White Storks and Distribution Lines

As the main energy distribution system operator, EDP-Distribuição – Energia S.A. (EDP-D) in Portugal is committed to incorporating respect for the environment and management of environmental aspects in all phases of business processes, increasing the quality of supply, and minimizing outages and economical losses. EDP-D operates approximately 83,000 km (51,576 miles) of 60-kV high-voltage (HV) network and 10-kV to 30-kV medium-voltage (MV) network lines and cables supplying about 6.1 million customers.

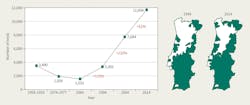

The number of white stork nests in Portugal has increased by about 50% in the last decade, according to preliminary results of the national census of the species. White storks use electrical distribution poles as nesting places in Portugal and parts of Spain. Therefore, this population increase represents an increase in the demand for nesting and roosting on MV and HV electrical distribution equipment (10-kV to 60-kV networks). This has resulted in frequent bird fatalities from electrocution and recurrent outages of power supply because of the activation of the automatic safety protection devices.

White storks are among the birds in Portugal most seriously affected by electrocution and a source of financial issues for electric utilities and industrial clients, because the storks use electric poles as nest substrates. Electrocutions occur in areas where perching activity on the poles does not have enough spacing to accommodate the stork’s large wingspans and height.

White stork nest growing in Portugal (2014 – last national census of the species).

Action to Deter Nesting

Over the past 50 years, EDP-D has developed many techniques and used different types of equipment to deter birds from critical locations, such as airports, aquaculture ponds and electricity overhead lines. To control the main parameters of power quality (voltage level and continuity of service), EDP-D, in collaboration with the Institute for Nature Conservation and Forests (ICNF), developed a program to clear nests and residue from network poles as well as installing anti-nesting and anti-roosting devices in areas frequented by storks. In addition, dedicated nesting platforms were built to replace the loss of potential nesting places. At present, the standard dissuasion devices to prevent nesting and roosting are as follows: passive wind turbines, metallic umbrellas, slanting (45-degree) metallic plates and triple chevrons.

Despite these measures to minimize power outages and bird fatalities, nesting remained. Additionally, bird-related incidents with outages are increasing. Furthermore, bird-related incidents had a large impact on the technical service quality (TSQ).

Examples of white stork nesting, even when deterrent devices are installed: (a) wind turbine blocked by a stork nest, (b) nest over insulators and lines, (c) nest under chevron and over high-voltage switch, and (d) large stork nest over power lines.

Some of the technologies developed and tested included, from left to right, motorized turbine, sound system and vibrating platforms.

Stork Risk Mitigation

Growing environmental awareness encourages electric utilities to create innovative solutions that overcome challenges like white stork nesting. Losses to industry and electric utilities coupled with an increase in the number of bird deaths was the motivation behind the stork risk mitigation project. The objective of the project — which involves EDP-D, the Institute of Systems and Robotics (ISR-UC) and the life sciences department of the University of Coimbra (DCV-UC) — was to develop and implement sustainable and harmless technologies such as vibration devices, powered turbines and micro-electroshock dischargers to prevent nesting and roosting.

Distress and alarm calls are communicated by many species of birds when in danger; therefore, these calls may be useful to disperse birds of the same species or other related species. Several commercial sound systems are available. However, published data on effectiveness in dispersing birds is scarce. Another commercially available technique is the broadcast of ultrasounds, yet this is not particularly effective since most bird species do not perceive ultrasounds.

Sound systems with distress calls are effective on storks but have a high negative social impact on residential areas. People complain about the noise, and vandalism acts directed at the systems were observed, accompanied by theft of equipment. In rural areas, the sound systems also repel other species from their habitat. In hunting areas, these sound systems have been silenced with shotguns.

Powered turbines and vibrating platforms are highly effective for roosting prevention, but their power sources are expensive. The mechanical systems also require additional periodic maintenance, which increases the operating expense.

A Shock System

EDP-D decided to develop a micro-electroshock system to control the activity of storks. The goal was to minimize the damage caused by their activity and prevent electrocution. The system developed is based on controlled electric discharges, with a very low amount of energy to the storks when they try to land on the line structures. The discharge causes an unpleasant experience without inducing significant disturbance to stork life. The micro-electroshock shock technology is equivalent to that used frequently to control small birds (such as pigeons) on monuments, cathedrals and other qualified buildings. The low-energy discharge sufficiently induces discomfort but is completely harmless to the bird.

In the absence of literature about controlled micro-electroshock shock systems on the white stork species, tests were conducted to examine the amount of energy required to apply this kind of stimulus to induce a feeling of discomfort yet be harmless to the bird. For these tests, a platform with comb-type electrodes was built with energizer equipment to deliver 1-joule and 2-joule micro-electroshocks. The equipment was tested on turkeys that have a similar body mass to storks.

The tests confirmed there is no reaction to the micro-electroshock stimulus applied to the bird feathers, because the feathers act as an insulator. Therefore, it is considered harmless for storks without causing them any vital disturbance.

(1) Due to stork incidents in last five years: (2) Minimum number of traditional prevention equipment that needed to be replaced in order to turn the solution profitable has been calculated.

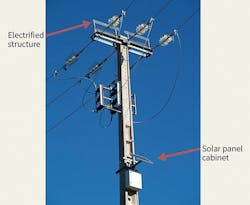

Installation model for standard micro-electrical system pole.

The stork mitigation program involved the implementation of originally produced or modified nonharmful repelling technologies:

- Set of electrified structures

- Electrifier equipment

- Independent power supply.

The energizer was a certified market model that supported the requirements and protection standards. The low power consumption of the system (3.2 W) was one of the key requirements to enable the usage of 12-V battery and solar panels. The amount of discharge energy can be adusted between 1 joule and 2 joule at 9800 V, and the period between discharges was 1 sec or 2.5 sec. The independent power supply was a solar panel with the charge controller and battery installed inside the cabinet.

The energizer produces a pulse that has an extremely short duration, less than 100 msec, with very limited energy transfer. The input circuitry takes electrical energy from the supply (alternating current main or battery) and charges the main storage capacitor. The timing control sends a signal at regular intervals to the power switch, which discharges the capacitor. The pulse-shaping circuitry shapes the energy through a step-up transformer onto the discharge electrode. Once the capacitor is discharged, energy will build up and the cycle repeats.

Standard equipment installation of micro-electroshock system.

Electrified Structures

The electrified structures were developed to provide different designs to match the architecture of different pole structures and evaluate which provided the best solutions:

- Vertical structure — This was developed to be applied to thin poles.

- Prism structure — This is best suited for poles with wider conductor spacing and on poles taller than 24 m (78.7 ft).

- Oblique structure — This is an electrified comb-type or ladder-type grid with a slope of 30 degrees to prevent the stork from attempting to build a nest. This structure is best suited for concrete supports.

- Oblique structure for metal poles — This structure is easier and focuses the electrified comb type or ladder type on the crossarm.

Electrified structures developed and tested and installed. (From left to right; Vertical structure; Prism structure; Oblique structure; Oblique structure for metal poles.

Poles in several problematic places on the distribution overhead lines were selected for a validation test. Two poles were equipped with vertical structures and another two with prism structures, both were very lightweight structures. However, the storks managed to start their nesting activity on these structures, so the electrode positions had to be moved to the top of the structure. Following this modification, the systems proved to be efficient at preventing storks from roosting and nesting.

One concrete pole and a metal tower were equipped with these devices. Both proved totally efficient at preventing storks from roosting and nesting.

These structures were more complex, heavier and expensive. However, the main issue was placement on the pole structures above 25 m (82 ft), which required more sophisticated lifting equipment.

Stork nesting over initial electrode position and electrode position modification.

Net Present Value

EDP-Distribuição conducted a study on micro-electroshock system costs, including installation and maintenance over 10 years, on the lines with the highest number of stork incidents over the last five years. The utility concluded a case-by-case analysis is necessary to determine the real profits of a micro-electrical discharge system. The net present value analysis showed replacing all the traditional prevention equipment with a micro-electroshock system typically would be negative.

The Results

The field trials have demonstrated controlled micro-electrical discharges, tested on a variety of birds, proved to be the most appropriate method to prevent electrocution and nesting. There are no records to suggest a negative impact on birds near any of the installed equipment. Therefore, the different types of solutions adapted to different tower structures proved to be effective.

EDP-D concluded the new technology was very effective in controlling stork roosting and nesting on protected locations, notwithstanding a few failed nesting attempts. It was observed the micro-electroshock systems are highly effective on white stork perching prevention, if the stork receives the unpleasant experience on the first landing.

Furthermore, the micro-electroshock systems proved to be effective any time of the year. Since storks typically find their nesting places by the second week in November, it is recommended the equipment be installed before then.

Selected micro-electroshock market solution installed.

Taking into consideration the net present value analysis, it was concluded a case-by-case study is necessary to determine the real profits of the micro-electrical discharge system comparing to traditional prevention equipment, since the analysis showed replacing all traditional prevention equipment with micro-electroshock systems typically would be negative.

Acknowledgements

This project was financially supported under the scope of Plano de Promoção do Desempenho Ambiental da ERSE, program 27 (a stork-protection strategy for avifauna) and EDP-D. We also are indebted to the Institute for Nature Conservation and Forests, the governmental body responsible for nature conservation and biodiversity policies as well as the management of protected areas, for its valuable contribution.The authors also wish to thank, among others, Magalhães Alves, Acácio Rico,Margarete Garcia, Hernani Vale and Joana Bernardo for their help and collaboration as well as Luís M.G. Maricato, Aníbal T. De Almeida and Vítor M.C. Madeira of the Universidade de Coimbra for their support in preparing this article.

For more information:

EDP-D | www.edpdistribuicao.pt

About the Author

Pedro.Carreira

Pedro Carreira holds a degree in electrical engineering specialized in telecommunication (2000), from Faculty of Sciences and Technology — University of Coimbra, and PDE from AESE Business School (2015). From 2001 to 2007, he has performed several roles in the Telecommunication Department of EDP Distribuição as critical communications infrastructures investment and project manager. From 2007 to 2013, he joined the Innovation and Development Department at EDP-Distribuição, which acts as an enabler of new technologies, developing and testing innovative and pioneer technologies, as project manager, assuming since 2013 the role of associate director. Since July 2016, he has been associate director in the Technology Department, implementing the EDP-Distribuição Technological Knowledge Management System.

Ana C.Janeiro

Ana Carolina Janeiro currently works as an electrical engineer at EDP-Distribuição — Energia S.A. She previously spent five months working as a researcher in the Institute for Systems and Computer Engineering, Technology and Science. Carolina Janeiro received her MSEE degree from the faculty of engineering at the University of Porto in 2014.

Pedro.Gouveia

Pedro Gouveia graduated in electrical engineering from Instituto Superior Técnico, Lisbon’s technical university. After graduation, he worked at EDP Inovação S.A., where he was involved in several research and development projects related to home automation and smart grids at the level of technology evaluation, market studies, and economic-feasibility analysis. Since 2018, Gouveia has worked in the smart grid department at EDP-Distribuição — Energia S.A.S.A.