The Tennessee Valley Authority has transmission facilities in seven states in the mid-south region of the United States. The climate in general is mild with neither extreme heat nor cold; however, the Tennessee Valley is exposed to a wide range of natural events. The valley lies in the middle third of the U.S., which is prone to severe tornado activity. Parts of the valley also receive significant ice accumulations and severe thunderstorms on a regular basis in addition to isolated flood events and straight-line winds, all of which can disrupt the transmission system.

Tennessee Valley Authority (TVA) developed a resiliency matrix with 12 risk categories to serve as a single-point repository for documentation, an educational resource for new employees, and a backup source of information for use in emergency or drill situations (see “TVA Builds Resilience,” T&D World, April 2018). One of the 12 risk categories is “severe storms.” A few information categories from the resilience matrix have been summarized as examples of the depth to which TVA explored each risk category.

Assess

TVA has taken an active role in assessing storm damage to determine the best steps to prevent storm damage and harden the transmission system. The bulk transmission system has

a 500-kV backbone with a 161-kV underlay, and most of TVA’s customer delivery points are located on the 161-kV system. Based on TVA’s transmission assets, the relative im-portance of each system and consequences of an interruption to either one help to guide determinations made from these assessments.

The transmission field operations (TFO) group is tasked with physically inspecting out-of-service lines to determine the location of damaged structures and the extent of damage. The severity of the damage will dictate the resources and crews assigned to restore these facilities. This physical assessment also will become a factor in determining the restoration sequence, as the damage to some transmission lines will require more time to reenergize based on the breadth and depth of damage incurred. For expediency, helicopters often are used to fly the transmission line route and, most recently, drones also are being used.

To ensure the transmission system is adequately hardened and can recover quickly to full operability, TVA will continue to assess the current severe storm events to determine if modifications need to be made to any of its specific loading criteria, material needs or other resources.

Prevent/Harden

TVA has taken several steps to harden its transmission line assets. Like most of the transmission utility industry, it has migrated to steel pole structures in lieu of wood poles. Wood materials rot, warp, twist, creep and split over time, decreasing structural capacity. They also can be degraded by woodpecker holes, insect damage or other wildlife. Steel poles are lighter than wood and easier to transport because they can be assembled in sections. Steel poles also are more fire-resistant than wood poles. Additionally, galvanized steel poles are more durable and have a longer life span. TVA incorporates a steel ground sleeve for its direct-embedded steel-pole structures, which provide extra protection at the susceptible ground line where corrosion can be the biggest threat to pole longevity.

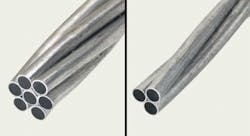

In the 1960s, TVA changed from galvanized high-strength steel ground wire for lightning protection on transmission structures to an Alumoweld wire design. Alumoweld wires consist of a thick coating of aluminum over a high-strength steel core. The first Alumoweld design that TVA used was a 3 No. 6 Alumoweld wire. The weak point of this wire is the stranding, which consists of three individual strands. If one strand is damaged, the wire loses one-third of its strength capacity, reducing its rated capacity to 6853 lb (3108 kg).

In response to this vulnerability, the standard shield wire design was revised to use a 7 No. 8 Alumoweld design. The 7 No. 8 Alumoweld wire has a rated breaking strength of 15,930 lb (7226 kg) and, although it is 42% heavier than the 3 No. 6 Alumoweld, it has a smaller diameter. If one of its seven strands breaks, the resulting wire capacity is reduced by only one-seventh to 13,654 lb (6193 kg). This modification to the standard overhead ground wire has helped TVA to eliminate many ice storm failures, because of the inherent redundancy of the seven-strand design and higher strength.

Operating Guides

In extreme events, rebuilding the system depends heavily on TVA’s standard programs and processes. At the highest level, the utility’s overall emergency management standard programs and processes (SPP) establishes the governance as well as oversight roles and responsibilities for mitigating, responding to and recovering from incidents that pose a threat to life, property, environment or systems disruption. The transmission emergency plan SPP specifically defines the roles and responsibilities of the transmission emergency team as they apply to the safe, efficient and orderly restoration of the TVA transmission system in the event of a major system interruption or natural disaster, and support for significant local power company (LPC) outages.

The transmission operations and power supply system alerts SPP describes the process for issuing or suspending system alerts. The purpose of these alerts is to inform TVA personnel of anticipated or immediate emergency conditions. This document guides timely and proactive implementation of system alerts. The power system restoration SPP ensures safe, efficient and orderly restoration of the TVA power system following a major interruption where the use of black-start resources is required to facilitate the restoration process. This procedure is applied in situations that include equipment failure, emergency-load curtailment, natural disaster or other operational problems that result in partial or total shutdown of the TVA transmission system.

In general, any operating guide put in place is unique and based on the specific assets damaged. In severe events, these can be developed on a case-by-case basis for use while recovery efforts are underway.

Recover/Restore

TVA is fortunate to have transmission and substation construction forces on staff as well as access to contracted construction forces. Construction crews in the TFO group have experience in building standard TVA transmission line structures in addition to knowledge of the dozens of structure types in the valley no longer used on new construction. Because they live in the Tennessee Valley, TVA construction crews know the regions, cities and towns and are familiar with the location of transmission lines. Being acquainted with TVA structure types and geographic areas provides the utility’s construction crews an advantage in determining the appropriate equipment needed to bring on-site for recovery and response efforts.

In a two-step endeavor, maintenance crews perform restorations for a multitude of issues that can be handled with more agile, smaller crews, while the transmission crews manage larger issues, such as stringing in new conductor, ground wire or fiber-optic cable. The maintenance crews have an intimate knowledge of structure assessment, location and access that evolves from daily interaction with transmission assets. Having unified efforts from both construction and maintenance ensures issues big and small are handled that fit the knowledge, skills and abilities of each crew. In the event storm damage is so widespread or devastating that it could overload the capacity of the TFO crews, contract crews can supplement the restoration efforts through the contract partner management group.

Attempting to stock all the varieties of conductor, ground wire, pole and steel structures contained in the TVA transmission system is unrealistic. To respond to and recover from severe storm events more quickly, TVA has developed a carefully chosen limited range of material resources to aid in storm recovery. The biggest component is the utility’s emergency steel inventory, which consists of strategic steel-pole and tower-steel materials. As part of the emergency inventory, 12 specific tower types have been designated as emergency replacements for multiple existing structure types. Quantities of steel poles are kept in the emergency stock to replace damaged pole structures as well as certain other tower structures.

The pole class and heights currently in the emergency steel inventory recently were re-evaluated, and it was determined taller and higher-class poles should also be included to align with the structure types being used in current designs. Several repair kits for ground-wire peaks are also contained within the emergency steel inventory to replace minor damage that often occurs to structures on the outlying areas of storm paths.

After widespread damage from tornadoes in April 2011, TVA had 353 transmission structures damaged and 108 transmission lines out of service. The utility was able to restore eight heavily damaged 500-kV transmission lines using 33 towers from stock and 34 161-kV transmission lines using 237 towers and poles from available inventory or construction before needing to order more material to support the recovery effort. The true testament to creating a resiliency plan is the ability to provide a swift recovery response to events like the April 2011 tornadoes.

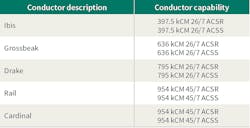

TVA’s conductor supplier provides a value-added service for emergency needs at its conductor manufacturing site to minimize manufacturing time. The steel-core wire inventory has evolved from TVA’s standard aluminum conductor steel-reinforced (ACSR) conductor types to include the equivalent aluminum conductor steel-supported (ACSS) conductor sizes. The MA3 steel core provided in ACSS conductor was selected for the steel core inventory program because it has a higher rate of breaking strength than the standard GA2 steel core in ACSR conductor and has a mischmetal coating adequate for higher operating temperatures. The advantage to this change is the steel core now can be used in both ACSR and ACSS conductor types, if damaged during a storm event.

Drills

TVA’s transmission emergency plan requires an annual emergency drill. The intent of the drill is to demonstrate the ability of transmission and power supply personnel to respond effectively to an emergency in the Tennessee Valley. The drill also provides an opportunity to exercise the incident command system (ICS) of the national incident management system (NIMS).

TVA uses the WebEOC software to centralize event reporting and resource information. Additionally, a transmission emergency operations center (TEOC) layer in its GIS viewer visually can identify the assessed asset damage and provide links to Maximo structure data as well as applicable drawings. Following each drill, TVA determines core capabilities and identifies specific strengths as well as areas of improvement.

Resilience Matrix

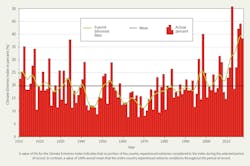

Utilities that have experienced and recovered from major storm damage understand the enormous obligation to mitigate the risks that accompany severe weather and storms. The U.S. National Centers for Environmental Information at the National Oceanic and Atmospheric Administration established a framework to quantify observed climate changes in the U.S. through the development and analysis of the climate extremes index (CEI).

The CEI suggests that the climate of the contiguous U.S. has become more extreme in recent years as shown on the nearby chart. Allstate Insurance has even aired a commercial pointing out that there have been 26 500-year storms in the last decade. Utilities familiar with Hurricanes Katrina, Harvey, Sandy, Andrew, Ike and others have firsthand knowledge of the magnitude of damage these storms produce.

A resiliency matrix framework will help provide a thorough assessment of the design basis, a methodology to harden designs, means to detect and monitor storm events, operating guides, plans for quick recovery and restoration, emergency checklists, emergency drills, references and subject matter experts. Not using such a system could take a toll on a utility and its customer.

Continuing Work

Emergency response will always play a critical role for the utility industry. Emergency events may vary broadly in scope and impact, but the outcome must always be the same—to safely, proficiently and systematically restore the transmission system. A proactive and thorough response must consider external emergency agencies and interdependent utilities and extend to the end customer and community. Understanding the threats to the electric grid by using the resilience matrix has provided TVA the opportunity to document and reevaluate methodologies used for previous storm events while exploring and planning for potential future events.

Brenda Hall ([email protected]) is manager of right-of-way support services in the transmission engineering and construction organization at Tennessee Valley Authority (TVA). Her team is responsible for managing resources, project control functions for schedule and budget, and adherence to regulatory compliance for right-of-way activities. She graduated from Purdue University with a BSCE degree and has a MBA degree from Tennessee Tech. She is a registered professional engineer in the state of Tennessee and has been with TVA for 22 years. Most of her career has been spent in various transmission line project roles.

About the Author

Brenda Hall

Brenda Hall is manager of right-of-way support services in the transmission engineering and construction organization at Tennessee Valley Authority (TVA). Her team is responsible for managing resources, project control functions for schedule and budget, and adherence to regulatory compliance for right-of-way activities. She graduated from Purdue University with a BSCE degree and has a MBA degree from Tennessee Tech. She is a registered professional engineer in the state of Tennessee and has been with TVA for 22 years. Most of her career has been spent in various transmission line project roles.