Indian Utility Adds Self-Healing Capability

Tata Power Delhi Distribution Ltd. is a joint venture between Tata Power and the Government of National Capital Territory Delhi. The utility is responsible for delivering power to some 1.9 million customers across 510 sq km (197 sq mile) in the north and northwest areas of the Indian city of Delhi.The existing distribution network contains 56% underground cables, 24% bare overhead line conductors and 20% overhead aerial-bunched conductors. Currently, the peak load on this 11-kV distribution network — spanning 4349 circuit km (2702 circuit miles) — is more than 2 GW and increasing by 5% to 7% per annum.

The overhead line distribution network in the suburban area consists of bare conductors with multiple tee-offs from the main overhead line feeders.This network has been experiencing transient tripping and unplanned outages for a variety of different reasons, primarily because of vegetation growth near the overhead line conductors, bird faults and flying conductive foil papers contacting the main lines during storms.

These faults have an adverse impact on the system average interruption duration index (SAIDI) and system average interruption frequency index (SAIFI), especially when faults on the downstream tee-offs result in outages on the main over headline feeder.

Today’s businesses and day-to-day living are highly dependent on electronic equipment power systems; outages are no longer acceptable. Furthermore, the COVID-19 pandemic resulted in new ways of living and working, increasing the demand for a high-quality uninterruptible power supply. Since taking over the electricity business in 2002, Tata Power Delhi Distribution Ltd. (TPDDL) has been faced with the major challenges of improving network security and reliability. To address these challenges with its 11-kV distribution network, the utility launched a fault detection, isolation and restoration (FDIR) program to establish self-healing on critical feeders following an outage.

FDIR Program

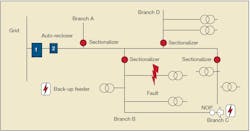

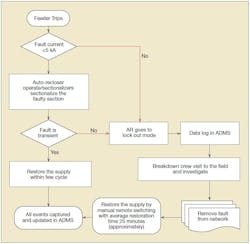

The FDIR program was established with a combination of overhead autoreclosers and sectionalizers, with the former installed on and offering protection to the main overhead line feeders and the sectionalizers installed on the tee-off overhead lines. The autoreclosers are designed as a combination circuit breaker and relay unit that offers protection and measuring functions, whereas the sectionalizer usually only operates when the overhead line is deenergized. Sectionalizers also have protection relays, which can identify downstream phase, earth and sensitive earth faults. The algorithm of the interruption counter records upstream operations after a downstream fault is detected, when the current drops to zero and there is no source-side voltage.

If the fault occurs in a tee-off section of overhead line, the sectionalizer isolates the fault and auto reclosers restore supplies to the remaining network. The autoreclosers operate when a fault occurs on a main line overhead feeder, restoring the transient faults; in this case, no sectionalizer will operate.

Operational Challenges

Auto-reclosers and sectionalizers are designed to be installed outdoors; therefore, the design must withstand variable harsh ambient conditions to deliver sustained performance. TPDDL’s 11-kV overhead line distribution network is subject to the following environmental conditions in the Delhi region:

The average summer temperatures are 40°C and 50°C (75.2° F to 93.2° F) while winter temperatures are as low as 0°C (32°F).

- Moderate to heavy rainfall during the monsoon season — exceeding some 700 mm (28 inches) of rain annually — can cause water logging and flooding. The humidity varies from 0% to 100%.

- Electronic cards inside the auto-reclosers’ controller installed near the industrial belt can become corrosive from the acidic fumes of the industrial plants.

- Finally, some locales in the region experience tampering and some residential neighborhoods are in proximity to the overhead line distribution network, which creates potential safety threats and hazards.

To combat these challenges, overhead line supports with a high-pollution protection of 31 mm/kV (1.22 inches/kV) are used and cabinets offering IP55 degree of protection, tamper-proof padlocks and brackets are installed. Use of International Electrotechnical Commission (IEC) 104 standard communication interfaces provides seamless transmission of auto-recloser linked events with nodal centers supervisory control and data acquisition (SCADA) connectivity. This enables real-time supportive action and quick intervention of mobile crews, when required.

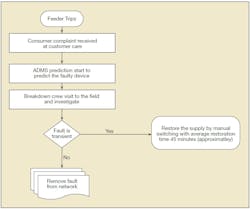

Distribution Automation

Distribution automation is an additional important feature that provides real-time monitoring of any faults and other important operational parameters. As auto-recloser operations following transient faults automatically restore supplies, breakdown crews only need to visit those units when a permanent fault occurs or to perform annual preventive maintenance. TPDDL’s auto-reclosers and sectionalizers are integrated with an advanced distribution management system (ADMS), so the number of operations (both transient and lockout), fault intensity, load current, voltage and high current lockout events can be monitored.

Connected by a 4G cellular network, the field devices are secure and can exchange data with the distribution network control center. This provides engineers in the control center with the option to operate the auto-reclosers’ on/off feature and enable/disable the auto-reclosing feature on the circuit breaker, in accordance with TPDDL’s disaster management plan.

The number of transient operations and lockout operations (that is, permanent faults) in the distribution network are shared with the maintenance team daily (through automatic mail from the Oracle server, integrated with the ADMS system), so they can manage and execute the necessary action. For the distribution feeders with the highest number of recorded operations, special maintenance arrangements are made to restore the security of the network. Similarly, for the auto-reclosers with the highest number of operations noted in the ADMS operational reports, preventive maintenance is undertaken as a high priority.

Program Results

To date, TPDDL has installed 398 fully FDIR capable auto-reclosers and sectionalizers, supplied by different manufacturers, on critical feeders to establish rapid self-healing of the suburban distribution network to enhance the reliability. The results of installing the combination auto-reclosers and sectionalizers are encouraging. For example, in the financial year 2021-2022, 1169 operations out of 1599 were successfully confirmed to be transient faults in nature. These numbers confirm only 430 auto-recloser operations resulted in lockout mode, indicating the faults either were permanent or a result of excessive fault current. Overall, the auto-recloser and sectionalizer combination has helped the utility to improve its SAIFI and SAIDI on the overhead line distribution network.

The entire distribution network TPDDL inherited from the Delhi Vidyut Board in 2002 was in an extremely dilapidated condition, with frequent blackouts and brownouts as well as all-time-high reliability indices of 110 hours per annum for SAIDI and 55 interruptions per annum for SAIFI. As a result of capital investment and well-planned efforts, these indices are now 0.98 hours per annum for SAIDI and 1.75 interruptions per annum for SAIFI, and these indices continue to improve.

Shrinjoy Bagchi ([email protected]) has an M.Tech degree in energy and environmental management from the Indian Institute of Technology, Delhi, and is the deputy general manager in the protection, testing and automation division of Tata Power Delhi Distribution Ltd. He currently leads the protection and automation group in the company. Bagchi has 16 years of experience in power system protection, automation, substation commissioning, network planning, underground cable fault location and network maintenance.

H.C. Sharma ([email protected]) has a B.Tech degree in electrical engineering from the Aligarh Muslim University, where he was awarded the Gold Medalist honor, and earned a post-graduate certification in business management from XLRI, Jamshedpur. He is the chief of business development, contracts, stores and technical services at Tata Power Delhi Distribution Ltd. Sharma heads the function that includes business development, stores, power system control, quality assurance and technical services. He has worked on many prestigious projects and been instrumental in the development of plant engineering and quality assurance systems for the utility. He also has also worked on various verticals of projects that include design, engineering, quality assurance, and procurement and execution.

About the Author

Shrinjoy Bagchi

Shrinjoy Bagchi ([email protected]) has an M.Tech degree in energy and environmental management from the Indian Institute of Technology, Delhi, and is the deputy general manager in the protection, testing and automation division of Tata Power Delhi Distribution Ltd. He currently leads the protection and automation group in the company. Bagchi has 16 years of experience in power system protection, automation, substation commissioning, network planning, underground cable fault location and network maintenance.

H.C. Sharma

H.C. Sharma ([email protected]) has a B.Tech degree in electrical engineering from the Aligarh Muslim University, where he was awarded the Gold Medalist honor, and earned a post-graduate certification in business management from XLRI, Jamshedpur. He is the chief of business development, contracts, stores and technical services at Tata Power Delhi Distribution Ltd. Sharma heads the function that includes business development, stores, power system control, quality assurance and technical services. He has worked on many prestigious projects and been instrumental in the development of plant engineering and quality assurance systems for the utility. He also has also worked on various verticals of projects that include design, engineering, quality assurance, and procurement and execution.