Recent Customer Engagement Effort Shows Everything Old is New Again

A recent announcement I read about AEP Ohio and DNV GL receiving an energy efficiency related award had a certain ring to it. It reminded me of something I’d read years ago about how U.S. electric utilities were the largest retailers of refrigerators in the early 1920s.

The common thread between the “new news” and my research-based “old news,” equipment-wise, involves advancements in refrigeration.

Researching further, I learned additional details about how customer research and product ROI and R&D work, which U.S. electric utilities did in the 1920s, played a key role in how new and more efficient appliances were originally brought to market.

Wow. Now, instead of 25%, U.S. utilities represent 3% to 5% of the GDP, and probably less than half that portion, when it comes to new investment. Does this relatively lower investment give you pause and lower your level of optimism about potential positive impacts of our industry’s new customer engagement efforts?

How much of our industry’s early successes depended upon the sheer drive associated with growth and with the clout utilities wielded when marketing the advantages of new technologies, even if a price premium was involved?

First, let me tell you more about what I learned from my look back in time, before I provide details on the recent announcement by AEP Ohio about a venerable award it received from the Association for Energy Services Professionals (AESP), which triggered my interest and prompted to take this look 95 years back in our industry’s history.

In the 1920s, utility marketing efforts included getting appliance manufacturers to lower prices based on the promise (which utilities fulfilled) of higher levels of residential appliance sales. In addition, utilities spearheaded efforts to demonstrate the service reliability, “soft” benefits, and ROI of new electric appliances to their customers directly, within each utility’s local service territory. Utilities also formed committees and processes to systematically report needed improvements back to manufacturers.

For Brooklyn Edison, a 1922 article in Electrical World had a telling title and subtitle: “Household Electric Refrigeration: Investigation Shows Great Possibilities for Load Building—Better Servicing Facilities Must be Provided—Comparison of Costs,”, by T.I. Jones, General Sales Agent.

The article reviewed results of a survey Brooklyn Edison conducted, of 115 homes using electric refrigerators in the utility’s service territory. The average time in use for these 115 electric refrigerators was 19 months, and 95 out of the 115 respondents said their refrigerator’s operation was “generally satisfactory.”

In the 1920s, utilities had to collaborate with manufacturers to ensure positive improvements in the ROI of an electric refrigerator versus the competing incumbent ice-based technology. And utilities also had to incentivize customers and also had to perform customer research and push for improvements in service levels for the new electric refrigerators for residential programs to grow.

Brooklyn Edison analyzed with great rigor the difficult economic hurdle electric refrigerators faced versus the incumbent technology. (A note to Gen X’ers and younger folks: Those of us who, in our youth, overlapped with people who talked about what life was like in the 1920s or 30s, would know that the incumbent technology before refrigerators was a device called an “ice box” and that the large blocks of ice were delivered by horse-drawn or motorized vehicles, as a service, directly to the home.)

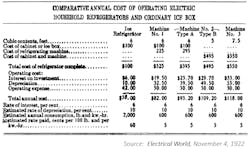

A sample of one of the article’s ROI calculations is shown. The sample table below refers to an ice-box as an “Ice Refrigerator,” while referring to the electric refrigerators as “Machine No. 1, 2, and 3.”

Jones concluded his article with recommendations that utilities "encourage the sale of the electric household refrigerator as at present developed, it being understood that with this encouragement the manufacturers guarantee proper servicing conditions.”

Jones also suggested that "a committee from this Association or an individual investigator be appointed to continue the investigation of this subject, reporting from time to time the development of the appliance and calling to the attention of the apparatus manufacturers any general criticisms on their machine and service.”

Interestingly, an article by another utility sales person showed the power utilities wielded, arguing that maintaining a price premium might not be a bad idea, but also showed how they wanted to use their marketing advantage of being closer to the customer than the equipment manufacturers, to grow the residential electric appliance market.

The article was titled “A Sales Force for a Scattered Territory,” by W.E. Prosser, Sales Department, Adirondack Power & Light Corporation, Amsterdam, NY.

Prosser argued that the electric utility industry companies had “little or no reason to sell merchandise at cut prices. On the other hand, it has not been found good policy for companies to retire absolutely from the merchandising business. The electric power company enjoys a certain advantage over other merchants in that almost every one of its customers must come in contact with it at least once a month, and this offers the central station an excellent opportunity to provide an additional service to its customers in supplying them with standard appliances and at the same time earn a profit from their sale.

“The most serious problem that confronts the company with regard to merchandising is how best to organize and conduct a sales department so that the company’s territory will be adequately covered and at the same time the investment in stock and the selling expenses will be kept down and a profit can be made. This company operates 13 stores in the Upper Hudson and Mohawk Valleys, where we provide electrical service. In four of these towns we also operate gas plants, and for this reason we sell both electric and gas appliances. In all of these towns we have salesmen who canvass their districts for certain appliances, and where the town is large enough to support a specialist we have men who specialize on certain articles and appliances. However, we find it necessary and advisable to use as much as possible the cooperation of manufacturers on the larger equipment such as electric refrigerators…”.

Similarly, in much the same way that these vintage 1920 projects depended upon marketing and sales efforts and organized collaborations with manufacturers, AEP Ohio, along with DNV GL, helped to facilitate adoption of a new energy-efficient technology for ultra-low cooling (ULC) refrigerators.

As a result of the joint efforts by AEP Ohio and DNV GL effort, both companies received the 2018 Energy Award for Outstanding Achievement in Emerging Tools and Technologies by the Association of Energy Service Professions (AESP). Both companies were recognized for their efforts to secure a new ultra-low temperature (ULT) freezer technology’s ENERGY STAR certification and to design a customer friendly incentive structure.

The potential energy savings sited in AEP’s announcement if this technology were adopted widely is a big figure (2,000 GWH), as it represents a significant fraction of a percent of the total 2016 U.S. electric energy consumption (3,762,462 GWH).The incentive AEP Ohio implemented was administered by partner DNV GL to encourage the adoption of the technology, and enabled qualified customers to earn $20 per cubic foot capacity when installing a Stirling UTL freezer.

ULT freezers are used by hospitals, universities and laboratories to store sensitive biological samples. The new technology reduces electrical usage by up to 75 percent while maintaining equivalent temperatures.

“The opportunity to create a new market for energy efficient technologies and products is one that AEP Ohio consistently seeks out,” said Andrew McCabe, commercial programs manager. “Helping Stirling Ultracold achieve ENERGY STAR certification and bring this technology to a market where there was no energy efficient alternative was a way to provide significant energy savings to the ultra-cold segment.”

AEP Ohio reached out to the EPA and Stirling Ultracold to accelerate the ULT freezer ENERGY STAR certification process. Together with DNV GL, the organizations reviewed third-party data to verify savings calculations and design the incentive structure.

With an available U.S. market of up to 800,000 units, this new technology will create significant energy savings. The product has the potential to reduce consumption by over 2,000 GWh nationwide.

“This unique partnership between a utility and manufacturer is a blueprint that other utilities can follow,” said McCabe. “Typically, utilities wait for the manufacturer to approach them with certified innovative products but, in this case, AEP Ohio initiated the discussion to drive the industry recognized energy star certification.”

About the Author

Peter Arvan Manos

Utility Industry Analyst

Peter Manos is Director of Research for Electric Power & Smart Grid, on the Energy Sector team at ARC. He analyzes the latest trends across People, Process, and Technology to uncover business and digital transformation best practices for electric, gas, and water utilities. He can be reached at [email protected]