Michigan Line Rebuild Goes the Distance

In the mitten shape of Michigan — along the bottom of the palm — sits Marshall, a community in the south-central part of this U.S. state with a population of 7000. Well known for its historic 19th- and early 20th-century homes, the keeper — or national register chief — of the National Register of Historic Places has referred to the town as a “virtual textbook of 19th century American architecture.”

While a well-preserved historic home is of value, historic power lines often are another story. For many years, Marshall, like countless communities across the country, was reliant on an aging power grid well past its prime. Portions of the electric transmission grid in Michigan were built more than 50 years ago and only recently have started experiencing reinvestment in them. Michigan is not alone.

According to the 2017 American Society of Civil Engineers (ASCE) Infrastructure Report Card, “Most electric transmission and distribution lines were constructed in the 1950s and 1960s with a 50-year life expectancy, and the more than 640,000 miles (1.03 million km) of high-voltage transmission lines in the lower 48 states’ power grids are at full capacity.” As for its grade, U.S. energy infrastructure received a D+.

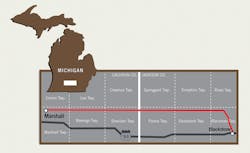

ITC Holdings Corp., the country’s largest independent transmission utility, is at work systematically modernizing electric infrastructure across its seven-state footprint. Within that territory, the town of Marshall’s electricity needs have been long served by ITC’s Marshall-Blackstone 138-kV transmission line. Yet, in recent years, growing power demand, an increasingly electrified world and outdated infrastructure technology have been taxing the line’s service capabilities, creating a potential for the line to become overloaded. Aged structures along the 34-mile (55-km) line were deteriorating, and obsolete conductors needed to be replaced. ITC decided to rebuild.

An ITC Rebuild

The decision to fully reconstruct rather than repair the line was based on multiple factors. The existing line had small old copper conductors that can struggle with the higher loads necessary to support 21st-century power demand. Not to mention, the aging towers — originally designed before World War II for windmills — were straining to support the lines.

Transmission engineers in the 1940s and 1950s realized if these towers could hold up a windmill, they could support power lines and conductors. These structures helped to transmit electricity to communities, towns and businesses across the country for decades. After decades on the job, it was time for the lines to be retired.

“We’re very focused on keeping the lights on and rates very manageable, particularly for businesses and the senior residential community,” said Ed Rice, director of electric utilities for the City of Marshall. “The line had served its life and done a nice job for the community, but it definitely needed support.”

Shoo-Fly Line

Before the project got underway, the City of Marshall, which operates as a municipal utility, had one request of ITC: the city must not go down to a single transmission source during construction of the new line.

With one line being out of service, if the other line went out, the city would be in the dark for however long it took to restore the line. ITC was sensitive to this and accommodated the town’s concerns by creating a temporary backup line, known as a shoo-fly line. The shoo-fly line created a tap into another existing line, providing a short-term second source of power to the city during construction.

Securing the Permits

As most in this industry know, one major step comes between planning and execution: permitting. On the Marshall-Blackstone project, these authorizations included wetland permits, soil erosion permits, driveway permits, county permits and U.S. Department of Transportation permits, to name a few. It took more than six months to secure all the necessary authorizations, and by the end of the project, the number of permits totaled 23.

Any transmission project can bring opposition from residents, but because of ITC’s forward-looking community outreach, the response from Marshall and surrounding areas was largely positive. Residents could see with their own eyes this line was something that would benefit their town and improve the system.

Construction Challenges

When the ITC team started getting familiar with the project, they soon realized the line was built originally on some of the most challenging terrain in Michigan. More than 30% of the ground the line cut through was wetlands.

In addition to wetlands, the right-of-way for the Marshall-Blackstone line traversed farm fields and residential areas. This created a challenge because large trucks and heavy equipment could damage the land by causing deep ruts and compaction. Over the course of the project, ITC’s field crews used 64,000 timber mats to protect the ground surface as well as to prevent soil erosion and sedimentation problems. This was a significant but necessary undertaking. Each mat is 4 ft to 6 ft (1.2 m to 1.8 m) wide, 16 ft (5 m) long, 1 ft (0.3 m) thick and weighs more than 2000 lb (910 kg).

Another construction challenge was the need for a large quantity of reinforced concrete foundations, which required more than 4700 cu yard (3593 cu m) of concrete. In total, the project team designed and constructed 330 structures, which included 179 direct-embedded poles and 151 poles on reinforced concrete foundations. On a standard power line design, about 15% to 20% of the poles require drilled-pier foundations to anchor the poles deep into the ground. On the Marshall-Blackstone project, about 45% of the poles needed the reinforced concrete base, given the geotechnical conditions.

Each foundation is substantial, ranging from 5 ft to 12 ft (1.5 m to 3.7 m) in diameter and reaching anywhere from 16 ft to 67 ft (5 m to 20 m) deep in the ground — until it hits good soil. In wetlands like those ITC encountered near Marshall, the foundation ranged from 40 ft to 50 ft (12 m to 15 m) down before reaching suitable earth. It also is crucial to apply silt fencing around the foundation, serving as a barrier between the pier and the nearby body of water, to prevent mud and silt from dispersing to the detriment of animals and plants.

Sustainability

Few industries are as in touch with nature as utilities, and ITC is no exception; environmental excellence has always been one of the transmission utility’s driving principles. This ethic begins in the utility’s workplace and extends to building, operating and maintaining grid systems, as well. From the start of the Marshall-Blackstone project, protection of the environment, particularly the wetlands, was crucial.

Preventing soil erosion and controlling sedimentation was one of the most important components of the build. The permit for this work involved best management practices to ensure construction would not negatively disrupt the hydrology, or the movement of water on the ground, and would not put a great deal of sediment into surface waters. In the era in which the original line was constructed, projects like this often would result in a great deal of sediment and silt going into streams and lakes. It was considered to be the price of progress. Today, ITC and other utilities devote valuable time and immense effort to ensuring the environment surrounding these project sites is protected.

Worker Safety

Protecting workers also is of paramount importance on construction projects. At its peak, the Marshall-Blackstone project had 50 experienced construction workers on-site to build the 34-mile line and install about 140 miles (230 km) of conductor. ITC’s construction partner on the project was M.J. Electric, a construction management company under the Quanta Services banner.

M.J. Electric shared ITC’s emphasis of safety on the Marshall-Blackstone project, starting every morning on-site with a reminder of safety protocols as well as extensive stretching exercises to ensure the workers were limber and ready for the day’s physical work. As a leader in field safety, ITC was proud to report there were no serious injuries on this challenging project.

Improved Reliability

Ultimately, the Marshall-Blackstone project was highly successful and a rewarding example of the power of extensive planning, teamwork, environmental protection and worker safety. As a result, the charming city of Marshall is more than adequately powered for decades to come. The community also benefited by the positive economic impact of the rebuild, with the crew spending money at local hotels, restaurants, stores, laundromats and more over the course of two years.

Where Marshall had one and a half power feeds before, there are now three feeds. It really gives the community a lot of confidence in the reliability of the ITC system that power will keep flowing into the city. Not only do residents and surrounding areas benefit from rebuilds like this, but they also have enabled ITC to improve the performance of its three interconnected transmission systems steadily since being acquired in 2003. Through 2016, the utility has reduced the average number of outages by 40% at ITC Transmission, 20% at Michigan Electric Transmission Co. and 49% at ITC Midwest. These vitally important measures of reliability are at the core of ITC’s operational excellence across a wide footprint. That resilience begins and ends with lines like Marshall-Blackstone. ♦

Bob Schultz is a senior project manager with degrees in engineering and business administration from the University of Michigan. He is a member of IEEE and has led industrial project teams since the mid-1980s.

Hasib Bhuiyan is a senior design engineer with a degree in civil engineering from the University of Wisconsin. He has worked in the utility industry with a focus on transmission line design for nearly 18 years.

About the Author

Bob Schultz

Bob Schultz is a senior project manager with degrees in engineering and business administration from the University of Michigan. He is a member of IEEE and has led industrial project teams since the mid-1980s.

Hasib Bhuiyan

Hasib Bhuiyan is a senior design engineer with a degree in civil engineering from the University of Wisconsin. He has worked in the utility industry with a focus on transmission line design for nearly 18 years.