Transmission System Substation Refurbishment

Increasing dependence on electrical energy requires a secure and reliable transmission system. To meet these demanding challenges and to achieve renewable energy goals, the Republic of Ireland has focused intently over the past 15 years on investing in its transmission system, including several major substation refurbishment and replacement projects.

The Irish transmission system consists of four 400-kV substations, 45 220-kV substations and approximately 250 110-kV substations. A large percentage of the transmission system in Ireland was constructed in the 30-year period between 1960 and 1990. In the early 2000s, feasibility studies were conducted to identify the refurbishment requirements for several key bulk supply point (BSP) substations. These studies targeted equipment that needed to be replaced as a result of age, deterioration and inadequate rating.

A refurbishment program was created to determine the upgrade requirements for each of these substations to meet future demands. The general approach to this program was to consider one of two options:

• Option 1 was a partial approach to upgrading the substation equipment. With this option, only the plant and the control and protection equipment that required either immediate replacement or increased ratings would be replaced during the upgrade.

• Option 2 was a complete substation overhaul. With this option, the substation would be replaced in its entirety with a modern indoor gas-insulated switchgear (GIS) substation that has the possibility for future expansion.

Refurbishment Considerations

To determine which refurbishment approach to take, the following factors were considered during the project development phase:

• Requirement for increased ratings and additional feeders in the existing substations

• Compatibility of new equipment with the existing plant installed

• Space constraints within existing substation boundaries

• Operational and outage constraints

• Consideration of the cost and program.

The majority of the substations studied were proposed to be refurbished using the partial upgrade approach (option 1). However, because several of these substations required major refurbishment, the decision was made to overhaul the substation completely (option 2) by building a new GIS substation to meet all current and future requirements within the confines of the existing site boundaries.

Partial Upgrade Approach

The 220-kV Cashla and Flagford substations are situated in western Ireland, close to the main population centers. Both substations are system critical to ensure the security of supply for the area. Feasibility studies identified a need for improved reliability of the protection equipment to increase the availability of each substation.

The studies concluded that the majority of the substation switchgear should be retained in service because it was adequately rated and in a good state of repair. The locations of both substations are quite rural, and there was sufficient space on both sites to meet the existing requirements as well as to facilitate any future extensions to the busbars using the existing air-insulated switchgear (AIS) technology.

The project scope comprised the following works:

•Replace all electromechanical protection with duplicate modern numerical protection and the inadequately rated instrument transformers.

•Uprate line bay conductors to match the rating of the incoming overhead lines

•Upgrade the direct-current battery systems to provide redundancy in the protection design.

•Complete all the required civil works for the new control and protection cabling, in addition to constructing new bases for the replacement instrument transformers.

Significant work was required at the existing substation to accommodate the new protection schemes and instrument transformers. Design challenges included combining new feeders into existing common station synchronizing, position indication, remote control and interlocking schemes. All of these were designed and installed in the 1970s and had to remain in service for the duration of the protection upgrade work. The use of modern numerical protection meant all the existing signaling and telecommunications systems had to be upgraded.

Outages of seven-week durations were required to facilitate the upgrades on each of the critical circuits. In the 220-kV Cashla substation, there were three 110-kV feeders supplying the main city in western Ireland. As these feeders are system critical, a seven-week outage would not be workable. To overcome this problem, a temporary busbar was erected beneath all three of the overhead lines. The busbar was connected to a mobile bay, which was connected to the 110-kV busbar. This installation ensured all three feeders could be diverted, in turn, to the mobile bay and required only short outages.

The protection equipment in both the 220-kV Cashla and Flagford substations was upgraded successfully over the course of a three-year program. Bay conductors were uprated to meet the requirements for increased loads and new feeders were added as required. By improving the reliability of protection equipment, the partial upgrade approach has ensured the availability of both substations. However, the nature of the partial upgrade approach means quite a large proportion of the remaining substation switchgear has an increased risk of failure because of its age and will require replacement in the relatively near future.

Complete Substation Overhaul Approach

The 220-kV Carrickmines substation in South Dublin and the 220-kV Finglas substation in North Dublin are two of the main BSP substations for the Dublin region in Ireland. Feasibility studies identified a need to overhaul both substations completely. Several factors influenced the full replacement of these two BSP substations:

• Spare parts for the existing AIS, nearing the end of its useful life, were unavailable and the technology was no longer supported by the manufacturer.

• Increased feeding capacity was required. System studies indicated the need for additional 220-kV and 110-kV feeders and transformer capacity.

• Increased operational flexibility of busbars was required to enable different feeding arrangements.

• Insufficient space was available on the existing Carrickmines and Finglas substation sites, so substation extensions using the existing AIS station technology could not be accommodated.

The agreed-upon scope of the project was to replace the existing AIS equipment with GIS and install modern numerical protection equipment. GIS has all of the same components as AIS (such as busbar and disconnectors). However, as GIS is insulated by sulfur-hexafluoride gas (SF6) and fully enclosed, the footprint of a GIS substation is only a fraction of that of the equivalent AIS substation. GIS building locations were chosen to minimize high-voltage cable lengths and ensure adequate space would be available for any future expansion or redevelopment of each site.

In both cases, after planning permission had been obtained, considerable enabling works were required prior to the commencement of civil works. In the Carrickmines substation, the 220-kV busbar gantries had to be repositioned, while in the Finglas substation, several existing overhead line termination masts had to be relocated.

To ensure the security of supply was maintained during the transfer of existing circuits from the AIS substation to the GIS substation, it was decided the GIS and AIS substations would be linked. The link was made using a spare feeder bay in the AIS substation that was upgraded with new instrument transformers and protection, and connected to the new GIS substation by a high-voltage cable.

Difficulties included interfacing the modern control and protection schemes into the legacy schemes in the existing AIS substations and nonstandard designs were often required. In the case of the Finglas substation, two link bays were required as the load was so high.

In both the Carrickmines and Finglas substations, an automated substation control system (SCS) with individual bay control units was installed for the new GIS substations. Integrating the SCS with the existing AIS substation control system presented significant design challenges. For example, in the case of a 110/38-kV transformer — where the high-voltage side of the transformer is 110-kV GIS and the low-voltage side is 38-kV AIS — care was taken to ensure both sides of the transformer would be visible on the station control system (to avoid maloperations). This involved installing SCS hardware in the existing AIS bays and hardwiring the position indication of the switchgear and current/voltage measurements directly into the SCS.

Incorporating the existing plant into the SCS can be difficult because of the lack of position indication contacts, meaning design alterations and rewiring are often required. This is the type of issue that often only arises during the detailed design phase, so it is important to note some interface with the existing AIS station switchgear may be necessary either permanently or in the interim.

Impacts on Expected life

In both the Carrickmines and Finglas substations, the substation is fully refurbished and its useful life expectancy has been increased. Also, additional feeders have been added to make future expansion possible should it be required.

The partial upgrade approach projects were delivered successfully to both the Cashla and Flagford substations. All protection was upgraded to meet the latest standards; some additional feeder bays were added and bay ratings were increased to support an increase in load for both substations. However, since the completion of these projects in 2011, there has been a requirement for a number of other projects in both substations. For example, a type fault was discovered on the pantograph disconnectors on the 220-kV busbar that required their replacement.

Also, further overhead line and cable uprate projects have required the replacement of circuit breakers and busbar disconnectors on some feeder bays. This shows the partial upgrade approach is a short-term solution and will only reset the life cycle of the equipment that was replaced, not the complete substation.

The replacement of the AIS substation with a GIS substation at Finglas and Carrickmines has almost doubled the size of both substations, within the existing substation footprint, and the new GIS busbar arrangement provides for more flexible operational control of the busbars. This helps to decrease the risks involved in managing future outages. Additionally, these substations are now reset back to the start of their life cycle and should be relatively maintenance free for the foreseeable future. The majority of the AIS equipment recovered from the AIS substations has been retained to provide spare parts for maintenance or the replacement of faulty equipment elsewhere on the system; similarly, a selection of the off-line protection relays has been retained as strategic spares.

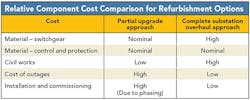

The partial upgrade approach projects were delivered at a much lower cost than the full substation GIS redevelopment approach. However, it is important to note, with this approach, the installation and commissioning costs are dependent on circuit outage availability. If the required outages are not phased correctly or become unavailable during the installation phase, these costs may rise significantly as a result of resources having to demobilize and remobilize to the site. Therefore, the cost of any future upgrades, as well as the cost implications of working under outage conditions, must be considered when planning for a partial upgrade approach project.

The full substation redevelopment approach has a much higher civil works and material cost compared to the partial upgrade approach, but the construction and commissioning are not outage dependent. The GIS substation can be built and almost fully commissioned before any circuit outage is required. Therefore, the installation and commissioning costs are lower than that of the partial upgrade approach. Replacement of several substations at the same time can include design savings by standardizing layouts and electrical designs. Also to be considered are the potential cost savings arising from less maintenance and increased plant availability.

Life-cycle management of substation equipment is an ever-present problem for modern utilities. To maximize the return on investment, it is necessary to develop and implement a strategy to renovate or replace existing transmission system assets. The two refurbishment approaches have been implemented successfully on numerous projects in the Republic of Ireland. Both approaches have their merits, but full consideration of all issues must be taken into account when planning the approach to take for any future substation refurbishments.

Barry Wall holds an honors degree in electrical engineering from the Dublin Institute of Technology. He joined ESB International (ESBI) in 2006 and has nine years of experience working on high-voltage substation projects for ESBI’s main clients — ESB and EirGrid — and has worked on overseas projects for Tanesco in Tanzania. Wall has primarily worked on delivering large gas-insulated switchgear substation projects and the renovation of air-insulated switchgear substations. In July 2015, Wall — a principal electrical engineer, a chartered engineer of the Institution of Engineers of Ireland and a member of CIGRE — joined AECOM Ireland.

Paul Duff has an honors degree in electrical engineering from the University College Dublin and a diploma in project management from Trinity College Dublin. Duff is a lead project engineer in ESBI’s high-voltage project delivery team, working on large-scale air-insulated switchgear and gas-insulated switchgear substation projects from 38 kV to 400 kV. He is a chartered engineer of the Institution of Engineers of Ireland and a member of CIGRE.