“The greatest engineering achievement of the 20th Century" declared the National Academy of Engineering. Indeed, the US electric grid has helped the nation thrive for over a hundred years. Understandably, much of that aging electric infrastructure now needs to be expanded, refurbished or replaced. The U.S. is expected to spend over $2.1 trillion by 2035 on grid technologies and infrastructure, according to the International Energy Agency.

Faced with the size of that task, it’s no wonder that utilities and contractors are asking tool manufacturers to improve worker safety and increase efficiency through both adaptation and adoption of new technologies in their product design. Good ideas are bubbling up from the field, helping purchasing departments to make better decisions and educate manufacturers.

There’s a revolution in tool design and three Textron companies -Sherman + Reilly, HD Electric Company and Greenlee utility are leading the way!

Batteries, Not Hoses

We all know how handy the battery powered drill has become. Advanced battery technologies make possible self-contained and lighter weight power line tools. By using battery powered cable crimpers and cutters, the worker is free to move safely to optimal postures and positions to get the work done. And the lighter weight, balance points and other ergonomic factors improve comfort and efficiency. There are a number of “smart” improvements being made to battery tools as well, including miniature pressure sensors that can monitor the actual crimping force and emit both an audible and visual alarm when a crimp is below specifications. Battery diagnostics help the user optimally time battery change outs. Overall battery condition is also monitored.

Safety First

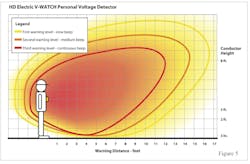

Utility lineworkers are exposed to all sorts of hazardous working conditions – no wonder their job is listed as one of the top ten most dangerous positions. Miniaturized “smart” sensors and transceivers are now available that can identify the presence of electric fields in the work area. A wireless, mesh network of these devices can protect a crew’s working area, setting off alarms when a potentially dangerous field strength is detected and the source located. Individual sensors can even be worn to alarm the wearer when approaching a dangerous voltage source. A similar unit can be mounted on a bucket truck to help avoid contact with unexpected but dangerous voltages.

Of course, these devices can be lifesaving when used while assessing storm damage or other urgent repair, particularly at night. But the extra safety margin can expedite non-emergency work also, such as line additions and refurbishment.

New tool communication and sensor technologies have also opened up many other opportunities. For example, a worker taking a phase reading with a hotstick mounted meter can have the reading verified by another crewmember nearby or even across the street - the meters having a secure, wireless connection.

Figure 1 The Sherman + Reilly line of battery-powered crimping tools provide one-hand operation and are equipped with Intelli-crimp technology to monitor crimping force.

The wave of modernization isn’t restricted to just hand tools. Depending on the manufacturer, fully-enclosed cab designs are becoming the new standard with a full 360 degree viewing area. Seats are comfortable and adjustable. Controls and gauges are ergonomically designed and the cab is quieter, making for clearer, more accurate radio and voice communication. The cabs are also fully insulated to protect the operator against extreme temperatures as well as shock hazard from energized equipment.

These improvements result in less operator fatigue, more safety, and higher productivity.

Enhanced Asset Management

With on-board power supply and Bluetooth or another communication network, each tool becomes a member of, what we might call, with tongue-in-cheek, a local “ioT” (internet of Tools). Diagnostics are available to not only the user, but also to a nearby field data collection point, usually a laptop. Individual tool crimp or jaw pressures and other diagnostics are recorded along with GPS location. These are available for local print-out. All the data can also be sent to the company’s tool management system. In fact, it’s possible to keep track of tool inventory and tool operating/maintenance data across the company-wide enterprise.

These new possibilities are an asset manager’s dream. Until recently the best that could be done was hand-entered data on a spreadsheet!

Figure 2 The HD Electric Company’s V-Watch Personal Voltage Detector alerts workers to high electric fields which may indicate nearby high voltages.

Manufacturer Role

Sherman + Reilly, HD Electric Company and Greenlee Utility know that the best ideas come from actual users. “That’s why we are working with utilities and powerline construction companies to get clear, effective communication channels from the field,” said Ryan Berg, Director of Product Management for the Textron utility brands The feedback we have received from the tool committees, made up of experienced lineworkers who know what they need to do their job more safely and more efficiently, has provided key features for our new tools Our role is to listen carefully and then design our products accordingly. “

Advanced power supply, new sensors, ergonomics and networked tools – all are resulting in greater safety and more efficiency.