Eskom Investigates How to Improve Lightning Performance

South Africa has an extensive medium-voltage overhead line electric distribution network supported mainly by wood poles. The predominant voltage is 22 kV between phases. Some of the lines traverse areas with high lightning ground flash density, greater than 14 flashes/sq km annually (36 flashes/sq mile annually). Other lines supply customers in areas with relatively low ground flash density but sparse vegetation, so the overhead lines are vulnerable to direct lightning strikes.

South Africa also has sizeable populations of endangered large birds like vultures, which need to be protected from electrocution. Additionally, much of the coastal (and some other) areas are prone to excessive insulator pollution, resulting in leakage currents that may lead to the burning of wood pole structures. These factors and others, such as construction and maintenance costs, need to be factored in when designing an overhead distribution line.

Eskom, the country’s largest electric utility, has conducted a study on the lightning performance aspect of medium-voltage (MV) overhead line design, using the experience it has gained in South African conditions. Alternative configurations have been evaluated and their performance compared with that of the standard configuration.

Standard Configuration

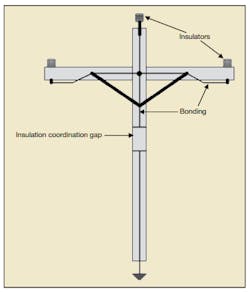

The standard configuration of MV overhead line design is a partially bonded wood pole structure, with a wood crossarm and earthed-end pole-top metal hardware bonded together and connected to earth by an insulation coordination wood gap. This gap increases the lightning impulse insulation level of

the structure from the approximately 150 kV provided by the insulators to about 300 kV.

This configuration has the advantage that induced lightning surges do not cause a flashover because the insulation level is greater than the voltage of such surges. However, should a flashover occur because of a direct lightning strike, the arc-quenching properties of the wood insulation coordination gap means the protection does not necessarily work. The wood gap also improves bird safety because it adds an impedance into the earth path, often in the mega-ohm range.

Because induced lightning surges do not cause flashovers, terminal equipment such as transformers and their surge arresters are likely to be stressed more than they would be if the overhead line had a lower insulation level. Also, because direct lightning strikes still cause flashovers, the supporting structures need to be designed to withstand the high energy associated with direct strikes as well as the resulting power frequency follow-through current, which can damage the pole in some cases.

One way of achieving this design feature is to mount a spark gap across the insulation coordination gap. Pole fires also can, in rare cases, be started in the insulation coordination gap because of the lightning flashover and follow-through current. Overall, however, the standard configuration has performed well in the field, as it provides a reasonable compromise between the various constraints on overhead line

performance, safety and cost.

Fully Bonded And Earthed

Recent research has focused on reducing stress on terminal equipment, while maintaining acceptable performance of the overhead line. The typical approach taken has been to remove the insulation coordination gap in the earth down wire, thereby reducing the lightning insulation level to that of the insulators, namely 150 kV. This modification has the advantages of preventing damage to a wood pole from an overhead line flashover. Therefore, it reduces the number

of lightning surges to which transformers, fuses and other components are subjected.

The results of this are promising from a lightning performance perspective. A different version of this configuration is to include an extended air termination at the top of the pole, as other research studies suggest this may help to reduce the number of lightning strikes to overhead line conductors. It often is reported that a high percentage of lightning strikes to transmission lines hit the supporting towers rather than the conductors in mid span; similar observations have been made about distribution lines.

The fully bonded and earthed configuration poses a significant electrocution risk to large birds, because earth potential is transferred to the top of the pole by the earth down wire, now without a gap. The risk is increased if a steel crossarm is used. Circuit breakers also are likely to be stressed more, as they need to operate more frequently because of the increased number of flashovers on the line.

Therefore, Eskom sought a compromise between the 300-kV and 150-kV lightning impulse insulation level options. It has pursued a configuration where the size of the insulation coordination gap is reduced and mounted away from the surface of the wood pole, with a substantially larger wood gap than air gap. This configuration removes the direct connection between the pole-top hardware and earth. The expected lightning impulse insulation level of this configuration

is approximately 200 kV.

Comparing Options

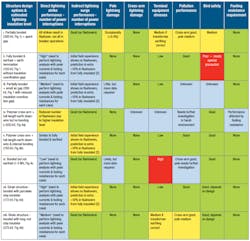

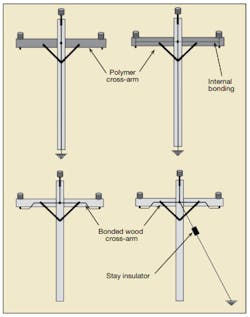

Alternative options include the use of polymer crossarms — with no crossarm bonding or with internal crossarm bonding — and removal of the earth down wire, yet retaining the crossarm bonding and strain structures with short or long stay-wire insulators.Comparing the different options, the partially bonded configuration is expected to be the best in terms of lightning protection, based on the information currently available. There also is extensive operational experience available for this configuration. Other options could potentially offer a similar or improved performance than partially bonded structures, but they would require further investigation and validation. For example, the partially bonded option with a smaller insulation coordination gap has only recently been piloted in the field, so information is insufficient at this stage to fully evaluate its performance.

Options that use polymer crossarms may be bird friendly and offer acceptable performance in all other aspects. Such crossarms have not been used historically in South Africa, so there is a lack of experience from which to draw conclusions. Bonding, but not earthing, has the advantage of offering better pollution performance than fully insulated structures and, therefore, may be considered for use on aging fully insulated overhead line networks with high pole-top fire risk, where, for example, an old pole needs to be replaced. This option has the disadvantage of high terminal equipment stresses from lightning surges caused by the line’s high insulation level.

Lab And Field Testing

Eskom’s lightning impulse withstand voltage, corrected to standard temperature and pressure, was determined for

several pole-top configurations, including some with shorter insulation coordination gaps. It was greater than 200 kV in all cases, with several configurations yielding more than 300 kV, depending on the insulator used. These results support the initial indication that a lower lightning insulation level may be feasible. However, the effect of soil resistivity requires further consideration.

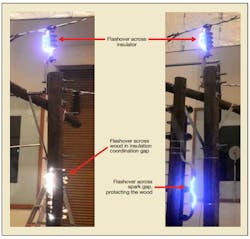

A disadvantage of partial bonding to a 300-kV insulation level is flashovers may damage a pole in the insulation coordination gap. Mounting a spark gap across the insulation coordination gap could prevent this damage. This spark gap configuration has been deployed in areas where pole damage from lightning (and the resulting follow-through current) was at an unacceptable level. In areas where performance data is available, only two out of 756 poles where the spark gap was installed failed in the first few years since installation, a failure rate of less than 0.4%. Both failures occurred on relatively new poles with flashover suspected to have occurred in the pole.

The failures could be attributed to the relatively high moisture content — and, hence, conductivity relative to air — of the new poles. Measurements of wood resistance as a function of age support this phenomenon, but in any case, the failure rate is very low. An example of where installation of this spark gap configuration has been a success is on a section of overhead line that runs through a salt pan in the arid Northern Cape province of South Africa. The soil resistivity is expected to be low in the pan, and field staff regularly had to replace one of the structures. This pole has not had to be replaced since installation of the spark gap about four years ago at the time of writing.

The lightning impulse insulation level of a 16-km (9.9-mile) staggered vertical structure overhead line was changed from 300 kV to 150 kV. The pole was fully bonded and earthed with the earth wire extended to about 250 mm (9.8 inches) above the highest phase conductor.

The number of lightning strikes on this feeder — during a two-year period while the lightning impulse insulation level was 300 kV and for the first two years after it was changed to 150 kV — was recorded. No flashovers occurred from indirect lightning strikes during this time, indicating the arc-quenching capabilities were not reduced after the reduction in insulation level and, therefore, the reduction in insulation level warrants further investigation.

Summary

The configuration of a partially bonded structure with a lightning insulation level of approximately 300 kV has performed more than adequately over several years and much field experience is available. However, Eskom’s initial experience with alternative configurations indicates its network performance could be optimized by, for example, using a smaller insulation coordination gap.

This configuration and others require further investigation before they can be considered for large-scale deployment. In addition to technical criteria, this investigation also should include life-cycle cost and the practicalities of construction and maintenance. It may prove necessary to use a certain configuration in certain areas because of differences in local conditions. Until Eskom can investigate the alternative configuration further, it will continue to use the partially bonded configuration.

Acknowledgments

This article was first published in the proceedings of the 25th International Conference on Electricity Distribution (CIRED) in June 2019 in Madrid, Spain. The authors of this article were joined by Hendri Geldenhuys and Willem Dirkse Van Schalkwyk, also of Eskom Holdings SOC Ltd., and John Van Coller, of the University of the Witwatersrand in Johannesburg, South Africa.

Manie Kotzé, Ockie Fourie and John Coetzee, of Eskom, are thanked for their assistance with much of the field work. Willem Bisschoff, of Eskom, is thanked for his work with respect to the laboratory tests. Kotzé, Coetzee and Bisschoff have since left Eskom’s employment.

Andreas Beutel ([email protected]) holds BSEE and MSEE degrees as well as a Ph.D. in electrical engineering from the University of the Witwatersrand, South Africa. He is currently chief engineer at Eskom Holdings SOC Ltd. His research interests include electrical distribution, insulation and safety, and lightning and surge protection. Dr. Beutel is a registered professional electrical engineer in South Africa, a Chartered Engineer in the UK and a Fellow of the South African Institute of Electrical Engineers.

Bruce McLaren ([email protected]) holds a national diploma in electrical, a graduateship in electrical distribution from the City and Guilds of London Institute, and a post-graduate diploma in project management. He is a senior technologist at Eskom Holdings SOC Ltd. McLaren’s research interests include medium- and low-voltage electrical distribution, including applied insulation, safety and lightning mitigation. He is a registered Professional Electrical Technologist in South Africa and a member of the South African Institute of Electrical Engineers.

About the Author

Andreas Beutel

Andreas Beutel ([email protected]) holds BSEE and MSEE degrees as well as a Ph.D. in electrical engineering from the University of the Witwatersrand, South Africa. He is currently chief engineer at Eskom Holdings SOC Ltd. His research interests include electrical distribution, insulation and safety, and lightning and surge protection. Dr. Beutel is a registered professional electrical engineer in South Africa, a Chartered Engineer in the UK and a Fellow of the South African Institute of Electrical Engineers.

Bruce McLaren

Bruce McLaren ([email protected]) holds a national diploma in electrical, a graduateship in electrical distribution from the City and Guilds of London Institute, and a post-graduate diploma in project management. He is a senior technologist at Eskom Holdings SOC Ltd. McLaren’s research interests include medium- and low-voltage electrical distribution, including applied insulation, safety and lightning mitigation. He is a registered Professional Electrical Technologist in South Africa and a member of the South African Institute of Electrical Engineers.