Practical Transmission Pole Selection

The pole material selection process is complex, considering the multiple options available in different corrosive and environmental conditions. Pole materials available for transmission utilities include wood, various steel alloys, concrete, hybrid, and polymer.

An understanding of how a pole material ages throughout its service life, what options are available for life extension practices, when to implement them and at what cost, are essential in the pole material selection process. Duke Energy faced the challenge of developing a systematic, practical approach to the process because different types of poles are used in the Duke’s different geographic regions per legacy practices.

With the help of the Electric Power Research Institute (EPRI), Duke Energy established data based on field inspection and associated laboratory testing, and developed a high-level guidance on pole material types and their life extension adders for directly embedded transmission poles.

Various Environments

A good understanding of steel pole corrosion in different environments is vital in a pole life-cycle cost study. Corrosion on a steel pole is typically categorized into zones: atmospheric and sub-grade. An additional zone (transitional) is added to account for compounded effects of both zones such as ultraviolet radiation, contaminants/organic material, thermal stresses, and moisture variations.

Severe corrosion cases traditionally occur within this transitional zone, which extends approximately two feet above and below the groundline of the structure. The EPRI custom report for Duke [2016] provided extensive guidance in this area. Subgrade environment is divided in to R1, R2, R3, and R4 severities, with R1 representing low corrosion and R4 representing the highest corrosion. Atmospheric environment corrosion severity is divided into C1, C2, C3, C4, C5, and CX. C1 to C4 represents none to moderate corrosion, while C5 and CX represent severe to extremely severe corrosion.

The first two tables list the subgrade and atmospheric corrosion environments, respectively. Corrosion rates of bare and zinc coated steel in various subgrade and atmospheric environments are summarized in the third table. The information presented in these tables is compiled using recommended practices established through various industry organizations. These types are general guidelines, and they are helpful in estimating steel pole life in a given environment. However, these rates need calibration studies.

EPRI Field Investigations

The main objectives of the EPRI field investigations were to collect corrosion-related parameters and data for various geographical and environmental conditions present in the Duke Energy system. EPRI established the data based on field inspection of sample steel poles and associated laboratory testing, its expertise, and some analytical modeling. The field inspections include steel wall thickness measurements and condition assessments. The field data collected included: soil type, soil condition, pH, redox potential, soil resistivity, pitting, coating thickness, visual assessment and linear polarization resistance (LPR) values.

In case of weathering steel poles, oxide formation on weathering steel pole surfaces is also measured. The weathering steel alloys can transform into the different oxide formations (goethite, lepidocrocite, hematite, magnetite) and can be visually characterized by adherence, color, texture, pit size depth and density, and lastly patina thickness. When installed within geographic locations containing sufficient wet/dry cycles and low concentrations of chlorides or sulfates, the oxide formation of goethite is formed.

Goethite is a tightly adhered, amorphous oxide that is extremely stable and has a deep purple/chocolate brown color. When structures are installed in unfavorable conditions, other oxides are formed without the protective characteristics of goethite. The collected data helped to understand the types of subgrade and atmospheric environments that prevail in Duke’s system.

Estimating Steel Pole Life

In the case of steel poles, the life of the pole depends on subgrade and atmospheric corrosion environments. For bare steel pole sections, no industry standard models are currently available to estimate the life of corroded sections. The current ASCE 48 [2011] standard on steel poles provides equations to calculate the capacity of a 12-sided steel pole section. Per this method, the permitted stress in the steel section decreases with the increase in ‘flat width (w)/thickness (t)’ ratio to account for local buckling considerations.

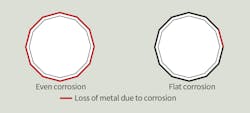

Corrosion of a steel pole section (loss of thickness) effectively increases the ‘w/t’ ratio and this leads to reduced capacity of the pole section. In addition, bending stresses and axial stresses increase due to the reduction in section modulus and cross-sectional area. Two different scenarios can be considered: even corrosion all around the pole (all 12 pole flats) and flat corrosion (one pole flat).

If a steel pole utilization under the extreme load is less than 100% (let us say 95%), then the loss of thickness needed to stress the pole section to 100% utilization ratio can be estimated. By knowing the rate of corrosion in different environments (see the third table on previous page), the life of a steel pole section for a given thickness loss is calculated in this study. For a given pole, these calculations are performed for both even and flat corrosion scenarios, and the worst of the two is considered in this analysis. For example, in the case of a 75 ft (22.86 m) H2 steel pole in an R1 subgrade environment assuming 95% utilization, the bare steel pole life is estimated at 19 years under the “even corrosion” scenario.

Steel Pole Life Extension

Depending on the type of environment, different types of life extension adders such as coating systems, ground sleeves, engineered (controlled) backfills, galvanizing, cathodic protections can be used. Corrosion-inhibiting coating with an aliphatic UV protection is typically used to protect steel poles. Ground sleeves are considered a sacrificial barrier that will provide many years of service without additional maintenance. The life estimate methodology used for the bare steel pole is used for ground sleeves as well.

Engineered backfills can eliminate the effects of soil stresses due to frost heave or movement due to superior drainage and reduce the time of wetness. The type of aggregate may also help control the pH (acidity) of the environment and help maintain the passivation layer of the zinc carbonate in the event of a coating system failure. Galvanizing systems provide some measure of protection to the structure substrate when exposed to the sub-grade environment. Cathodic protection systems have traditionally been employed in sub-grade or immersion service. The need for external cathodic protection may be anticipated by making soil corrosivity measurements in field surveys, and then systems may be designed to meet those requirements.

For example, magnesium anodes are very effective external anodes that protect the corrosion of the outside surface of a steel pole and they can be designed to extend pole life from 10 to 25 years. EPRI’s Charlotte facility conducted a study to understand effectiveness of anodes.

Development of Categories

Using the (1) pole material life data (2) pole inspection, repair and replacement cycles and (3) the associated pole material, installation, and maintenance costs, a financial model was developed considering Net Present Value (NPV) analysis. The poles considered in the financial study include directly embedded transmission poles of steel, concrete, wood and hybrid (concrete base with steel top). Three different pole heights/classes (75 ft./H2, 80 ft./H5 and 100 ft./EH8) were used in the analysis. FRP poles and laminated wood poles were not considered.

For the analysis and standardization, three distinct combinations of categories I, II, and III were developed (see the fourth table). For environments I and II, steel poles were identified as primary preferred material types for all Duke regions. Concrete poles were also a choice in two regions. Multiple life extension adders are required for steel poles in Category II due to the severe subgrade environment. In category III, concrete pole is a preferred choice because both atmospheric and subgrade environments are severe. The implementation of these recommendations is under review and progress.

This study uncomplicated the complex. Duke and EPRI found that both the installation conditions and corrosion severity were two key variables in the pole selection process, and they came up with a systematic, practical approach to pole material selection.

Acknowledgements

The authors wish to thank Jimmy Robinson (lead investigator), Andrew Gould, Rick Nugent, Hector Cruz, Jeff Erdle, Paul Jakob, Bill Carnahan, Jared Kugelman, Tim Snow and Larry Dorman for their contributions.

About the Author

Prasad Yenumula

Dr. Prasad Yenumula is a principal engineer at Duke Energy. He is the chair of the Line Design task force of EPRI and the past chair of the CEATI-TODEM interest group. He is active in various other industry organizations such as ASCE, NESC, EEI, DFI, and ANSI C29. Yenumula is also a professor (adjunct) at Gonzaga University. He is a founding faculty member of the T&D engineering Masters program. He recently co-authored a textbook on transmission line structures and foundations.

Neal Murray

Neal Murray is a technical executive at the Electric Power Research Institute. His focus is corrosion within T&D and substations with more than 35 years of experience in corrosion control, product development, and program management. Murray has a BS in mechanical engineering from Gannon University and is active in NACE, ASTM G01, and IEEE PES.