UK Utility Transforms the Capture and Use of Inspection Data

Part of the SSE Group, Scottish and Southern Electricity Networks Transmission owns and maintains the 400-kV, 275-kV and 132-kV transmission systems across the majority of Scotland. In 2019, the utility reviewed its digital strategy, outlining its commitment to safety, innovation and the best environmental practices — particularly those that apply to the routine operation and maintenance of its transmission system assets, such as overhead lines and substations in northern Scotland. The utility’s asset base includes around 11,500 transmission line towers and 158 substations and switching stations.

Transmission line faults create disturbances that can have a significant impact on the system, reducing overall stability and security as well as resulting in the loss of renewable energy generation, as is often the case with modern networks. In extreme cases, it can even result in the loss of widespread customer supplies. For this reason, Scottish and Southern Electricity Networks (SSEN) Transmission works hard to ensure its inspection and maintenance programs are robust. Traditionally, this included field staff climbing transmission towers to carry out routine inspections, intervening to replace worn and damaged fittings as they found them. However, this required circuit outages and had the inherent risks associated with working at heights.

Multilevel Data

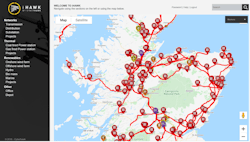

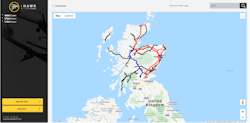

Recognizing the benefits of effective data management, SSEN Transmission now accesses terabytes of data captured from drone inspections on Cyberhawk’s cloud-based internet of things (IoT) visualization platform, iHawk. This enables the utility to actively manage assets throughout their life cycle and accurately make informed future capital investments, driving whole-life value.

iHawk offers operational, project and asset teams unprecedented access to multilevel data, giving them a more comprehensive understanding of the network, exposing integrity risks and revealing opportunities for improvement. This innovative approach to data management is key to managing network assets and central to how SSEN Transmission’s operational team manages inspections, maintenance, safety and compliance.

Drone Inspections

By carrying out drone inspections as business as usual and ensuring the data is efficiently processed and accessed on iHawk, SSEN Transmission’s highly skilled operational teams can identify issues early and focus interventions on the highest priority items, before they fail.

The condition of towers and insulator fittings can deteriorate over time, leading to potentially catastrophic incidents. Therefore, the first priority is to provide a safe and secure transmission network. After all, the risk is too high to adopt piecemeal or percentage-based inspections. To overcome this, Cyberhawk continues to support SSEN Transmission by conducting regular drone-based inspections, which are agile, use time effectively and provide a safer alternative to the in-person method. Put simply: The operational staff and their time are too precious. Drone surveys provide the opportunity to get the most from this team while reducing risk and improving the performance of the network in the most efficient manner.

For example, in 2020, Cyberhawk’s visual inspection data identified a missing split pin on a tower fitting. As a result, an outage was planned and a repair carried out the following weekend. In this case, the drone data on iHawk likely prevented a circuit failure and the loss of a key transmission circuit. By keeping its transmission lines in top condition, SSEN Transmission can retain a high level of network reliability at the lowest cost possible, ensuring delivery of the best value to the customer.

Furthermore, SSEN Transmission also has worked with Cyberhawk on the iSim application within iHawk, enabling the utility to apply the same rigor in managing its substation assets. As a result, inspection and maintenance data now are entered at the point of work, ensuring accuracy and the most up-to-date information is available for the maintenance teams.

Data Collection

Cyberhawk’s data management solution also provided the system for compliance. As part of a compliance audit, iHawk ensures the SSEN Transmission data systems satisfy the statutory obligations of the electricity safety, quality and continuity (ESQC) regulations as the main holding of the data interrogated. ESQC regulations (2002) dictate that electricity distribution and transmission utilities must inspect and maintain accurate records of their assets. Without these records, SSEN Transmission would not be able to comply.

iHawk put the data at SSEN Transmission’s fingertips, allowing teams to rapidly access historic information in one centralized place, providing ease of navigation and categorization. The utility can pinpoint key information, such as general-condition data, number of defects reported during any given time period in any given area or circuit, plus evidence to confirm remedial work orders have been completed.

iHawk functionality enables efficient reporting of defects identified during substation and overhead line inspections, enabling team members to tag defect notices to any given asset or location. The ability to include pictorial evidence and user commentary before autonomously passing an inspection over to maintenance managers for approval, scheduling and reporting enables quick reaction to any defects identified.

Environmental Impact

SSEN Transmission recognizes the digitalization of its systems and processes — underpinned by high-quality, accessible data — reinforces its commitment to deliver a network for net zero. Sulphur hexafluoride (SF6) has been used extensively as an insulation medium in high-voltage equipment for more than 60 years, but it is now recognized as one of the most potent greenhouse gases. Although the industry is beginning to develop alternatives — environmentally friendlier insulation and interrupting gases — the amount of SF6 is so vast it will be on the network for years to come. To mitigate the impact of this legacy and maximize network availability and performance, SSEN Transmission works tirelessly to reduce the leakage of SF6 gas from its assets.

SSEN Transmission is now benefitting from Cyberhawk’s decades of oil and gas industry experience. The company recently introduced a new pressure-monitoring system that enables SSEN Transmission’s plant maintenance teams to remotely monitor the SF6 gas chambers and zones within the utility’s assets.

An IoT sensor monitors for any leaks of the colourless, odourless synthetic gas. As soon as the system identifies a reading — regardless of the volume and how minor the leak — the operations team is alerted to take remedial action and repair the leak immediately, to limit gas from escaping into the environment. This not only enables the utility to manage SF6 leaks proactively, but it also improves network performance, allowing plant outages for gas top-ups to be coordinated in a wider program and reducing the need for immediate, forced action.

Impact of Covid-19

When the impact of Covid-19 on the UK population became clear at the start of 2020, many businesses faced disruption of their day-to-day operations. Therefore, maintaining a secure and reliable supply of electrical energy was more essential, creating more pressure than ever before. The pressure was on utilities and their employees to continue to deliver this essential service despite the imposed restrictions.

SSEN Transmission has an unwavering commitment to keeping people safe, reiterated by its safety message: “If it’s not safe, we don’t do it.” In March 2020, SSEN Transmission faced the challenge of ensuring critical inspections and maintenance activities continued while allowing staff to comply with social distancing. Using iHawk tablets meant there was no reliance on paper-based systems, so it was possible to minimize face-to-face contact between the maintenance teams and engineering staff.

Stuart Knight (email address) has 15 years of industry experience with Scottish and Southern Electricity Networks (SSEN), starting as an apprentice and progressing, via protection and control engineering, to the position of head of operations. With wide experience in operations, maintenance and large capital projects, Knight has played a significant role in the growth of the northern Scotland transmission network over the past decade, with highlights such as commissioning SSEN’s first 400-kV site, first IEC 61850 installation and first high-voltage direct-current link, all while supporting the day- to-day operations of the T&D business.

About the Author

Stuart Knight

Stuart Knight has 15 years of industry experience with Scottish and Southern Electricity Networks (SSEN), starting as an apprentice and progressing, via protection and control engineering, to the position of head of operations. With wide experience in operations, maintenance and large capital projects, Knight has played a significant role in the growth of the northern Scotland transmission network over the past decade, with highlights such as commissioning SSEN’s first 400-kV site, first IEC 61850 installation and first high-voltage direct-current link, all while supporting the day- to-day operations of the T&D business.