Slovenia Advances Line Protection

Elektro Primorska, a distribution utility in Slovenia, began using semi-insulated overhead line conductors on its 20-kV networks in the early 21st century. Since being installed, these semi-insulated conductors have caused major problems as a result of poor installation, poor construction standards and the use of inappropriate materials. Furthermore, as a result of frequent lightning storms in this region, the utility has experienced supply interruptions caused by grounded conductors.

Since most of these interruptions involve high-resistance faults with a grounded conductor, they pose a high risk of death or serious injury until the fault is located and the overhead line de-energized. Fault location could take anywhere from a few hours to, in some instances, several days. To protect the people who lived in close proximity to these overhead lines, Elektro Primorska took action to minimize the safety hazard.

To address the issue of undetected grounded conductors, the Association of Slovenian Electricity Distributors banned the use of semi-insulated conductors on overhead line networks in 2004. This applied to Elektro Primorska and several other Slovenian distribution utilities using semi-insulated conductors on their overhead lines. This remained a statutory obligation until a comprehensive study to investigate the causes and consequences of broken semi-insulated conductors was completed and guidance was provided on construction standards.

Protection of Overhead Lines

Generally, the supply interruptions attributable to broken or grounded conductors are detected and isolated from the remaining sections of the healthy distribution network by means of classic earth-fault current protection. However, on occasion, this form of protection can fail to operate if the ground resistance is too high, resulting in an earth-fault current too low to be detected.

There are several reasons for this, such as the broken conductor was not in direct contact with the soil because of the conductor insulation or because it was in contact with soil in a rocky or sandy terrain. In these situations, the electrical resistance at the point of contact is very high, creating a high-resistance (relatively low-current) fault. Alternatively, the design and configuration of the distribution network in the form of long overhead lines, different earthing systems or unearthed construction standards can result in insufficient earth-fault current to activate the protection when a broken semi-insulated overhead line conductor is grounded.

The Elektro Primorska distribution network consists of 700 km (435 miles) of 20-kV overhead lines strung with semi-insulated conductors. To develop a solution for the problem of grounded semi-insulated overhead line conductors, the utility acquired the services of two Slovenian companies, C&G d.o.o. Ljubljana and Kolektor Sinabit d.o.o.

Line Protection System

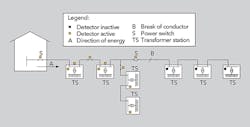

The LiSa overhead line protection system patent is jointly owned by C&G d.o.o. Ljubljana and Kolektor Sinabit d.o.o. The system detects and identifies the location of broken conductors of all types, including bare conductors, and at all voltage levels by placing detectors on the overhead line.

The measurement of the secondary voltage, or low voltage, in a 20-kV low-voltage transformer station with the appropriate network analyzer only gives information about unidentified failures on the 20-kV overhead line, such as fuse failures, conductor breaks and power failures. This procedure eliminates ambiguous information on downed conductors.

To obtain the information on broken conductors, it is necessary to interrogate the primary side of the transformer. The LiSa system allows the reception and processing of information from the primary and secondary sides of the transformer. Using this information, signal failures, broken 20-kV conductors, medium-voltage fuse failures and operation of transformer protection are detected and analyzed. This method confirms whether the overhead line has broken conductors and, therefore, has to be de-energized directly or indirectly by the remote control center (RCC).

The indicator or detector can directly or indirectly isolate a line through the RCC or notify the RCC of a failure. Then the Elektro Primorska duty engineer can notify the maintenance team, which can then determine the type and location of the damage to conduct the necessary fault repair work. The important thing is not how the fault detection is determined, but how the detection techniques are employed, as they must satisfy Slovenian and European patents.

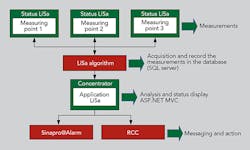

The design of the overhead line protection system includes several primary functions:

- Measure the voltage at the nodes on the distribution power network

- Aggregate the data from the data remote terminal unit (RTU), which is transmitted through telecommunications channels to the concentrator device

- Process all transmitted data, comparing the values from all measuring points on the power network using an algorithm that determines the status of the power network

- Transmit an alarm in the RCC, sending a short message system (SMS) to the responsible personnel who remotely disconnects the faulty overhead line.

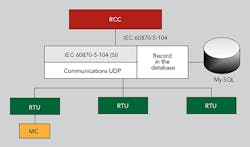

The control system consists of several individual components including a central location, RTU, communications or measuring point, and graphic interface application. The central location is the server software that includes software packages for data transfer, the protection algorithm, measurement analysis, and alerting or messaging signaling.

The RTU provides the following:

- Data collection and management of measuring centers and other intelligent devices through the communications connections with devices (RS232, RS485, Ethernet)

- Signal data collection and control of devices through auxiliary/signal contacts or device interfaces (the state of switching and protection devices, collection of analog measurements, connecting/disconnecting devices, etc.)

- Unified control of all sub-assemblies included for different functionalities, such as monitoring security of supply, measurements of voltage quality, monitoring of operating parameters and control management

- Local recording of all scanned status information, measurements and events, which are equipped with timestamps when being transferred to the RCC

- Implementation of local data transmitted from the control center.

The concentrator device contains information from remote locations, periodically scanned and stored in a database on the server. This data is available for the use of various investor services and activities. It also checks and indicates the status of equipment. In the event of an alarm condition, data from the faulty equipment is immediately transferred to the center. Information regarding security and operational parameters is transferred to the distribution system management center (the RCC) in accordance with the IEC 60870-5-104 protocol. Parameters and commands for the statuses of equipment are transferred in the opposite direction — from the RCC to remote locations — using the same protocol.

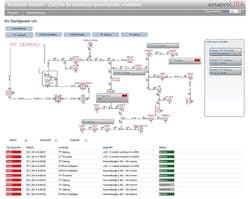

The basic functionality of LiSa is the detection of errors and failures on the medium-voltage distribution network and at transformer stations, and the implementation of automatic disconnection in case of detected broken semi-insulated overhead lines. Fault detection algorithms are carried out under all possible operating conditions, taking into consideration the possibility of damage and the topology of the medium-voltage distribution network. On the supervisory control and data acquisition system in the RCC, the system will release only critical detected failures not detected by any other electrical protection.

The server application also has an integrated Sinapro@Alarm with an SMS and email alarm that notifies personnel about detected faults on the system. Users can perform a review and analysis of acquired data online using MiSMART.

Pilot Project

In 2006, Elektro Primorska decided to equip some sections of its 20-kV overhead line network conductors with the LiSa system to protect it from the dangers of interrupted overhead lines with covered conductors. Elektro Primorska equipped several 20-kV overhead lines with the system, for example, on its 20-kV outgoing circuits from a 110/20-kV substation. The detectors are installed in the following locations on the 20-kV overhead lines: the 20-kV side of the outgoing feeder at the beginning of the overhead line; at the termination of a 20-kV overhead line supplying a 20-kV/LV substation; and on a 20-kV pole-mounted auto-recloser positioned in the middle of the overhead line circuit.

Elektro Primorska thought the system should include additional devices (measuring points), so the protection system is able to detect downed conductors by measuring the voltage asymmetry on the three-phase system. The section of the Elektro Primorska medium-voltage overhead line routed through a mountain and forest environment was equipped with covered conductors and the LiSa system.

After several years of testing, the system has successfully operated since 2012, providing the protection required to disconnect faulty overhead lines. The system also is used for measuring power quality in accordance with the Standard EN 50160 and for alerting and communicating events. The system’s operation has proved to be very reliable in the detection of defects and grounded conductors.

A Safer System

The problem of identifying the location of grounded overhead line conductors has been an issue throughout the history of overhead lines. Many circuits, even those with bare overhead line conductors and at all voltage levels, are subject to supply interruptions; often the location cannot be detected by the industry’s standard protection systems.

Acknowledgement

The authors wish to thank and acknowledge the support of Viktor Lovrenčić of C&G d.o.o. Ljubljana and Samo Ceferin

of Kolektor Sinabit d.o.o for the development of the LiSa system, and for the installation and monitoring of this equipment now installed on Elektro Primorska’s distribution network.

Zvonko Toroš ([email protected]) received his bachelor’s degree from the Faculty of Electrical Engineering in Ljubljana and joined Elektro Primorska as a trainee. Since then, he has held various positions in the utility, progressing from roles such as system designer to that of director of the technical sector. Currently, Toroš serves as advisor to the president of the management board. In March 2003, he earned his master’s degree from the Faculty of Electrical Engineering and Computer Science in Maribor; in June 2009, he received his Ph.D. He is president of the Slovenian National Committee of CIRED, a member of IEEE and CIGRE, and a member of the Slovenian TP Smart Grid.

Benjamin Turnšek ([email protected]) graduated from the University of Ljubljana, Faculty of Electrical Engineering. He has 11 years engineering experience with distribution utility Elektro Primorska, working in the areas of power quality, protection and remote control of the electrical power system and as a project manager. Turnšek also has worked as the project manager for the implementation of the LiSa system at the utility.

Mentioned in this article:

C&G d.o.o. Ljubljana | www.c-g.si

Elektro Primorska | www.elektro-primorska.si

Kolektor Sinabit d.o.o. | www.kolektorsinabit.com

Modbus | www.modbus.org