection settings data with other sources, were made feasible by leveraging these earlier efforts. This gave engineers confidence in the technical capabilities of the new processes. Subsequent projects were pursued after engineers had become accustomed to the concept of automated processes and the requirements of maintaining data.

Process maintenance and infrastructure were crucial considerations to enable the continued operation of automated processes. Key success factors included staff training, tool maintenance and infrastructure support. For the long-term success of any automation or data-driven application or process, understanding data entry and format requirements to maintain the processes and applications is paramount. Staff training heavily emphasized the need to maintain data in standardized formats and correct locations to ensure compatibility with the deployed software solutions.

Because power systems generally are not static, the deployed applications and processes were designed with maintenance and updatability in mind. Depending on the task to be addressed by an application or a process, the following are some crucial potential updates:

- Addition of new relay types, requiring updating the logic engine to enable interpretation of protection settings and

operation. - Connection to new data sources, requiring modification of expected standardized formats to enable compatibility with the new sources.

- New evaluation or comparison criteria, requiring updates to not only the computation engine but also the interface and reporting outputs.

Finally, change management for future refinements, utilization and access considerations, and documentation were key components of the overall program. Change management included developing internal procedures for identifying and discussing the need for updates to the deployed applications and processes as well as the tracking mechanisms to manage different revisions.

The utilization and access considerations covered the integration of these new solutions in existing processes, including when they should be used and by whom. This is especially important for applications that permanently change properties in shared resources, such as updating protection representation in the short-circuit model. SDG&E uses a check-in and check-out procedure for the short-circuit model when protection updates are made to ensure clear continuity of the record.

These considerations along with the updatable design of the applications and processes give the SPACE department flexibility and traceability as adaptions are made to address emerging and future requirements.

Toward The Future

The partnership between Quanta Technology’s engineering automation group and SDG&E’s SPACE team has driven improvements in nearly every function of the department’s tasks and responsibilities. Each new solution over the last five years was considered for its role and placement within a long-term vision for a more responsive and effective SPACE department.

The deployment of these engineering automation solutions brought several important benefits to the SPACE team:

- Mitigation of the risk of user error in manual data transposition and calculation.

- Reduction in time required to complete engineering studies and data analysis.

- Ability to automatically generate consistent, accurate documentation to meet regulatory audit and internal requirements.

- Shifting of valuable personnel resources from performing repetitive data-related tasks to efforts that require more problem solving and the application of knowledge.

Throughout this program, several key lessons were learned while overcoming challenges in the deployment of automated applications and processes:

- Data standardization and consistency is critical for reliable utilization of deployed applications and processes. Data governance procedures, comprised of both training and putting controls in place, can be effective measures in maintaining data compatibility.

- Engineer acceptance is critical to the successful long-term use of new tools, particularly those based on automation. The incremental introduction of projects enabled engineers to become accustomed to automation solutions and requirements, and transparent design helped engineers to gain confidence in applications on a technical level.

- The design and utilization of engineering automation solutions need to be carefully considered in terms of the tasks they address and integration with existing practices. Excessively restrictive or open designs can lead to challenges with engineer acceptance, standardization and focus. Design and operational processes should be aligned with the capabilities and size of the engineering team.

The existing program has demonstrated the ample benefits of engineering automation concepts within the SPACE department and given the team more confidence in the feasibility of seamless data transfer between sources. The implemented initiatives represent the tools and processes needed to effectively manage and use data. They serve as a solution for the DRIP dilemma, which previously was a barrier to leveraging the benefits of data availability. Building on the success of this program, the scope may be expanded to include additional data sources from other departments, outside SPACE, to further tie SDG&E’s processes and tasks among operational units.

The overall goal of engineering automation is to shift the focus of utility personnel from handling data compatibility and translation to making engineering decisions. Ultimately, these automation solutions link engineering, operations and planning business units of utility organizations, promoting a seamless flow of data between historically disparate applications and business units. This change in paradigm — from focusing on individual applications to developing a unified vision, exemplified by SDG&E’s five-year (and continuing) data process improvement program — brings significant benefits in process efficiency, accuracy and resource allocation.

Ultimately, engineering automation not only improves safety and reliability but also enables utilities to meet the challenges of the 21st century.

Tim Chang works in the engineering automation group at Quanta Technology, where has worked since 2009. His experience ranges from traditional T&D engineering applications to use of real-time digital simulation for advanced renewable impact studies. Chang has been a major contributor to the development of automated processes and applications for data management and engineering studies, including evaluation of NERC compliance standards, and software modeling solutions. He earned his master’s degree from the University of Toronto.

Saman Alaeddini leads the engineering automation team at Quanta Technology, where he has worked since 2009. His team has developed many innovative software-based solutions for the power systems industry, particularly in the area of NERC compliance evaluation. Alaeddini is a specialist in protection system modeling, database management and analysis, autonomous systems design, robotics and industrial processes. His experience includes real-world automation system implementation and maintenance, and advanced data analytical techniques. He earned his master’s degree from Ryerson University.

Damir Novosel is president and founder of Quanta Technology. Previously, he was president of Quanta Energized Services, vice president of ABB Automation Products, and president of KEMA T&D US. Novosel is a member of the U.S. National Academy of Engineers and CIGRE U.S. National Committee. He served as IEEE PES president and is a member of the IEEE Standards Board and chairs the IEEE Smart Cities and Industry Technical Support Leadership Committee. Novosel holds 18 patents, has over 170 publications and has contributed to five books.

Christopher Bolton is manager of system protection automation and control engineering at SDG&E, where he has worked since 2011. Bolton has held a variety of positions with the utility, including in substation engineering, capital projects, substation technical analysis and support, and system protection maintenance. Bolton graduated with a BSEE degree from California State Polytechnic University, Pomona and is a licensed professional engineer in California.

Ahsan Mirza is manager of system protection maintenance at SDG&E. He manages a team of relay technicians and SCADA technicians responsible for the utility’s T&D relay construction and maintenance. Prior to his current role, Mirza was a team lead in system protection automation and control engineering for five years. He joined SDG&E in 2009 after receiving his BSEE degree from University of Illinois in Urbana-Champaign. He is a registered professional engineer in California.

Sergio Flores Castro is team lead for distribution system protection and automation at SDG&E. He joined the utility in 2013 as an associate engineer with rotations in smart grid, district engineering and system protection. He earned his BSEE degree from the University of Nevada, Las Vegas in 2012 and a certificate in power systems from the University of California, San Diego in 2016. He is a registered professional engineer in California.

About the Author

Tim Chang

Tim Chang works in the engineering automation group at Quanta Technology, where has worked since 2009. His experience ranges from traditional T&D engineering applications to use of real-time digital simulation for advanced renewable impact studies. Chang has been a major contributor to the development of automated processes and applications for data management and engineering studies, including evaluation of NERC compliance standards, software modeling solutions, wide-area protection coordination studies and line constants calculations. He earned his master’s degree from the University of Toronto.

Saman Alaeddini

Saman Alaeddini leads the engineering automation team at Quanta Technology, where he has worked since 2009. His team has developed many innovative software-based solutions for the power systems industry, particularly in the area of NERC compliance evaluation. Alaeddini is a specialist in protection system modeling, database management and analysis, autonomous systems design, robotics and industrial processes. His experience includes real-world automation system implementation and maintenance, and advanced data analytical techniques. He earned his master’s degree from Ryerson University.

Damir Novosel

President

Damir Novosel (SM 1994, F 2003) is president of Quanta Technology, a subsidiary of Quanta Services. Previously, he was vice president of ABB Automation Products and president of KEMA T&D U.S. Damir was elected to National Academy of Engineers in 2014.

Dr. Novosel is IEEE PES President-Elect. He served as chair of the PES Technical Council, vice president of technology, and a member of the PES Governing Board from 2010 to 2012. Damir is also member of the CIGRE U.S. National Committee.

Damir holds 16 U.S. and international patents and published more than 100 articles in transactions, journals and proceedings, receiving PES 2011 and 2013 Prize Paper Awards. He has led or participated in numerous IEEE standards, publications and other initiatives, such as keynotes and panels.

Damir has been continuing contributor to education, including an adjunct professorship of Electrical Engineering at North Carolina State University, sponsorship of college scholarship programs, and support to industry courses and tutorials.

He holds PhD and MSc degrees in electrical engineering from Mississippi State University, where he was a Fulbright scholar, and the University of Zagreb, Croatia.

Chris Bolton

Christopher Bolton is manager of system protection automation and control engineering at SDG&E, where he has worked since 2011. Bolton has held a variety of positions with the utility, including in substation engineering, capital projects, substation technical analysis and support, and system protection maintenance. Bolton graduated with a BSEE degree from California State Polytechnic University, Pomona and is a licensed professional engineer in California.

Ahsan Mirza

Ahsan Mirza is manager of system protection maintenance at SDG&E. He manages a team of relay technicians and supervisory control and data acquisition technicians responsible for the utility’s T&D relay construction and maintenance. Prior to his current role, Mirza was a team lead in system protection automation and control engineering for five years. He joined SDG&E in 2009 after receiving his BSEE degree from University of Illinois in Urbana-Champaign. He is a registered professional engineer in California.

Sergio Flores

Sergio Flores Castro is team lead for distribution system protection and automation at SDG&E. He joined the utility in 2013 as an associate engineer with rotations in smart grid, district engineering and system protection. He earned his BSEE degree from the University of Nevada, Las Vegas in 2012 and a certificate in power systems from the University of California, San Diego in 2016. He is a registered professional engineer in California.