A Model for Reducing Storm Recovery Time

When Rodney Blevins left the Dominion Energy regional operations center on June 29, 2012, he knew a storm was coming but was not worried. With routine storm planning and preparation, the operations team in place was ready. He felt confident he could leave for a long-awaited nine-day tuna fishing trip.

However, this particular storm was no run-of-the-mill weather event, as he had anticipated. It was the 2012 derecho, a line of thunderstorms that swept across 10 states with the force of a hurricane — damaging homes, flooding roads, and causing widespread utility outages. The event ultimately changed the course of Dominion Energy’s electric service reliability history and prompted the utility to rethink its operations for the future. Needless to say, the fishing trip never happened.

Wind Of Change

In 2012, most people, besides weather forecasters, were not familiar with the term “derecho.” Blevins, who is now president of Dominion Energy South Carolina, surely was not. At the time, he was a 25-year electric industry veteran who had held several positions across the utility’s distribution business. His responsibilities included the system storm center, where he had been involved in every major storm event since 1999. Early in his career, he cut his teeth on storm restorations along the Virginia I-95 corridor. In that time, he saw it all, Blevins said.

The June 2012 Mid-Atlantic and Midwest derecho was one of the deadliest and most destructive fast-moving thunderstorms in North American history. It tracked across a large portion of the Midwest, and then moved across the central Appalachians into the mid-Atlantic states on the afternoon and evening of June 29 and early morning of June 30.

The severe windstorm resulted in 22 deaths, millions of power outages across the affected regions and damages estimated at US$2.9 billion. Approximately 1 million customers lost power in Virginia for eight days, the largest outage in the state’s history not related to a hurricane. The only outages with a greater impact were Hurricane Isabel in 2003 (a 15-day restoration) and Hurricane Irene in 2011 (a nine-day restoration). To make matters worse, most areas were suffering through an extended heat wave.

“There’s always the potential for a storm. That’s just life in Virginia,” Blevins said. “But for this one, the calls started almost immediately. We had just recovered from Irene the year before. We knew it was time to look at things differently.”

Digging For Answers

Undergrounding power lines is not new. In fact, The Vepcovian, an employee newsletter for Dominion Energy’s forerunner Virginia Electric & Power Co. (VEPCO), ran a story titled “Wouldn’t it Be Nice!...To Have Wires Underground?” in June 1955.

The 1955 story asked the same question customers and policy makers asked after the 2012 derecho: “Why can’t all overhead wires be underground?”

Utilities have been placing lines underground for decades. However, much of the first-generation efforts suffered from poor reliability, Blevins recalled. Advances in technology have since made newer generations of cable stronger and more reliable. Additionally, advances in installation methods and the use of conduit have extended the life of underground cable further.

With these advances, most new commercial and subdivision electric installation is now underground. However, in older American neighborhoods, most power and communications lines remain suspended from utility poles, making them vulnerable to windstorms and ice storms.

After the derecho, customers across Dominion Energy’s Virginia service territory were fed up with lengthy outages and telling members of the Virginia General Assembly about their displeasure. Dominion Energy was directed by lawmakers to study what it would cost to put all overhead utilities underground. Blevins was asked to form a Six Sigma process improvement team to get to work on developing an answer.

The team estimated a cost of US$200 billion for an all-or-nothing approach to convert all lines to underground, which was not deemed prudent. However, the team persisted and explored a plan to improve storm resiliency in a strategic, cost-effective manner.

The process improvement team consisted of Dominion Energy electric industry veterans that worked in design, right-of-way, reliability and communications. Much of the financial and systems analysis was led by Les Carter, who was a reliability manager at the time.

The team considered the system:

- 58,000 miles (93,342 km) of distribution lines

- 40,000 miles (64,374 km) of overhead lines, half of which were tap lines

- Significant annual infrastructure investments already underway

- Significant outage exposure on tap lines.

According to Carter, the utility’s ongoing reliability initiatives addressed the system average interruption duration index (SAIDI). However, the team landed on the notion that the focus instead should be on the total length of restoration (TLR). In other words, how can the utility reduce the amount of work necessary to restore service as quickly as possible?

“We spent most of 2013 examining every inch of our system. Where were we seeing the most damage and what took the longest to restore?” asked Carter. “Ultimately, the data suggested converting just 10% of the system, or 4000 miles (6437 km), of the most outage-prone tap/lateral lines could reduce restoration times following severe weather events by up to 50%. At the time, not many utilities focused on TLR. We found that SAIDI just was not the best measure for big storms. TLR measures the time from last out to last restored.”

Getting Strategic

In late 2013, Dominion Energy developed the strategic underground program (SUP). After months of internal analysis and work with stakeholders, the framework for the solution was finalized and submitted to the Virginia General Assembly. The measure was overwhelmingly approved and included a workable cost-recovery method as well as strict provisions and metrics:

- Cost per mile — legislative limit of no more than US$750,000

- Cost per total customer — legislative limit of no more than US$20,000.

Blevins moved quickly to name Alan Bradshaw as the new director of electric distribution underground, coming over from a stint as manager of the regional operations center. He was able to keep most of the members of the Six Sigma team and they quickly got to work fine-tuning what is now one of the most successful electric underground programs in America.

Several operational questions still had to be decided. Which specific lines should be targeted? Should the work be done with in-house resources or contracted out? What would be the best way to secure easements? How should the utility communicate with customers about the initiative and how often? All these decisions had to be made while continuing to work with legislators and regulators, who were laser focused on every facet of the initiative’s rollout.

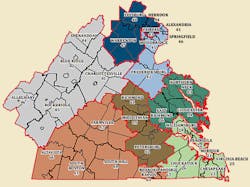

What emerged in 2014 as the team prepared to put the first shovel in the ground was a sophisticated organization that drilled down and settled on looking at a 10-year outage data set to target which lines to place underground. The service territory was divided into seven work areas, each with a dedicated project manager, technical coordinator (TC) and marketing communications coordinator (MCC).

Mostly former designers, TCs got busy taking the results of the data analysis, which identified qualifying tap lines, and creating workable projects. They reviewed outage history and looked at the total area circuitry. Then they performed site visits, as what looks good on Google Maps may not actually work in the field and vice versa.

With the focus on outage events per mile, the TCs went through a laundry list of constructability issues, including confirming the right-of-way length, terminal pole locations, and general terrain or other physical obstacles to determine the feasibility of working a particular tap line.

The TC is the technical point throughout the life of the project, including reviewing final design. In many cases, multiple taps or line segments are bundled together in one project. For example, a given subdivision may have nine taps. The best solution may be to convert all of them to underground or just some. Once that is decided, the TC creates the scope — an initial route of the planned circuitry and constructability items of note.

Area managers and project managers have oversight of the work plan, manage contractors and ensure their area achieves the goals each quarter related to counts for easements closed, miles designed, miles converted and overhead miles removed.

The marketing and communications team is the point of contact for all customer communications. They have developed through the years structured communications for all scenarios, including a milestone-based communication plan. This ensures every customer gets consistent messaging throughout the life cycle of a project.

According to Bradshaw, the SUP started slowly but quickly built steam after an initial adjustment period to see what worked and what did not. It became clear early on that using existing in-house resources hampered the speed needed to scope and design projects. Therefore, one of the utility’s major decisions was to outsource key components of the program.

Dominion Energy contracted with a vendor for each of the seven work areas. Under the oversight of the utility’s project manager for a given work area, the vendor is responsible for professional services and construction. From a professional services standpoint, the vendor acquires easements, performs surveys, obtains permits, gets access to utility locations, and completes detailed designs from the projects scopes and makes any necessary adjustments based on obtained easements. The vendor’s construction responsibilities include drilling, terminating, cutovers, removal of overhead lines and, of course, restoration of property.

The utility also had early concerns that never proved to be impediments to the success of the SUP. One concern was whether customers would provide needed easements and equipment locations, which they have. There also was the matter of how to connect the new, larger lines to older 60-A meters. That problem was solved by adding adapters at no cost to the customer.

Others worried developing joint-use projects with fellow utilities would prove to be a hindrance. Karen Kinslow, Dominion Energy’s director of grid resiliency and undergrounding, which absorbed the SUP as part of a recent utility reorganization, noted those early worries proved to be minor hurdles. While the company developed joint installation processes to leverage common work activities and included incremental pricing solutions, and checks with other utilities before contacting customers at the start of each undergrounding project, in the end, most choose to stay overhead as their business and operation models are different.

Early concerns that customers would not agree to easements if the cable and phone lines remained overhead did not materialize, as customers understood the reliability advantages in the project as the utility described them.

Another challenge that had to be addressed was the management of information. When conducting the first analysis of the candidate tap lines (those that met the criteria), information on those devices and their associated data (length, number of customers, outage history) was entered into a simple database.

At the time, multiple existing Dominion Energy systems and databases were used to track a project. Because of the emerging success of the program, a separate work management system was built. The strategic underground management system (SUMS) automates many of the steps, has one central record everyone can access and keeps all teams on track.

The Customer is King

One thing Blevins, Bradshaw and Kinslow all agree on is the customer must always be the focal point of the underground efforts and communication is critically important. One of the great benefits of SUMS, beyond monitoring the status of all work, is tracking communication.

SUMS efficiently sends out the milestone letters and postcards. All communications — calls, emails and letters — are logged into SUMS. Therefore, if a customer calls a MCC, whose contact information is on all communications for the duration of the project, and the customer had previous conversations with one of the vendors, the MCC can pull up the notes in SUMS while talking to the customer and get up to speed.

If there are special requests from the customer — such as do not work on my property on a Tuesday or do not park trucks in this area — those notes are entered in SUMS. Then when the next team (design or construction) goes out, they know the request and it does not slip through the cracks.

Although Blevins is years removed from the SUP, he believes that, leading up to the creation of the SUP and having worked through Hurricane Irene and the 2012 derecho, the commitment to customer service has only gotten stronger.

“The work that all utilities do is a form of public service,” he noted. “I have missed everything important to my family at least once. We don’t have the choice during a major storm to say, ‘No thanks.’ That commitment colors the way Dominion Energy does business.”

As a measure of the program’s outreach in customer communication, Dominion Energy was awarded the 2019 Leadership in Smart Grid Customer Education Innovation Award by The Smart Grid Customer Education Symposium.

Greatest Form of Flattery

A sure sign of the success of the Dominion Energy SUP is the number of utilities that have been in contact over the years to learn how it can be adapted in their states. Several have duplicated many facets of the program.

“The reliability improvement is clear and unambiguous,” Kinslow said. “Some of the tap lines being converted to underground can be the most difficult to access and time consuming to restore. Reducing the number of damage locations, especially those in difficult-to-access areas, leads to a cascading reduction in the time required to restore power for many customers, not just the ones served by converted lines.”

As of September 2020, Dominion Energy has invested US$748 million and moved nearly 4000 separate tap lines, totaling 1502 miles (2417 km), underground. By converting these tap lines to underground, Dominion Energy has, in essence, eliminated 2139 annual events.

Karen Kinslow is director of grid resiliency at Dominion Energy. She has held previous technical and leadership roles at Dominion Energy in system reliability and finance. Prior to that, she was a consultant at UMS Group Inc., where she supported more than 100 utilities with performance improvement initiatives. Kinslow earned her bachelor’s degree in industrial and management engineering from Rensselaer Polytechnic Institute.

Tony Robinson is a marketing communications coordinator for the strategic underground program at Dominion Energy. Previously, he was president of Robinson Public Affairs, providing public relations and stakeholder engagement counsel for government and economic development officials. Prior to opening his consulting firm, he completed a 20-year public service career as director of public affairs for the mayor and city administrator of the District of Columbia, where he managed communications and media relations activities.

About the Author

Karen Kinslow

Karen Kinslow is director of grid resiliency at Dominion Energy. She has held previous technical and leadership roles at Dominion Energy in system reliability and finance. Prior to that, she was a consultant at UMS Group Inc., where she supported more than 100 utilities with performance improvement initiatives. Kinslow earned her bachelor’s degree in industrial and management engineering from Rensselaer Polytechnic Institute.

Tony Robinson

Tony Robinson is marketing communications coordinator for the strategic underground program at Dominion Energy. Previously, he was president of Robinson Public Affairs, providing public relations and stakeholder engagement counsel for government and economic development officials. Prior to opening his consulting firm, he completed a 20-year public service career as director of public affairs for the mayor and city administrator of the District of Columbia, where he managed communications and media relations activities.