Simulation Training Closes the Skills Gap

The executive team at ElectriCom has worked on enhancing the company’s operator training program, making changes that bolstered one-on-one coaching, shortened learning curves, kept productivity high, and improved safety.

Based in Paoli, Indiana, ElectriCom is a full-service utility solutions and maintenance company that works on projects of all sizes and levels of complexity — from connecting communities to broadband to reducing service outages. The company employs almost 500 people, with roughly 300 of those employees working in an operations capacity and nearly 200 operating construction equipment such as excavators, digger derricks, skid steers and backhoes.

Enhancing training while shortening learning curves isn’t an easy feat — but it is one that is becoming increasingly important as companies navigate the labor shortage. Fortunately, the company was able to do so, all while keeping productivity high and enhancing safety. It was even able to upgrade its recruitment strategy and lower its training costs, too.

How was ElectriCom able to achieve these outcomes? The answer lies in simulation training. Over the last few decades, advancements in computer processing and simulation technology have made simulations incredibly detailed and realistic.

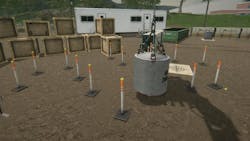

Some simulation training solutions are even able to accurately recreate how cables swing in the wind, how equipment behaves as it tips, and how dirt clumps, spreads and moves. CM Labs engineers each of these sensations with such precision that veteran operators have reported that they can operate a simulated machine relying on nothing more than the sounds and vibrations from the controls and seat.

For early adopters, simulation training is an addition that is proving to be a game changer for the utility industry. While ElectriCom’s adoption of simulation training began as an effort to enhance its training program for excavator, digger derrick, and other heavy equipment, it quickly became a cornerstone of its workforce development strategy.

Training Efficiency and Effectiveness

Today, when a new operator starts their training at ElectriCom, they begin with a classroom Q&A session and written test. After passing the test, they move on to a simulator for several hours of initial training. The operator becomes familiar with the controls and how the machine behaves. They receive feedback from their instructor — who has access to detailed metrics on their performance in real time — then proceed to real equipment to finish the last of their training.

“It’s a standardized approach that means every operator gets the same instruction,” said Steve Putt, the VP of Human Resources at ElectriCom. “They’re evaluated with the same objective metrics, they complete the same exercises, and they all get individualized feedback and instruction to correct mistakes.”

Traditional on-the-job training methods can sometimes lack standardization and rely heavily on the transfer of tribal knowledge. Simulators, by contrast, offer a structured learning environment. This means that every operator is trained and tested to the same, measurable standard — while any operator struggling with lessons can receive extra guidance and feedback to address mistakes. It’s also an approach that makes it easier to train many operators to proficiency quickly.

"Training solely on real equipment made coaching challenging," explained Kyle Lautner, a Safety Manager at ElectriCom. "With the simulator, I can physically guide the trainee’s hands, provide direct instruction, and engage in real-time discussions. It’s a far more effective approach, which is why we’re noticing significantly shorter learning curves."

With simulation, operators can practice exercises over and over, gaining the concentrated seat time they need to rapidly develop their skills. The latest generation of simulation training tools also offers an incredible amount of training management, data reporting, and student monitoring features that allow one instructor to train more students simultaneously.

“Simulation technology has evolved,” said David Mailhot, the Director of Product Management at CM Labs. “Our Intellia Instructor tool, for example, allows trainers to inject faults into exercises, monitor multiple students at once, gain detailed insights on performance, craft custom learning paths, and export training data for further analysis and safekeeping. This helps trainers teach more students at once, as well as streamline administrative tasks.”

As a result, training new operators, or cross-training and upskilling experienced ones, becomes much faster.

Enhancing Safety, Reducing Risk

Exporting training data for record-keeping helps with meeting compliance and regulatory requirements, as well as improving workforce development tracking and performance tracking over time. It also provides proof of training — which can be especially useful in the event of a safety incident. Using simulators for training also benefits safety, reducing the likelihood of an incident occurring in the first place.

“One of the most significant advantages of simulation training is its impact on safety,” said CM Labs’ Mailhot. “If a student makes a mistake in a simulation, they can learn from it. But if they make that same mistake on real equipment, it could result in a serious injury or damage.”

Operating heavy machinery in a live environment carries inherent risks, particularly for inexperienced workers. According to OSHA, nearly 25% of all construction-related fatalities involve heavy equipment operations. Simulators allow trainees to familiarize themselves with equipment controls, learn best practices, and make mistakes in a zero-risk environment. As a result, by the time they transition to real equipment, they already have a solid understanding of how the machine works and how to operate it safely.

Another key benefit of simulation training is its ability to train workers for emergency scenarios, such as equipment malfunctions, adverse weather conditions, distraction, and hazardous jobsite environments. These scenarios would be difficult, costly and dangerous to replicate in a real-world setting, but can be safely practiced on a simulator.

“There are certain scenarios you wouldn’t want to try on real equipment,” Mailhot said. “It would simply be too dangerous. But having that experience can make a huge difference in the field when an operator does encounter something like a machine malfunction. Simulation training can help an operator gain that experience, which can be life-saving.”

Cost Savings

According to Dodge Construction Network Data & Analytics, companies that adopt simulation-based training see up to a 30 percent reduction in training costs compared to traditional methods. There are a few reasons why.

When training operators on real equipment, fuel costs, equipment maintenance, and lost productivity from machines taken off worksites all contribute to high training expenses. Simulation training cuts these costs down by allowing operators to practice on a simulator instead. As a result, equipment can stay in the field earning money, while less fuel is burned during training.

“With simulation training, there are no fuel expenses and there is no equipment damage,” said ElectriCom’s Putt. “New operators can be tough on machinery. Simulators protect fleets from that added wear and tear, which helps keep them operational for longer. Meanwhile, the actual equipment stays in the field where it generates revenue, ensuring no loss of income."

These benefits can have a significant impact on a company’s bottom line. “We’ve had clients who were able to reduce their training costs by more than 50%,” said CM Labs’ Mailhot. “Those lower training costs make it a lot easier for companies to bring in new talent with no prior experience. It’s an advantage that can make a real difference in today’s competitive landscape.”

A Pipeline of Skilled Operators

Simulators are most often used to train operators, but a few innovative organizations have started to use them in other ways, too. Some have found that simulators are especially good at generating excitement among younger generations at career fairs, job fairs and other recruitment events. Screens and controls are familiar to many young people, who may not have had exposure to cranes and other lifting equipment. Simulators provide an opportunity for young people to see these careers in a new light and envision themselves working as operators.

As a recruitment tool, simulators allow companies to engage potential candidates through interactive and immersive experiences, demonstrating the technological advancements within the industry. Unlike traditional job presentations, simulators provide a hands-on experience, making it easier to capture the interest of someone who may not have previously considered a career in utility construction. As a result, recruiters using simulators often see a spike in interest.

But simulators also support recruitment in other ways. At ElectriCom, they’re used to evaluate new talent. Every time a new employee joins the ElectriCom team, they spend some time on the simulator, completing basic exercises to see if they have a natural aptitude and interest in equipment operation.

“We evaluate factors like hand-eye coordination,” said ElectriCom’s Putt. “For example, someone might be hired as an overhead power lineman, but after seeing their performance on the simulator during orientation, we realize they could quickly develop the skills needed to become a proficient equipment operator.”

Simulators shine a light on talent within a workforce. The objective metrics they provide give recruiters a data-driven view on performance.

Some CM Labs clients use simulators when hiring experienced operators, which Mailhot says helps detect the best operators. “Sometimes candidates might lie about their experience. By testing their skills on a simulator, hiring managers can determine who really has the skills they claim to,” he said.

Gaining a Competitive Edge

As the industry continues to face labor shortages and rising training costs, simulation technology stands out as a solution that addresses multiple challenges simultaneously. “The technology has come a long way,” said Mailhot. “Our simulations have more than 25 years of research powering them. It’s technology that has been trusted by NASA and the European Space Agency (ESA). These are highly realistic, detailed simulations.”

For early adopters in the utility industry, it’s proven to be a boon.

“We really trust the quality of our simulators and what our trainers can achieve with them,” said ElectriCom’s Lautner. "There have been times when a real machine wasn’t accessible for training, or when weather conditions made outdoor practice impractical. In those situations, we simply conducted the full training session using the simulator."

By leveraging cutting-edge training tools, utility companies can build a workforce that is skilled, safe, and prepared for the demands of the job quickly and effectively.

About the Author

Shane Matthews

Shane Matthews is the Director of Training and Development at ElectriCom, a utility infrastructure company specializing in electric, telecommunications/fiber optic, and storm response. Currently, Matthews oversees ElectriCom’s LMS platform, new employee orientation, Leadership Development programs, and DOL Apprenticeship programs. Matthews is the Chair of the PCCA (Power and Communication Contractors Association) Education Committee, as well as the Chair of WIA’s (Wireless Infrastructure Association) TIRAP Advisory Committee.

Devon Van de Kletersteeg

Devon Van de Kletersteeg is a Product Growth Manager at CM Labs, the leading developer of simulation-based training solutions for the utilities, construction, and ports industries. Van de Kletersteeg leverages his engineering background to drive market expansion and product alignment. He focuses on addressing real-world training needs with simulation technology, ensuring CM Labs’ solutions continue to evolve and drive measurable results across industries.