Estimate the Lifetime of MV Underground Cable

Based on their understanding of the importance of a healthy and reliable cable network, distribution system operators (DSOs) strive to meet two major objectives: minimize maintenance costs while maintaining high system reliability. Today, DSOs must manage scarce resources, high standards in terms of supply security and aging cable networks that are becoming more complex. Additionally, the transition to renewable energy sources has increased loading on cable networks.

Electric utilities face the task of operating their aging networks at the lowest cost without incurring fault outages. Very low frequency (VLF) cable diagnostic techniques are an effective tool to evaluate the condition of cable, which can help a utility to decide whether partial or sectional replacement of a cable is needed urgently. However, estimating the remaining lifetime of the cable, while challenging, can take it another step further by enabling DSOs to manage their investments and resources even more effectively.

Cable Management

The largest electric utility in South Korea, Korea Electric Power Corp. (KEPCO) previously adopted time-based management (TBM) for its infrastructure and equipment, including medium-voltage (MV) underground cable. According to this policy, MV cable had to be replaced when the in-service installation period exceeded the 30-year cable design lifetime. However, this policy proved to be impossible to implement over time because of the quantity of cable involved and investment required. The utility decided to move toward risk-based management (RBM) and condition-based management (CBM) to manage its investments more efficiently.

DSOs use various methods to test underground cable and assess their condition. For example, with the isothermal relaxation current (IRC) analysis method, the amplitude of the residual discharge current is measured when a direct-current (dc) voltage is applied to the cable. Another example is the measurement of the dielectric dissipation factor, known as the tan δ method. With this method, the phase angle difference between the voltage and loss current is measured when an alternating-current (ac) voltage is applied to the cable.

KEPCO currently uses the tan δ method for underground cable with a VLF test voltage at a frequency of 0.1 Hz. This test measures and analyses eight tan δ values at three voltage steps for a period of 80 seconds. The relatively short measurement period eliminates the external electromagnetic disturbances and is highly reproducible.

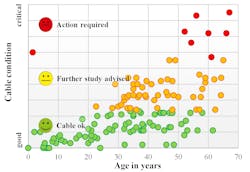

Adhering to IEEE standard 400.2-2013, the Guide for Field Testing of Shielded Power Cable Systems using Very Low Frequency, KEPCO uses the statuses of no action required, further study advised and action required to classify the condition of its underground cable.

These statuses are derived from combining three factors:

- Mean tan δ (MTD) for the measured eight tan δ values

- Delta tan δ (ΔTD) for the difference between the tan δvalues of high and low voltage and the standard deviation value (SDTD)

- Time stability of the eight tan δ values.

In 2011, based on VLF test results on 707 circuit-km (439 circuit-miles) of MV cable, KEPCO assigned an action-required status to 30.2%, or 214 circuit-km (133 circuit-miles), of MV cable. Based on a replacement cost of US$81,700/circuit-km ($131,477/circuit-mile), the total cost would be $17.5 million. Today, following this same logic and given the capacity to run the VLF test on even more cable, the amount of cable requiring action would be cost prohibitive.

The major disadvantage of these three statuses is they fail to provide guidance on the rate at which the cable will deteriorate, a factor closely linked to the cable installation’s surrounding environment and lifetime operating performance in terms of cable loading, overloading and short circuits, for example. Therefore, the barrier to risk management is the lack of knowledge on the speed at which a cable will degrade. In other words, what is the cable’s estimated remaining lifetime?

Remaining Lifetime

In 2015, KEPCO developed a methodology to estimate the remaining lifetime of MV underground cable. The utility did so after an extensive analysis of VLF tan δ diagnostic field-test results on some 15,000 sections of 22.9-kV cross-linked polyethylene (XLPE) insulated cable as well as similar types of cable and joints collected over many years. Based on the world’s largest VLF tan δ database, KEPCO decided to apply a statistical approach using the accumulated 45,000 tan δ test data sets (currently about 60,000 data sets).

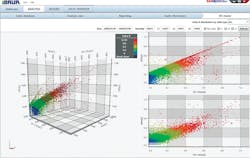

In addition to the three analysis parameters (MTD, ΔTD , SDTD), KEPCO applied the existing MTD and ΔTD as they were and then developed a new factor, TD-Skirt (time stability), which closely correlates with the insulation breakdown of the cable. A quantitative value of the change in the dissipation factor during the 80 seconds of measuring tan δ, TD-Skirt represents very sensitive time stability. Statistically, the probability of cable breakdown is very high when MTD, ΔTD and TD-Skirt are high values at the same time.

A three-axis space vector was applied as a method for synthesizing these three factors simultaneously in the same space. The vector length from the starting point, named Index R, was calculated to represent quantitatively the positions occupied by one data set in a space vector in which MTD, ΔTD and TD-Skirt are composed of X, Y and Z axes. For the tan δ data set that appears as a single point in the space vector, KEPCO confirmed it gradually moves linearly to a further position from the origin as the degree of failures increases in the logarithmic scale.

A cluster of tan δ data sets emerges within the three axes, and the tan δ data sets of the faulted cable are indicated by triangles. It is easy to see the larger the Index R, the greater the number of triangles. This results in a higher probability density of failures over a range of more than arbitrary Index R, in which the fault data begins to occur. The probability density is a clue that helps to derive the statistical lifetime limitation of cable.

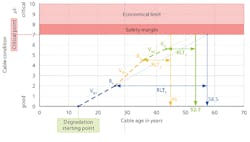

Based on its statistical evaluation, KEPCO concluded cable with less than 13 years in service do not exhibit signs of aging. Therefore, a degradation starting point can be defined beyond when aging is expected to start. The economical limit is set at a level where cable statistically fails and is expected to fail at any moment. The DSO builds in a margin of safety so this level is not reached.

Study Verification

To evaluate the logic of the cable condition classifications and the utility’s new estimation of the residual lifetime of these circuits, KEPCO performed a direct comparison with the IEEE 400.2-2013 criteria. Using the same database, KEPCO’s new lifetime logic found only 54 circuit-km (33.6 circuit-miles) of cable had a remaining lifetime of less than two years. According to IEEE 400.2-2013 field guide criteria, 201 circuit-km (125 circuit- miles) would need to be replaced, even though they were not in a critical state. Also, the study revealed the average cable lifetime in comparison with IEEE 400.2-2013 could be increased by 11 years.

Further study was conducted when some 11,000 km (6835 miles) of 22.9-kV cable, representing approximately 25% of the MV network in Korea, was diagnosed. The network failure rate of the not-yet-diagnosed cable was 3.37 failures/1000 km (621 miles), indicating a very healthy network. Cable in service for less than 13 years had a failure rate of 0.32 failures/1000 km. Cable subject to KEPCO’s algorithm of remaining lifetime indicated a rate of 0.29 unexpected faults/1000 km. These statistics emphasize the condition of KEPCO’s MV cable network, in which cable failures rarely occur.

Cable Management Policy

Today, KEPCO continues to use the methodology it developed in 2015 for estimating the remaining lifetime of cables. To maintain a conservative cable management policy, after considering the social responsibility it has to manage power throughout South Korea, the utility has designated Index R = 0.751, the point at which the failure probability is 5% of the economic lifetime limitation. Based on its experience, KEPCO has decided on a two-year remaining lifetime period for replacing cable. This period takes into consideration the time needed to replace the cables and errors in the lifetime estimation limitation.

In addition, KEPCO operates a unique central monitoring system to monitor the diagnostic mobile site for each of its 20 BAUR GmbH’s VLF diagnostic test vehicles in operation, providing remote assistance when needed. Moreover, it has established the tan δ data set as the database while developing and using its own software to manage the remaining lifetime of each cable in its network. The utility has found it is necessary to readjust the Index R by analyzing accumulated tan δ data sets periodically, because more accumulated data can improve the accuracy of the remaining lifetime estimation.

KEPCO has developed a software named statex, with the analysis algorithm and recommendations for subsequent measurement should be performed, or when work is required, manufactured by BAUR. This software is designed to reset the Index R according to changes in the facility environment or policy (for example, in times of budget tightening or fiscal expansion) with a wizard function that can set KEPCO’s own criteria based on accumulated data.

Cost Savings

KEPCO implements RBM and CBM by operating its management system based on the remaining lifetime of underground cables. As a result, it manages the remaining lifetime data for 13,000 circuit-km (8078 circuit-miles), or 31% of its 42,000 circuit-km (26,099 circuit-miles) of MV cable in service as of 2019, thereby reducing its maintenance budget of approximately $12.7 million every year. Also, it has achieved tangible results in terms of the cable failure rate, with a reduction of 53% (from 47 faults to 27 faults) in the average annual cable failure rate. Long term, it is expected this achievement will be even greater when the lifetime data is available for all MV cables in service.

The statistical approach developed by KEPCO to determine the remaining life of its MV underground cables is proven. In addition, the failure rate of cable subject to diagnostic testing has been reduced to a minimum. The potential of this new approach has not been fully realized yet in terms of the substantial economic savings that can occur as a result of deferring the premature replacement of seemingly healthy MV underground cables.

Acknowledgement

The authors wish to acknowledge all the support they received from Tobias Neier, Jens Knauel, Manfred Bawart and Martin Jenny, all from BAUR, in preparing this article and serving as coauthors of a paper on this development presented at CIRED 2019 in Madrid, Spain.

For more information:

BAUR | www.baur.eu

About the Author

Dongsub Kim

Dongsub Kim received a master’s degree from Hanyang University in Korea in 2000 and a PhD degree in technology policy from Yonsei University in 2014. He has been working at Korea Electric Power Corp. (KEPCO) since 1985 and now serves as senior executive vice president of business operations as a member of the board of directors. Previously, he was responsible for the distribution planning department and research institute as vice president.

Sung-min Kim

Sung-min Kim received his MSEE degree from Yonsei University in 2000. He joined Korea Electric Power Corp. (KEPCO) in 2003 and is now the general manager of the data science laboratory. His responsibilities have included underground facility operating planning as well as diagnosis and analysis. Sung-min Kim developed the utility’s power cable remaining lifetime estimating system.