Spacer Systems Get a New Connector

The overhead spacer cable and open tree wire systems, with medium-voltage covered conductors, were first used on medium-voltage networks more than 25 years ago. Covered wire was originally introduced to improve reliability for critical sections of the traditional medium-voltage networks with bare conductors, particularly when the overhead lines were routed along wooded roadsides and through forested rights-of-way. However, several utilities have experienced issues with interconnecting cables, namely with connectors that have developed faults, resulting in an adverse impact on the reliability of medium-voltage overhead line networks.

To resolve this problem, a collaborative three-year research and development (R&D) program, involving the use of research facilities at three universities, was established. Supported by field trials at two large distribution utilities experiencing abnormally high connector failure rates and issues stripping the conductors, a new insulation piercing connector (IPC) designed for spacer system applications has been developed.

Utility Experience

The first distribution utility to participate in the field trials was Emera Maine, a wholly owned subsidiary of Emera, formed by the integration of Bangor Hydro-Electric and Maine Public Service. Emera Maine provides T&D services to 159,000 customers in northern and eastern Maine. The U.S. utility first began using medium-voltage covered conductors (MVCC) in distribution networks to reduce customer outages from tree contact with overhead lines and increase system resiliency during snowstorms and blizzards in the region. Another issue affecting customer reliability and power quality that Emera Maine needed to address was the negative impact on secondary connections as a direct result of salt mist in coastal areas, causing corrosion-related outages and poor power quality on secondary networks.

The second distribution utility to participate in the field trials was CPFL Energia S.A., the largest non-state-owned group of utilities for the generation and distribution of electricity in Brazil and the third-largest Brazilian electric utility supplying some 7.7 million customers. CPFL started using MVCC for high-priority connections and reinforced the network with covered conductors, solving safety issues and securing critical connections, mainly to military or government facilities.

Initial Options

The available MVCC solutions have evolved favorably over time, offering a cost-effective and reliable solution more comparable with medium-voltage underground cable systems. Although cable manufacturers have improved cable technology by reducing the tracking effects and increasing the admissible voltage as well as the conductor working temperatures, few solutions easily interconnect these cables and maintain acceptable in-service performance within MVCC distribution networks. This includes primary taps and customer transformers initially designed for bare conductor networks. These products are not watertight and induce a breach in the overall protection of MVCC networks. Because of this insecure design, one of the essential benefits of a MVCC system is compromised.

The use of connectors primarily designed for bare conductors is problematic because it requires cable stripping, which can be hazardous to workers and requires appropriate safety precautions to be taken. Cable stripping is a difficult procedure because the insulation thickness can be up to 8 mm (0.315 inches) and requires substantial strength, even with the proper tools to remove the thermoplastic covering correctly. This can be especially difficult in cold-weather climates, as the covering is mechanically harder than normal.

The stripping requirement poses several significant safety, ergonomic and operational issues for linemen and utility operators. Depending on the situation, the cable requires rigorous, meticulous preparation, and a proper stripping tool with the correct accessories is not always available. There are situations where the stripping knife can damage the outlying strands, reducing the cable’s minimum breaking load and current-carrying capacity. Depending on the network voltage, these stripping operations must be performed with thick safety gloves or live-line hot sticks.

The lack of adapted, dedicated interconnection options is often a major restraint for the implementation of MVCC networks. For example, in December 2011, CPFL found a significant number of aluminum wedge connectors overheating.

Alternative Connectors

Both CPFL and Emera Maine began searching for an alternative interconnection solution that would avoid cable stripping and secure a watertight covering for the connector. Both were also committed to conducting field trials to collect feedback data from field crews to assess the installation experiences and electrical performance of alternative connector solutions. At completion of the field trials, both utilities selected IPCs for their MVCC networks.

For Emera Maine, the successful deployment of IPCs on its secondary networks for nearly 20 years provided an extra level of confidence with this new application on primary distribution connections. Manufactured by Sicame Corp., the IPCs allow a strip-free installation while keeping the connection area watertight, thus making bimetallic connections possible. Moreover, they do not require any special tools. They also eliminate the need for specialized training and highly skilled workers while avoiding key ergonomic issues. Overall, IPCs are safer for workers because they use shear-bolt technology, which ensures a highly reliable and consistent installation. They also have an integrated hard cap that cannot be removed once the connectors are installed.

While IPCs solve major issues for utility engineering and operational personnel, they also meet field crew expectations thanks to their ergonomic design and straightforward installation procedures.

Performance Validations

CPFL conducted long-term tests in its laboratories in Ribeirão Preto and Campinas, São Paulo, Brazil, by installing IPCs in some primary circuits and testing the connectors to the maximum current limit. In the following years, CPFL took temperature readings on these connectors. The results obtained were deemed satisfactory, with the IPCs outperforming wedge connectors operating at the same maximum current limit.

Emera Maine began a trial installation of IPCs on a 15-kV distribution network 10 years ago. This type of connector has resolved the utility’s concerns with performance issues experienced using alternate solutions as well as the ergonomic and safety issues line crews had with stripping covered conductor. The insulation piercing solution has been welcomed and appreciated the most by field crews. These connectors quickly became their preferred method of making primary connections.

Tracking Effect

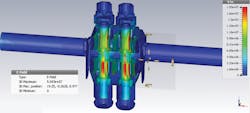

The last stage of finalizing this technology was to secure performances versus electrical stress over time. IPCs bring ease of installation with strip-free watertight connections. However, it was important to determine their resistance to tracking and partial discharges.

Fifteen years of field experience has validated the ability of IPCs to resist tracking in most networks. However, the partial discharge and tracking phenomenon is complex with interdependent and varied parameters. Also, the fact there are no standards regarding tracking resistance makes this topic even more complex.

To compensate for the lack of information and standardized tests, utilities and manufacturers have shared their experiences on tracking, especially on how it appears and its implications. Complete modeling of the electrical field has enabled further understanding to control this tracking and electrical stress phenomenon. Manufacturers have been able to improve their IPC design incrementally and satisfy an additional tracking resistance requirement: 1000 hours in a 35-kV salt spray chamber. This has been a significant and welcomed development especially for CPFL, whose MVCC networks include 25-kV networks erected in polluted areas.

New Connectors

The new IPCs, developed by Sicame for medium-voltage spacer systems, meet all the requirements and expectations of Emera Maine and CPFL, despite the utilities different environments, networks and working methods. Because of their wide cable range and watertight connection area, the IPCs can be used to connect all types and configurations of networks.

IPCs now offer the easiest and safest solution on the market for field crew installation. With enhanced anti-tracking characteristics, IPCs also offer the assurance of a consistent, robust and stable connection for the lifetime of the network, even when installed in the toughest environments.

Acknowledgement

The authors wish to thank Vivien Rineau of Sicame for help and support in the preparation of this article. ♦

Marcelo de Moraes holds an electrical engineering degree and has a MBA degree in project management from Fundação Getúlio Vargas. He joined CPFL Energia S.A. in 1985, initially starting in the substations maintenance department, prior to developing standards for the distribution network. Moraes is now responsible for technical standards under CPFL’s power distribution vice presidency.

Bruce E. Philbrick holds a BSEET degree from the University of Maine and is a licensed professional engineer in the state of Maine, with some 30 years of experience in power systems. He has held various positions within Emera Maine over the past 25 years and currently undertakes engineering design, system impact studies and construction coordination of grid connections for distributed generation and large power customers. Philbrick also is responsible for transmission line design, planning, power quality and construction standards.

Check out the October 2017 issue for more articles, news and commentary.

About the Author

Marcelo de Moraes

Marcelo de Moraes holds an electrical engineering degree and has a MBA degree in project management from Fundação Getúlio Vargas. He joined CPFL Energia S.A. in 1985, initially starting in the substations maintenance department, prior to developing standards for the distribution network. Moraes is now responsible for technical standards under CPFL’s power distribution vice presidency.

Bruce E. Philbrick

Bruce E. Philbrick holds a BSEET degree from the University of Maine and is a licensed professional engineer in the state of Maine, with some 30 years of experience in power systems. He has held various positions within Emera Maine over the past 25 years and currently undertakes engineering design, system impact studies and construction coordination of grid connections for distributed generation and large power customers. Philbrick also is responsible for transmission line design, planning, power quality and construction standards.