Keeping It Close: A Composite Solution Redefines Compact Design and Construction

There are several critical customers located in Southern Maryland Electric Cooperative’s (SMECO) territory that depend on an uninterrupted power supply due to the nature of their industry. In 2012 SMECO purchased an approximately four-mile (6.44 km) long radial 69-kilovolt (kV) transmission line that feeds a critical facility owned by an important SMECO customer. The line was originally built in the 1940s and is the primary source of power outside of the facility’s generator system. When the line was purchased by SMECO, it was understood that previous maintenance had been minimal and eventually a significant portion of the line would need to be replaced.

In 2018, after performing routine maintenance and pole replacements as needed, a route study was performed by SMECO identifying that the first 2.5 miles (4.02 km) of line needed to be rebuilt. There were numerous challenges that had to be addressed, including:

- The line would have to be rebuilt while the existing line was energized due to the radial configuration.an abandoned railroad parallel to the line, which had been converted to a hiker/biker trail with significant pedestrian traffic.

- an abandoned railroad parallel to the line, which had been converted to a hiker/biker trail with significant pedestrian traffic.

- that the line traverses part of the Mattawoman Creek watershed, which is recognized to be a critical area by the Environmental Protection Agency (EPA).

Addressing Environmentally Sensitive Areas

The railroad track that was converted into a hiker/biker trail runs through the Mattawoman Creek Watershed, designated by the EPA as a critical area and recognized as a Tier II watershed by the Maryland Department of Natural Resources. Any new development and construction in this area is severely restricted, and construction projects have been denied in the past to protect this area. Acquisition of new right of way for a new line was deemed not feasible for the project and the exiting right of way was to be followed.

Construction Evaluations

The 69kV line is situated along the Northern side of the hiker/biker trail in existing right of way that is shared with the trail. To minimize outages, new tree clearing and environmental impacts, the option chosen was to rebuild the line parallel to the existing line and edge of the pavement. The existing centerline was approximately 15 ft. from the edge of pavement with the conductors attached to cross arms five feet on either side of the pole. The new structures were located an average of 10 ft. (3.05 m) away from the existing structures with approximately 5 ft. (1.52 m) between the new structure and the existing nearest 69kV conductor. This five-foot separation exceeded the OSHA minimum approach distance of 3 ft. 40 in. (.01 m) for 69kV, but by less than 2 ft. (.61 m).

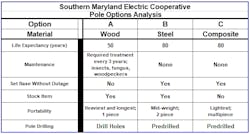

Wood poles are much heavier and would require larger equipment for installation and transportation during construction, increasing the risk of damage to the hiker/biker trail. In addition to being the heaviest of the material options, the wood poles are also the most cumbersome to maneuver. Wood poles must be set as one piece, and there were concerns that minimum clearances could not be maintained from the energized line during the pole setting process.

Composite poles can be manufactured in multiple sections that are shorter than steel pole sections. They are light enough for pick-up trucks to be used to transport each pole section to site. The ability to use lighter equipment helps reduce the risk of damage to the trail and additional costs to the project. Just like steel poles, composite poles are fabricated in sections, and all the pole bases could be set without an outage along the existing route. Steel and composite poles were both higher in cost than comparable wood poles, but they both lowered installation costs by reducing outage requirements.

Minimizing Customer Outages

Several options were considered to minimize the outages required during construction. The option chosen was to install all the bottom sections of the poles first and then set the top halves in two separate segments between dead-ends. Installing all of the lower pole sections at once eliminated the need for any temporary reconfiguration of the existing deteriorated poles. By avoiding temporary hot line transfer of the existing conductors to the new poles, the possibility of existing hardware failure causing an outage during construction was avoided. This strategy of setting all of the pole bases before the pole tops, which shortened the outage requirements for pole setting, only works for multi-section pole designs such as steel and composite poles.

Construction Planning

After finalizing dates with the facility, construction was scheduled to begin in the winter of 2019 to support March outages. Prior to starting, a thorough on-site review of the existing transmission line and overall project was conducted with SMECO, its contractor and county staff to coordinate the closure of the trail. Extensive safety protocols were put into place for pedestrian traffic including portable barriers, signage, personnel dedicated to controlling construction traffic, and continuous trail monitoring.

Outages were scheduled for Thursday through Sunday when the facility was operating with less staff for conductor cutovers. During the first outage, an issue occurred, and facility asked for the line to be quickly returned to service after only one day. Crews were in the middle of pulling wire into the substation, but in less than four hours after SMECO received the call, the line was restored.

With the first section of the line complete, focus turned to the last segment of construction and the facility’s resistance to allow a second extended outage. In order to minimize the second outage to complete the line, a plan was created to have all the conductor installed without requiring an outage.

To ensure there was adequate clearances to set the pole tops safely. SMECO’s contractor surveyed the line on their own to confirm the OSHA minimum approach distances were being met. Once the top pole sections were set, the second outage was only needed to install jumpers and remove poles. This turned out to be prudent, as shortly after the second outage began, one of the facility generators failed. Work was completed and the line returned to service the same day. Construction was completed without the use of heavy equipment and restoration was completed in less than a week.

Construction Complete

Though it was only 2.5 miles (4.02 km) consisting of 55 poles, the rebuild of an existing, radial 69kV line presented numerous challenges to overcome. In today’s world, acquiring new right of way can be detrimental to a project and using existing routes is typically the most prudent option. Because of this, SMECO chose to rebuild a section of line through environmentally sensitive areas in existing right of way to eliminate risk since the rights were already there. Careful coordination between the local government and the facility owner had to be managed to ensure success.

The project team also managed concern through extensive outreach to all affected parties and starting planning early in the process. Communication is always key, and everyone was candid and upfront with affected parties about the construction process and timing. This, in turn, earned their trust that SMECO and the contractor would do what is right. The relationship with the trail staff to this day is paying dividends as they have taken it upon themselves to monitor the line and inform SMECO of line issues before they become significant. Trail staff even does touch-up paint on the base of the poles as a courtesy to SMECO.

From the outset of the project, SMECO realized that their standard construction practices of heavy wire and steel poles would not be ideal. A new type of construction would have to be implemented to reduce construction time and costs while still maintaining safety and reliability. Lightweight composite poles helped SMECO achieve that goal.

The construction team performed admirably throughout by accelerating construction and identifying risks ahead of time. Because of this, the project was completed with only two outages lasting a total of two days when the original plan called for 8 days of outages. It is often thought that the larger the project, the more difficult and challenging it will be. While that is generally the consensus, significant challenges can come with any type of project large or small.

Hugh Voehl III is the Transmission Engineering & Construction director with Southern Maryland Electric Cooperative in Hughesville, MD. Voehl received a B.S. in Mechanical Engineering from the Johns Hopkins University and has over 20+ years of experience in the utility industry.

John Williams, PE is the vice president of the Baltimore office for Booth & Associates. He graduated from North Carolina State University with a BSEE. He is a registered professional engineer and has 22 years of experience designing transmission and distribution projects.

About the Author

Hugh Voehl III

Hugh Voehl III is the Transmission Engineering & Construction Director with Southern Maryland Electric Cooperative in Hughesville, MD. Voehl received a B.S. in Mechanical Engineering from the Johns Hopkins University and has over 20+ years of experience in the utility industry.

John Williams

John Williams has over 25 years of experience working in the energy industry, specializing in gas transportation arrangements in Great Britain and Ireland. John has worked within Pöyry’s Energy practice since 2001, and prior to joining Pöyry worked across Centrica and Shell, working on global gas markets and gas transportation.