The energy market transformation to distributed generation is happening rapidly. Renewable energy sources such as wind, solar and biogas are ever increasing in the generation mix. It is now estimated total distributed generation installed capacity will reach 1182 GW by 2030, accounting for 10% of the global installed power generation in the year, according to Frost and Sullivan.

The existing electrical infrastructure cannot accommodate the vast connection of distributed energy resources because of the increasing fault current level from these new sources. If the fault current is too large and exceeds the distribution network equipment ratings, utilities face the risk of equipment damage and power interruptions. It is becoming clear that, without reliable solutions for fault current limitation, the connection of new energy sources will become costly and be postponed.

Because the issue of excessive fault currents is so widespread, a reliable solution for fault current management is required. When multiple connections of distributed generation are made on the distribution network of a given substation located in dense urban or industrial areas, it becomes necessary to install fault current interrupters at the generation sources. This eliminates the fault current contribution from the distributed generation source into the distribution network.

To address this potential problem, Western Power Distribution (WPD, now called National Grid) — one of the UK’s distribution network operators (DNOs) — launched the EDGE-FCLi innovation project. Funded by the Office of Gas and Electricity Markets (Ofgem’s) Network Innovation Allowance, the project kicked off in September 2018.

WPD selected GridON to develop and demonstrate a novel fault current-limiting interrupter (FCLi) based on power electronics that would have an immediate recovery capability and not require site presence or parts replacement following an interruption operation. The FCLi was built and successfully tested. It has been energized within a field trial in a live network, which will allow for its adoption. This device is aimed to be used by distributed generation customers to accelerate their connection to DNO networks.

Fault Current-Limiting Interrupter

GridON’s FCLi uses a proprietary power circuit based on insulated-gate bipolar transistors (IGBTs) as electronic switches that conduct the generators’ current to the network in normal conditions. An ultra-fast fault detection mechanism enables rapid interruption of the fault current, typically within less than half a millisecond. The FCLi is connected to the operator’s network management system, which enables remote control of the device.

After an interruption operation, the device is immediately ready to resume normal current conduction by remote command with no need for on-site service or parts replacement. The FCLi is easy to install and operate, and it requires minimal maintenance. It also is equipped with signal logging capabilities that enable analysis of its behavior by simple data retrieval from its local storage device. The design of the FCLi was accompanied by a distribution network connection study.

Testing The Design

The development stage of the FCLi culminated with the execution of a comprehensive suite of tests reviewed and approved by WPD. Initially, an enclosure was manufactured for destructive internal arc classification tests. The tests were conducted at KEMA Labs and carried out in accordance with IEC 62271-200. Following these tests, a fully functional FCLi unit was manufactured and factory acceptance tests (FAT) were performed.

The tests included dielectric tests, such as a power-frequency withstand test at 28 kV, and lightning impulse tests at 95 kV. Then the unit was subject to a series of functional tests that demonstrated all its operational modes and, finally, went through full-rated current tests, including temperature rise tests. The FCLi is designed with self-diagnostic capabilities, which also were tested during FAT. Following successful FAT, the FCLi was tested at KEMA Labs for short circuits.

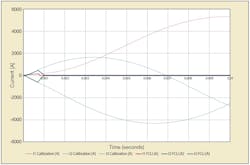

The unit was subjected to faults ranging from a few hundred amperes up to 25 kA rms, demonstrating its capability to interrupt these currents well before the first current peak. This is a necessary feature for any fault current limiter, as its main purpose is to ensure no equipment on the network is exposed to a fault current beyond its ratings.

Furthermore, the FCLi is designed with power-circuit redundancy to enable current interruption even in the unlikely event of some components failing. Some of the short-circuit tests were aimed to prove the FCLi could indeed interrupt fault current when parts were simulated to fail. The device passed these tests successfully. All the tests were witnessed by WPD representatives and, subsequently, the FCLi was approved for installation.

Installation And Energization

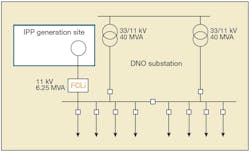

Following the successful testing at KEMA Labs, the FCLi was installed in WPD’s 33/11-kV primary substation on the University of Warwick campus, where high current levels are generated by three combined heat and power (CHP) generators with a total power of 4.2 MW. The FCLi is connected to an extension panel added to the 11-kV switchboard for this installation.

WPD supervised the installation, connection, commissioning and energization of the FCLi, which had an initial operational run period. Following minor adjustments, the system was put into service in late 2021. The FCLi is connected in series between three 1.4-MW synchronous CHP generators and the WPD substation’s 11-kV bus bars, supplied by two 40-MVA, 33/11-kV transformers running in parallel.

FCLi Features

The FCLi is equipped with a high-resolution data logger that enables recording both analog and digital signals when events occur, such as fault current interruption and any abnormal device behavior. It also includes an auto-start feature to ensure it is ready for operation within a matter of seconds. The operator remotely controls the FCLi’s operation through a simple interface and monitors its condition through telecontrol. The FCLi includes extensive self-diagnostic features, providing clear visibility of any potential problems that may develop within the device.

The FCLi can instantly recover from fault current limitation to normal current conduction, by a remote command from the operator. This means, following fault clearance, the generator that is protected by the FCLi can be resynchronized to the distribution network. It can immediately resume normal power generation, so there is minimal impact to the generation customer.

The FCLi installed in the UoW primary substation is under the full control of WPD’s network management system, in common with all other devices connected to the distribution network. The FCLi is straightforward to maintain, as maintenance only includes periodic inspections and air-filter replacements.

With the 5-MW, 11-kV FCLi device now in operation, GridON also has developed a 1.5-MW, 400-V FCLi and is working on a power-electronics-based fault current limiter for networks up to 38 kV, supporting power ratings up to 150 MVA. This device will be targeted for DNO substations and large-scale generation.

Equipment Longevity

With the ever-increasing demand for distributed generation connections into distribution networks, the issue of fault-level management requires solutions on the customer’s side. For these solutions to be effective, they must be able to recover immediately after network fault events and provide a rapid return on investment to the customer.

Power electronics-based interrupters provide both of these benefits and enable DNOs to maximize the longevity of their equipment, avoiding operational restrictions and equipment replacement that would otherwise be necessary.

Uri Garbi ([email protected]) has BSEE (cum laude) and MSEE degrees and has spent the last 28 years in senior research and development positions in the high-tech and power industries, leading engineering teams across multisite, multinational research and development projects. Garbi joined GridON in 2011 as vice president of research and development, leading the development of GridON’s products in utility substations and coordinating the utility customer, engineering, manufacturing and commissioning contractors and technical consultants.

For More Information

GridON | www.GridON.com

About the Author

Uri Garbi

Uri Garbi ([email protected]) has BSEE (cum laude) and MSEE degrees and has spent the last 28 years in senior research and development positions in the high-tech and power industries, leading engineering teams across multisite, multinational research and development projects. Garbi joined GridON in 2011 as vice president of research and development, leading the development of GridON’s products in utility substations and coordinating the utility customer, engineering, manufacturing and commissioning contractors and technical consultants.