What is Horizontal Drilling, and Why is it Important?

Horizontal directional drilling (HDD) has gained popularity in the power delivery industry for undergrounding transmission and distribution lines primarily to minimize extended power outages in the aftermath of a large storm or hurricane. The advantages also include the less disruptive mental and environment impact to the daily lives of utility customers and communities. This multi-part series will guide you through the less talked about jobsite concerns.

HDD is a less impactful method to install underground pipes rather than digging an open trench to bury the pipe. The use of this method greatly reduces the environ, and disruption to roadways and other existing infrastructure during construction.

Martin Cherrington is said to be the person who came up with the idea of HDD for the utilities in the 1960s. After making the first HDD machine, Cherrington started making road bores in California for the Sacramento Municipal Utility District (SMUD). However, the most crucial feat he accomplished was completing a Horizontal Directional Drilling project under the Pajaro River for Pacific Gas & Electric Co. at 500 feet in the early 1970s.

Precisely 36 crossings were accomplished using this technique between 1971 and 1979, and all of them took place in the United States. In addition, there have been more than 175 crossings in the following seven years in South America, Europe, Africa, Asia, and the Pacific. Further, several companies are currently competing in the market, and there are well over 500 crossings.

What is Horizontal Directional Drilling?

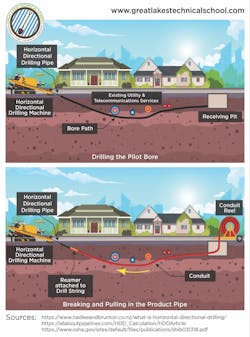

Horizontal Directional Drilling (HDD) is a technique of installing subsurface pipelines, cables, and utility conduits without trenches or other excavation. Using a directional drilling machine and its related attachments, it is possible to precisely drill along the desired bore path and back ream the necessary pipe to meet the utilities or telecommunications placement specifications.

In simple words, it is also known as directional boring, which refers to a novel approach for drilling sites to obtain oil while exerting less effort and energy than other directional drilling efforts. In projects where drilling companies choose to use horizontal drilling, a directional drilling machine is used to drill through a specific path that has been pre-determined.

Several advantages are provided to both the drill site and the property owners where the drilling is taking place due to this method.

Why is Horizontal Directional Drilling Important?

Horizontal directional drilling (HDD) is a relatively new telecommunications and utility installation technology. It allows for greater precision and flexibility in the placement. In addition, it eliminates the necessity of costly digging and the need for large crews, road closures, and other complications associated with traditional digging and pipe installation.

However, the old method of digging down to install pipes and utilities is known as open-cut, and it is significantly more disruptive than HDD but possesses other drawbacks. At the same time, horizontal directional drilling for your repair, maintenance, or installation job is likely the most cost-effective approach.

Here we look at some of the reasons as to why is it essential:

Endurance

It is more difficult for HDDs to be damaged during installation because of the adoption of durable materials with longer lives and better positioning accuracy. Unfortunately, pipes have run under bridges in some regions, those that straddle rivers, exposing them to the weather and reducing their lifespan by 50% to 75%.

HDD makes it easy to install under rivers, driveways, etc., and burying pipe and utility lines increases their long-term endurance.

Reduced Costs

HDD is speedier, which lowers the cost of storage. As a bonus, less dirt is disturbed, which reduces the amount of land that needs to be restored. As a result of HDD's reduced operator requirements, there is also a reduction in labor costs.

HDD doesn't rely on renting backhoes and other heavy equipment; hence less equipment is needed. This translates to lower expenses. Therefore, it is more cost-effective in almost every way than open-cut drilling.

Reduced Disruption

Clean-up and time are both addressed by HDD. In addition, your landscaping will be protected because HDD requires less soil displacement and does not require digging the entire length of the pipe or line into your property.

At the beginning of the tube, a hole is dug, but no landscaping is torn up in the process. This allows you to spend less time and money on job clean-up and landscaping.

Flexible Location

When impediments are a problem, HDD can be used to lay pipes, water and sewer lines, and other utilities. Horizontal drilling, for example, makes it possible to run a cable or utility under a road, driveway, culvert, river, or in a place where the pipe must bend. As a result, a conduit may now be laid in areas where it was previously impossible or prohibitively expensive.

Less Contamination of the Soil

To avoid spreading soil contamination above ground during HDD drilling, horizontal directional drilling pushes soil to one side instead of bringing it to the surface. In addition, since the pipe connections are long-lasting, contaminated soil should not get into the pipes. As a result, the contamination risk from conventional vertical drilling is substantially more significant.

Fewer Permit Problems

To gain permission to carry out HDD, either for residential or commercial purposes, the process is much more streamlined because it is more similar to traditional drilling regarding the amount of work necessary and the amount of debris produced due to the operation.

Final Thoughts

In short, HDD will become more and more critical as a way to get around busy cities at a lower cost and without causing property damage. It will become important as utility companies try out or move to other energy sources. There should be the same rules for HDD crews installing telecommunications, power, natural gas, etc. Moreover, utility owners have to ensure that the contractor and the contractor's subcontractor are qualified to complete the work when they are outsourcing a project.

In Part 2 we will discuss what to do when the design engineers hand you the bore plans.

John F Hendershot is the former CEO of DIG-IT, INC in Hastings, Michigan, as well as former president of the Great Lakes Trenchless Association. John has proposed that in-depth underground utilities and telecommunications technical school be built within the Grand Rapids, Michigan area. He believes this effort is the responsibility of all utilities & telecommunications companies as well as construction contractors within the industry. For more information you can email John at [email protected]

About the Author

John F Hendershot

John F Hendershot is the former CEO of DIG-IT, INC in Hastings, Michigan, as well as former president of the Great Lakes Trenchless Association. John has proposed that in-depth underground utilities and telecommunications technical school be built within the Grand Rapids, Michigan area. He believes this effort is the responsibility of all utilities & telecommunications companies as well as construction contractors within the industry. For more information you can email John at [email protected]